Prefabricated beam connecting support and connecting method

A technology for connecting bearings and prefabricated beams, which is applied to building components, earthquake resistance, building types, etc., can solve the problems of difficult popularization of prefabricated beam cast-in-place joint reinforcement connection technology, low construction efficiency, poor practicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the essence of the present invention, the present invention will be further described below in conjunction with specific embodiments and drawings.

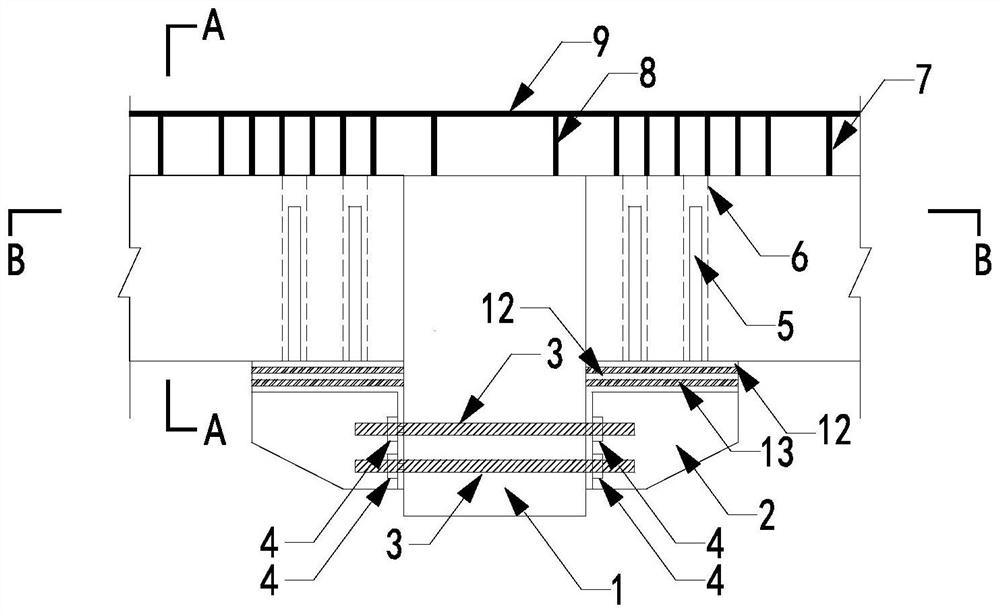

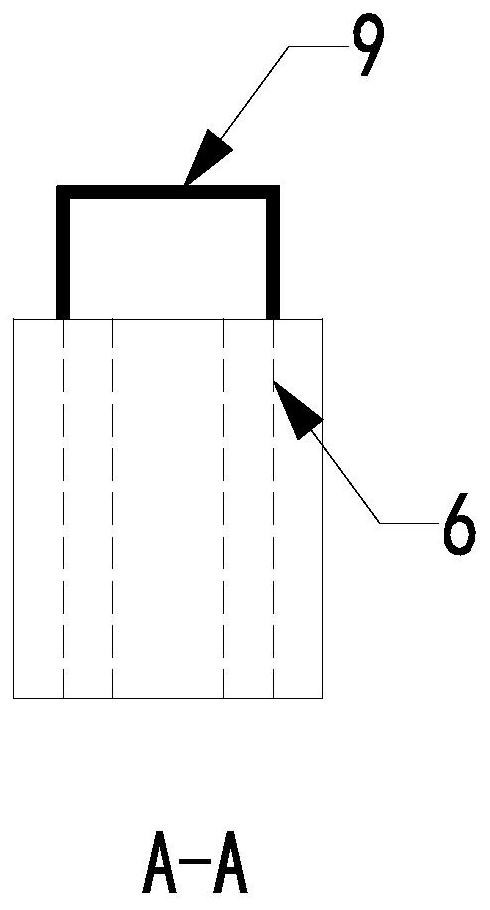

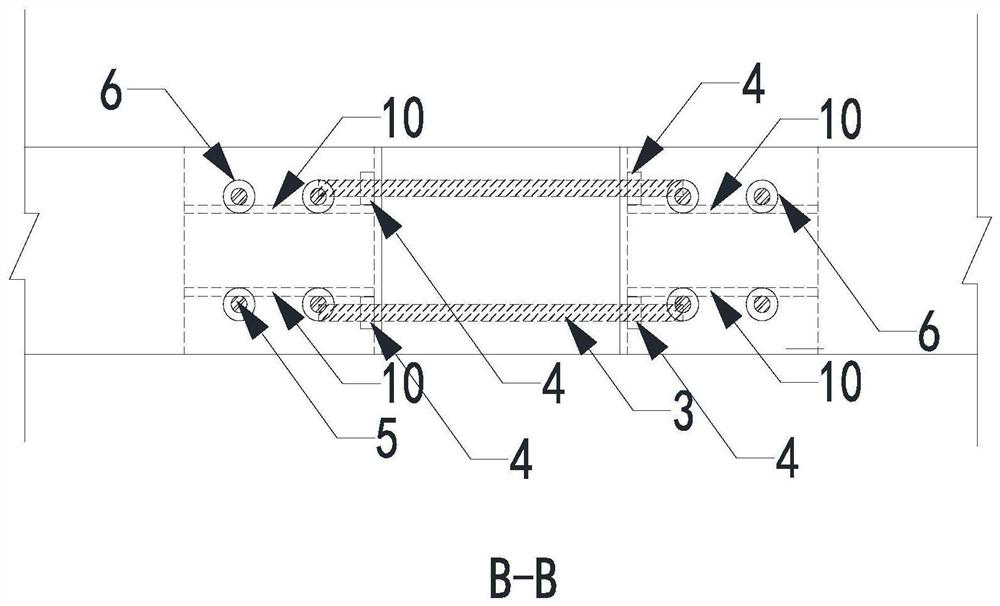

[0022] The invention is suitable for the technical field of prefabricated concrete buildings, and is especially suitable for the assembly between the prefabricated main beam and the secondary beam. The structure of the specific embodiment is as follows Figure 1 to Figure 3 As shown, the concrete main beam 1 and the shock-absorbing support device 2 connected with the concrete main beam 1 are included. The bottom of the concrete main beam 1 is fixedly connected with horizontal out-reinforced steel bars 3, and the horizontal out-reinforced steel bars 3 are embedded in the concrete main girder 1 according to a preset position. The horizontal out-reinforced steel bar 3 is detachably connected with the shock-absorbing support device 2.

[0023] The shock-absorbing support device 2 includes a base 14, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com