Construction method of prefabricated assembly of concrete sill

A technology of prefabricated assembly and construction method, applied in the direction of formwork/formwork/work frame, on-site preparation of building components, connection of formwork/formwork/work frame, etc., can solve the problem of waterproof effect and construction quality and efficiency. Taking into account and other issues, to avoid water seepage problems, improve construction efficiency, and ensure the effect of the joint surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

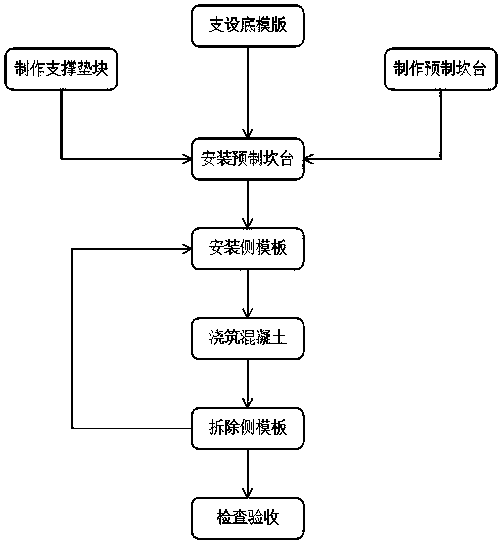

[0050] Embodiment: A kind of concrete sill prefabricated assembly construction method, see figure 1 , including the following steps:

