Method for realizing butt joint of steel pipes by aid of axial cross plug board and butt joint part

A technology of butt fittings and steel pipes, which is applied in construction, building construction, etc., can solve problems such as the size of the connection parts of fire hazards, and achieve the effects of easy control of connection quality, convenient construction, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: The method and steps for butt jointing of two steel pipes with elliptical cross-sections with an axial cross plate.

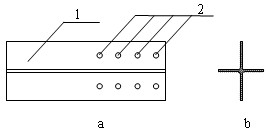

[0028] 1. If figure 1 a. figure 1 As shown in b, one end of each steel plate on the cross plate 1 is processed with several plate holes 2 for connecting high-strength bolts;

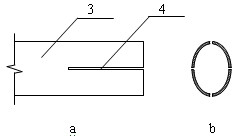

[0029] 2. If figure 2 a. figure 2 As shown in b, the butt end of the first steel pipe 3 is cut and processed to form a cross groove 4, the width of which is equivalent to the thickness of the cross plate 1, and can accommodate the insertion of the cross plate 1 along the axial direction of the steel pipe 3;

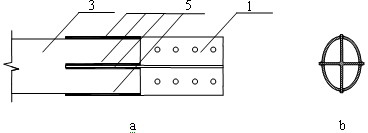

[0030] 3. If image 3 a. image 3 As shown in b, after one end of the unprocessed round hole 2 of the cross plate 1 is inserted into the end of the first steel pipe 3 with the cross groove 4, welding is performed at the joint between the cross plate 1 and the first steel pipe 3 to form a weld seam 5;

[0031] 4. The connection method and steps of the sec...

Embodiment 2

[0034] Embodiment 2: A method and steps for butt jointing of three or more steel pipes with elliptical cross-sections using an axial cross plate.

[0035] 1. If figure 1 a. figure 1 As shown in b, one end of each steel plate on the cross plate 1 is processed with several plate holes 2 for connecting high-strength bolts;

[0036] 2. If figure 2 a. figure 2 As shown in b, the butt end of the steel pipe 3 is cut and processed to form a cross groove 4, the width of which is equivalent to the thickness of the cross plate 1, and can accommodate the insertion of the cross plate 1 along the axial direction of the steel pipe 3;

[0037] 3. If image 3 a. image 3 As shown in b, after one end of the unprocessed round hole 2 of the cross plate 1 is inserted into the end of the first steel pipe 3 provided with the cross groove 4, welding is performed at the joint between the cross plate 1 and the first steel pipe steel pipe 3 to form a weld. seam 5;

[0038] 4. The connection met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com