Single-sided prefabricated concrete steel wire net rack insulation board wall and construction method thereof

A technology of prefabricated concrete and steel wire grid, applied in the direction of building insulation materials, walls, structural elements, etc., can solve the problems of inconvenient wall construction, difficult quality control in the construction process, inconvenient connection operation, etc., and achieve the goal of improving structural strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

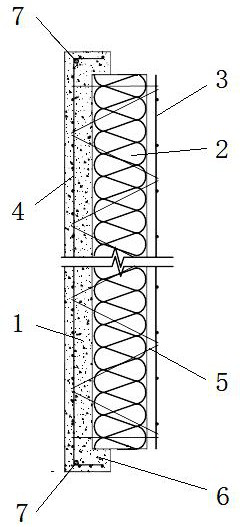

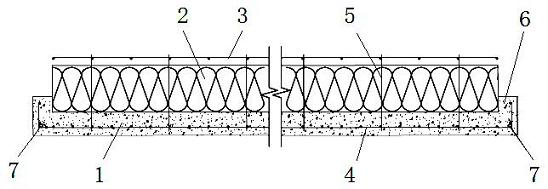

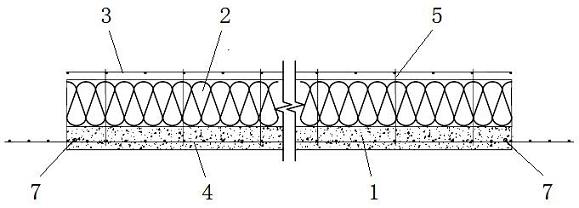

[0034] The invention discloses a single-sided prefabricated concrete steel wire grid insulation board wall (may be referred to as the wall), such as Figure 5 As shown, the wall includes a single-sided prefabricated concrete steel wire grid insulation board and a cast-in-place concrete inner leaf wall 8 integrated. like Figure 1-4 As shown, the single-sided prefabricated concrete steel wire grid insulation board includes a steel wire grid sandwich insulation board and a prefabricated concrete outer leaf wall 1 . Wherein the prefabricated concrete outer leaf wall 1 is cast in the factory. The steel wire grid sandwich insulation board includes an insulation material layer 2, an inner steel wire mesh 3 and an outer steel wire mesh 4 that are respectively located on the inner and outer sides of the insulation material layer and are spaced apart from the insulation material layer, and several wear-through Insert wires 5 that pass through the heat-insulating material layer and ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com