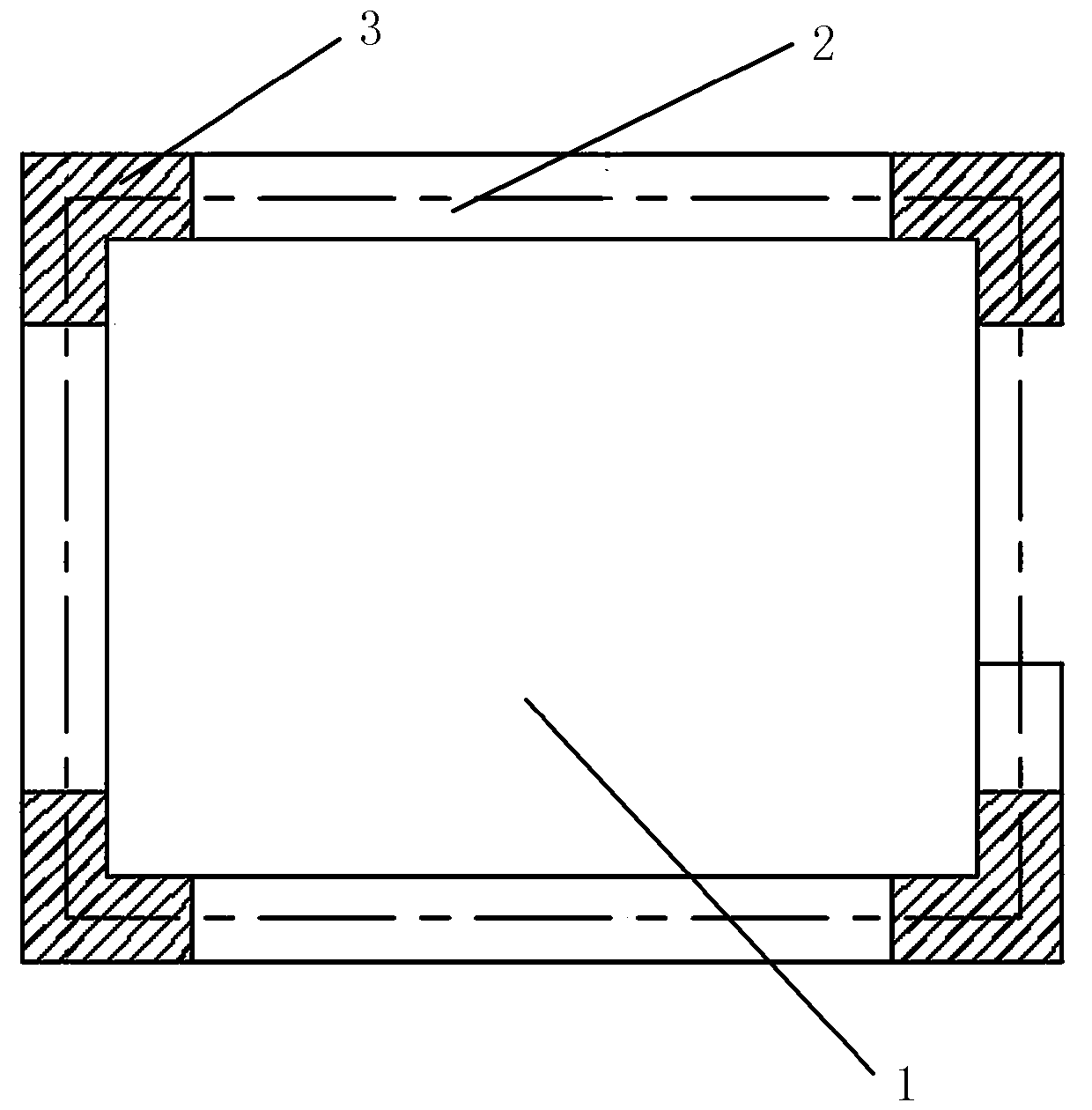

[0051] In this embodiment, the construction toilet such as figure 2 As shown, the prefabricated sill 2 is poured at the surrounding walls of the descending plate 1 of the toilet. The design thickness of the surrounding walls is 200mm, and the corner cast-in-place section 3 is set at the vertical junction of adjacent walls. Usually, the corner cast-in-place section 3 is used for Construction of structural columns.

[0052] 1) Support the bottom formwork.

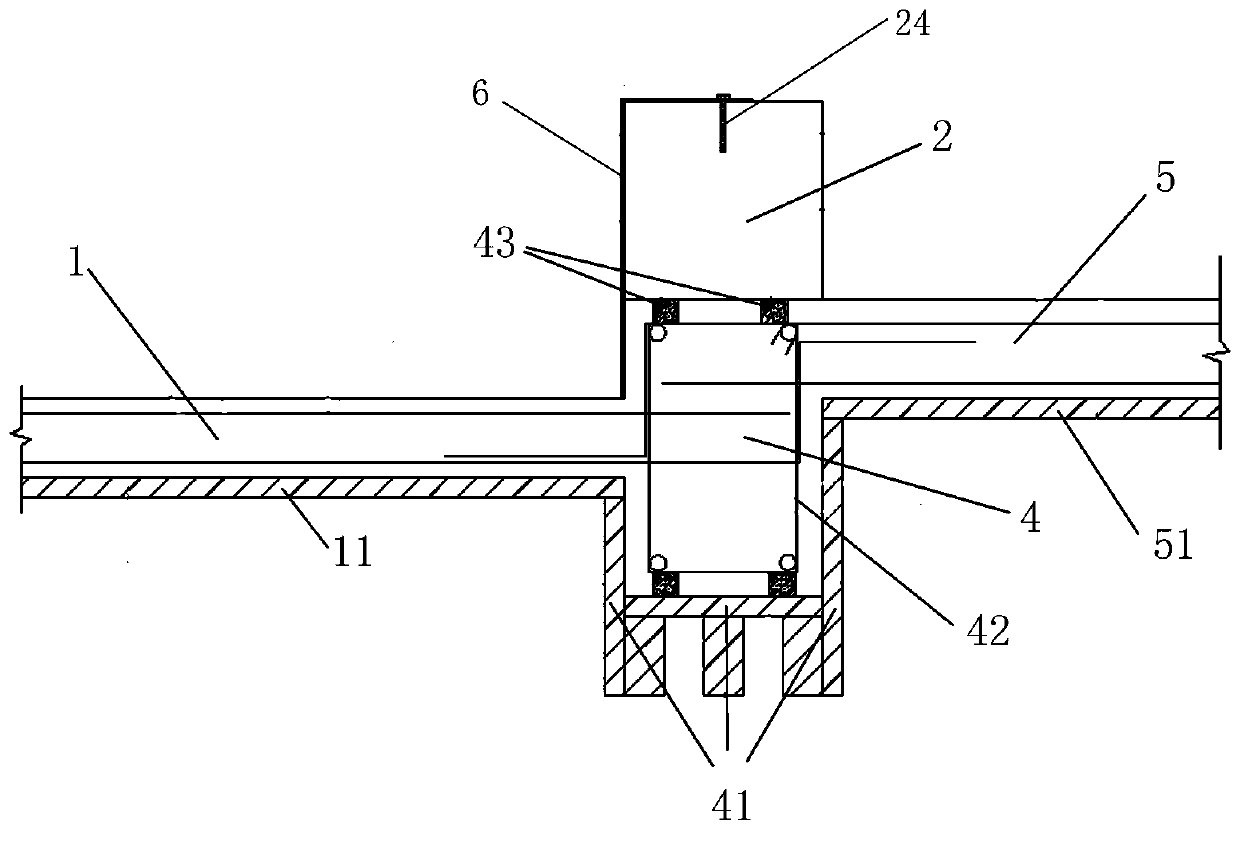

[0053] First of all, the beam slab formwork, floor formwork support and steel bar binding around the toilet must be completed. This step adopts conventional construction methods, and the relative positions of each part are as follows: image 3 As shown, wherein the bottom formwork 11 of the lowering plate is located at the toilet side, the beam plate formwork 41 is supported on the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com