Four-degree-of-freedom magnetic suspension rotating cylinder

A technology of magnetic levitation and degree of freedom, applied to magnetic bearings, bearings, shafts and bearings, etc., can solve the problems of high machining accuracy and installation accuracy, difficulty in drum design, installation and debugging, and inflexible position adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

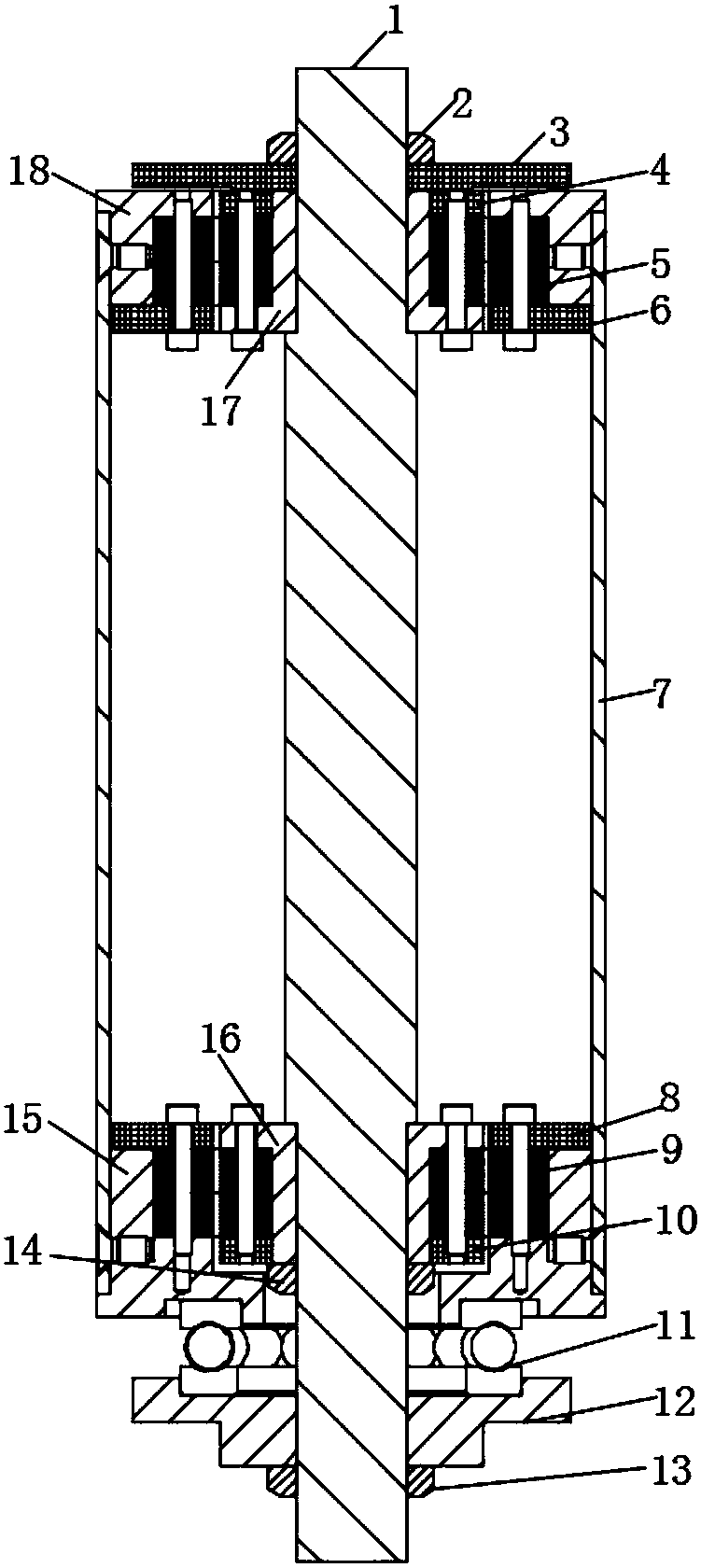

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

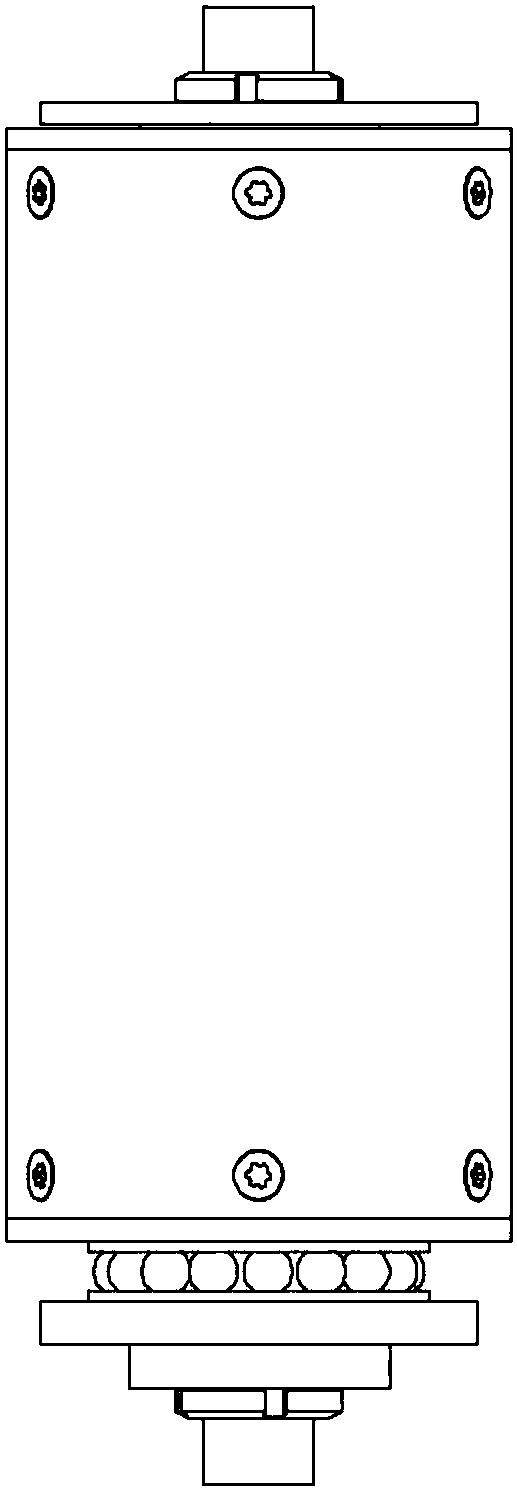

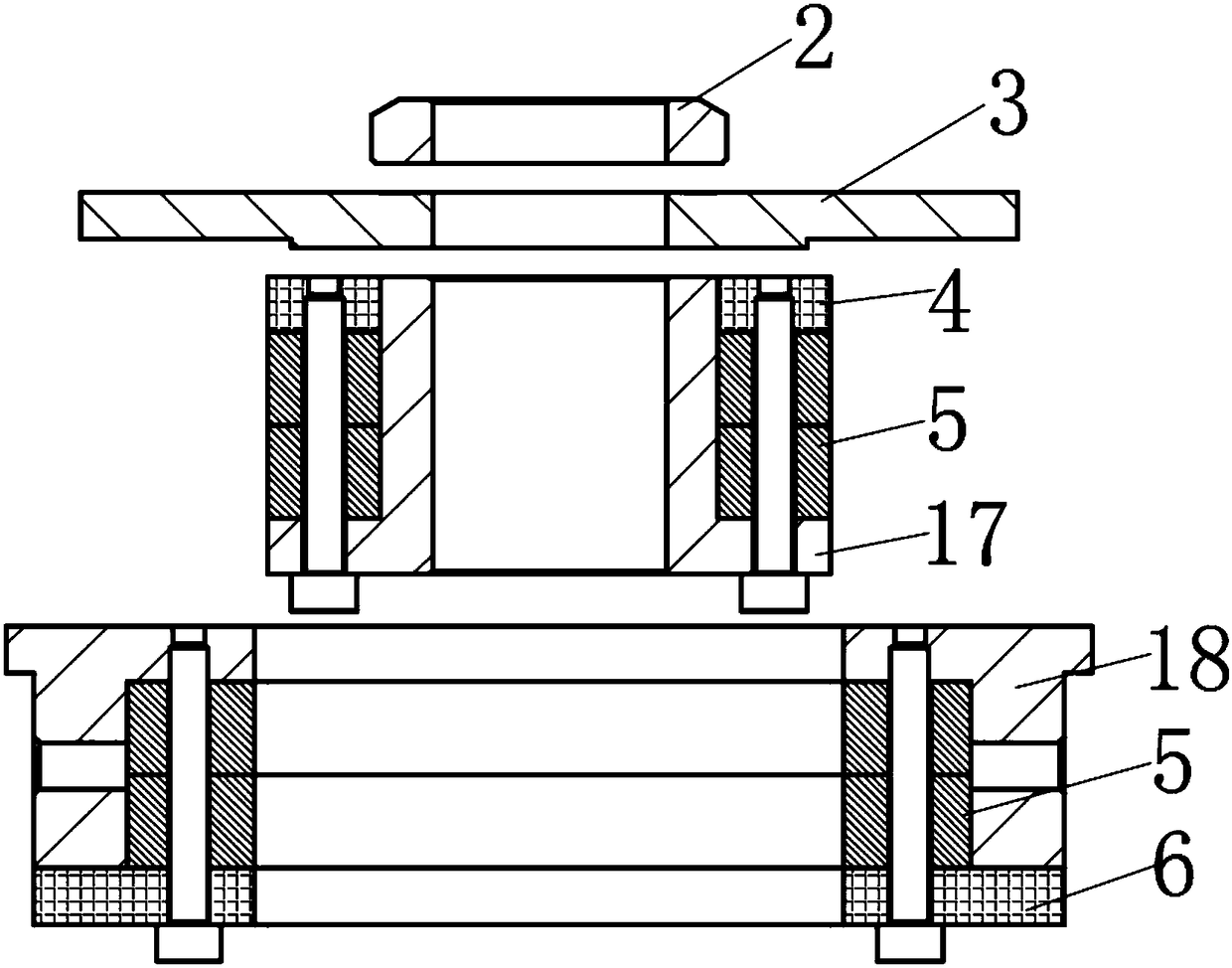

[0030] refer to Figure 1-6 As shown, the four-degree-of-freedom magnetic levitation drum of this embodiment includes a threaded shaft 1, an upper permanent magnetic radial bearing 5, a lower permanent magnetic radial bearing 6, a bearing adapter, an outer drum 7, and a translational thrust bearing 11 , Tray 12, lock nuts, bolts.

[0031] The upper and lower ends of the threaded shaft 1 are provided with fine threads, the thread lead angle of the threaded shaft 1 is smaller than the equivalent friction angle, the middle is an optical axis, and the diameter of the optical axis is greater than the outer diameter of the thread to form a shaft shoulder. The threaded shaft 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com