Plant fiber and cement enhanced light thermal insulation raw soil material

A plant fiber, thermal insulation technology, which is applied in the field of construction engineering to achieve the effects of reducing the size of structural components, light weight, and promoting energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

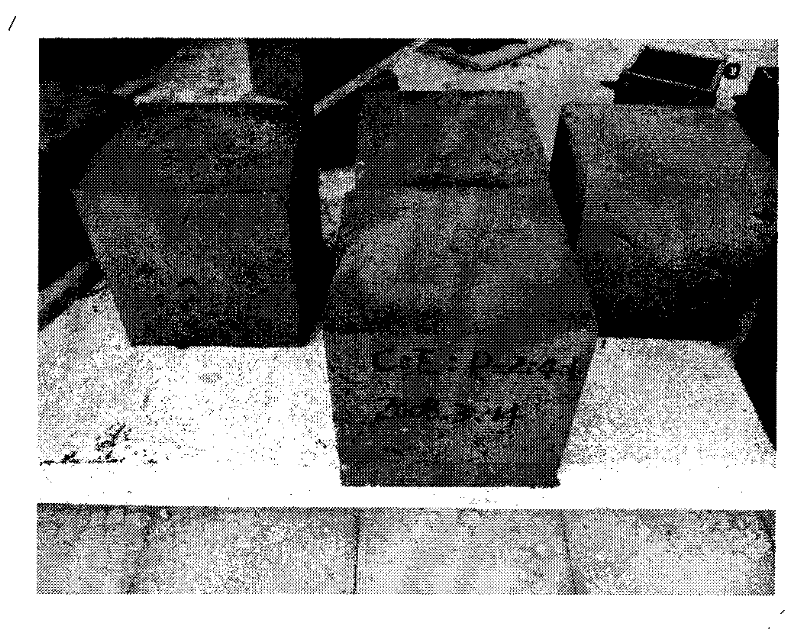

[0038] Example 1: Production of light heat-preservation and heat-insulation raw earth materials reinforced by high-strength plant fibers and cement

[0039] 1. Use a feed crusher to crush plant or crop straw into plant fibers for later use;

[0040] 2. Formulate the mix ratio of plant fiber and cement-reinforced lightweight thermal insulation raw soil material as shown in the following table:

[0041]

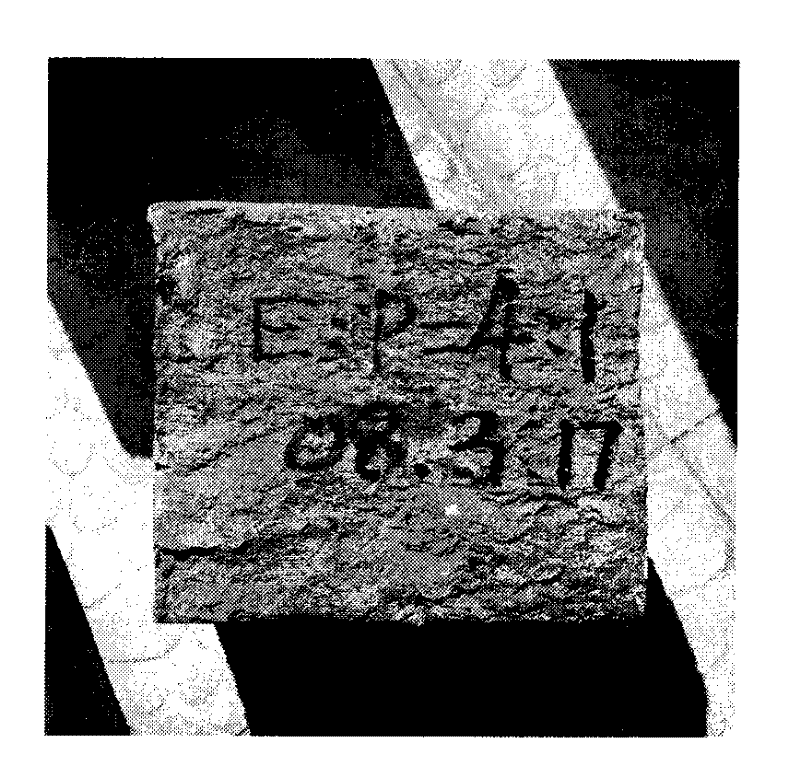

[0042] C represents cement, E represents raw soil, and P represents plant fiber; the ratio in the table is the weight ratio of dry materials.

[0043] 3. Prepare materials according to the weight ratio of materials;

[0044] 4. Put the fire retardant and preservative in the container and stir well until they are completely melted, and set aside;

[0045] 5. Put the raw soil, fiber and cement into the mortar mixer, pour in the dissolved fireproofing agent and preservative, add water and stir;

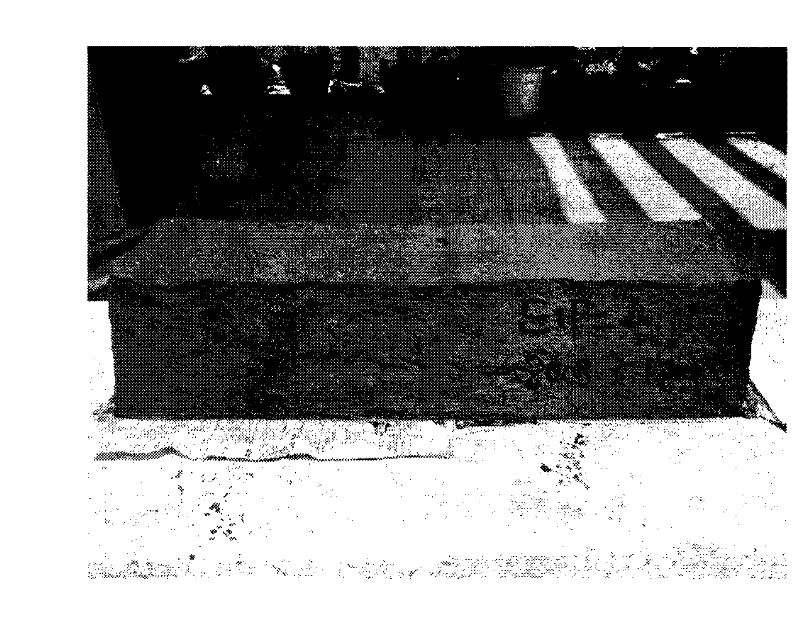

[0046] 6. After stirring evenly (the time is not less than 10 minutes), pour th...

Embodiment 2

[0048] Example 2: Production of low-strength plant fiber and cement-reinforced lightweight thermal insulation raw earth material

[0049] 1. Use a feed crusher to crush plant or crop straw into plant fibers for later use;

[0050] 2. Formulate the mix ratio of low-strength plant fiber and cement-reinforced lightweight thermal insulation raw soil material as shown in the following table:

[0051]

[0052] C represents cement, E represents raw soil, and P represents plant fiber; the ratio in the table is the weight ratio of dry materials.

[0053] 3. The rest of the manufacturing process is the same as in Example 1. The self-weight of blocks made by this method is about 600kg / m 3 , the thermal conductivity is about 0.1W / (m·K), and the thermal insulation ability is stronger. It can be used to build frame-filled walls of energy-saving buildings.

Embodiment 3

[0054] Example 3: Made with only plant fiber-reinforced lightweight heat-preservation and heat-insulation raw earth materials

[0055] When the raw soil where the project is located is very viscous, no cement can be added as a cementing material, and only plant fibers can be used to strengthen the raw soil. This kind of plant fiber-reinforced light-weight thermal insulation raw soil material has better environmental effects and lower cost. The production method is as follows:

[0056] 1. Use a feed crusher to crush plant or crop straw into plant fibers for later use;

[0057] 2. Formulate the common mix ratio of plant fiber-reinforced lightweight thermal insulation raw soil materials as shown in the following table:

[0058]

[0059] E represents raw soil, P represents plant fiber; the ratio in the table is the weight ratio of dry material.

[0060] 3. Before the weight of the raw soil is weighed, a simple moisture content test is required, and the weight of the raw soil ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com