Overflow valve system for railway locomotive

A railway locomotive and overflow valve technology, which is applied in the field of overflow valve system, can solve problems such as deformation of duckbill valve, and achieve the effects of reducing air pressure cross-flow, preventing water backflow, and preventing sewage and odor from being sprayed back.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

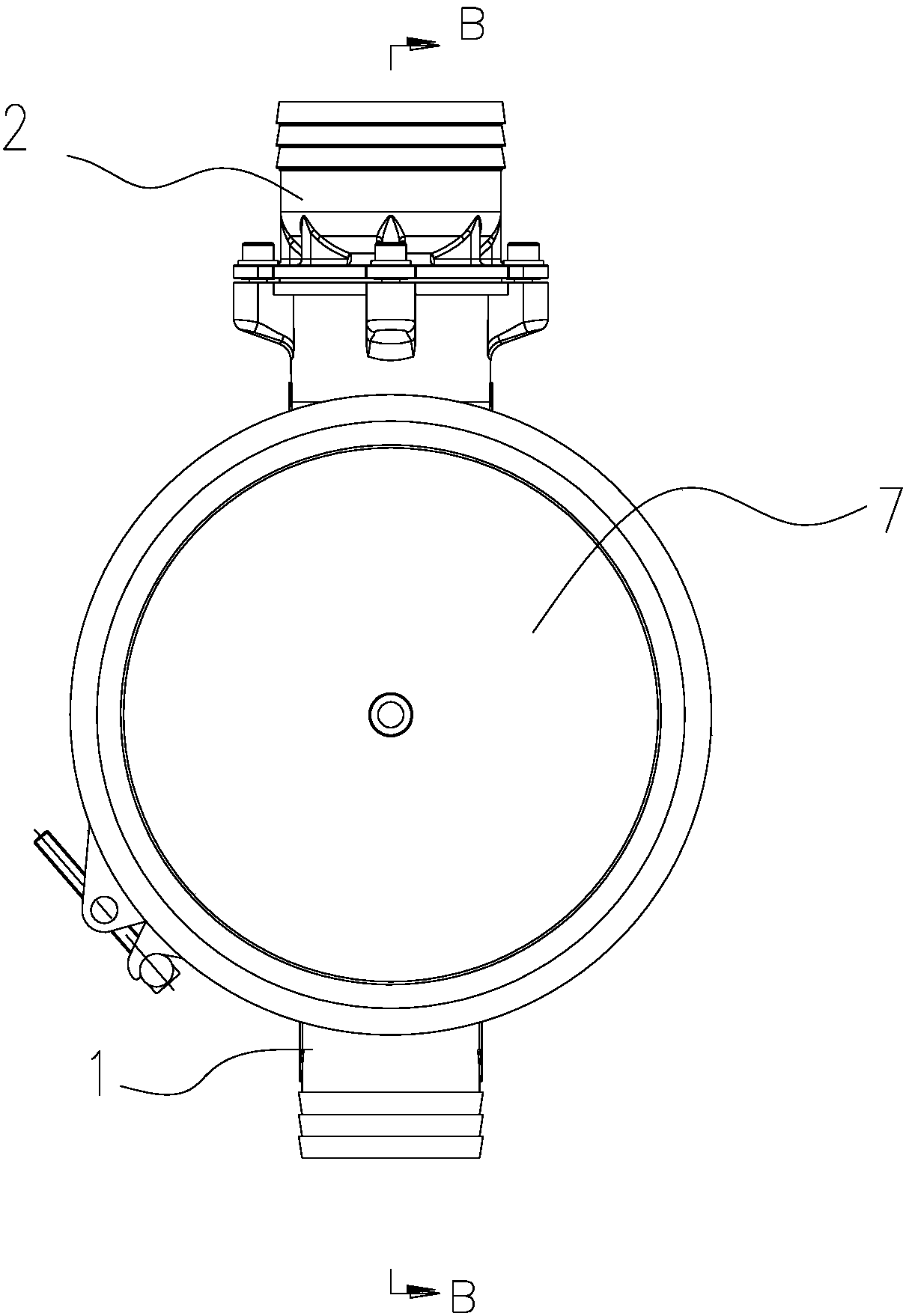

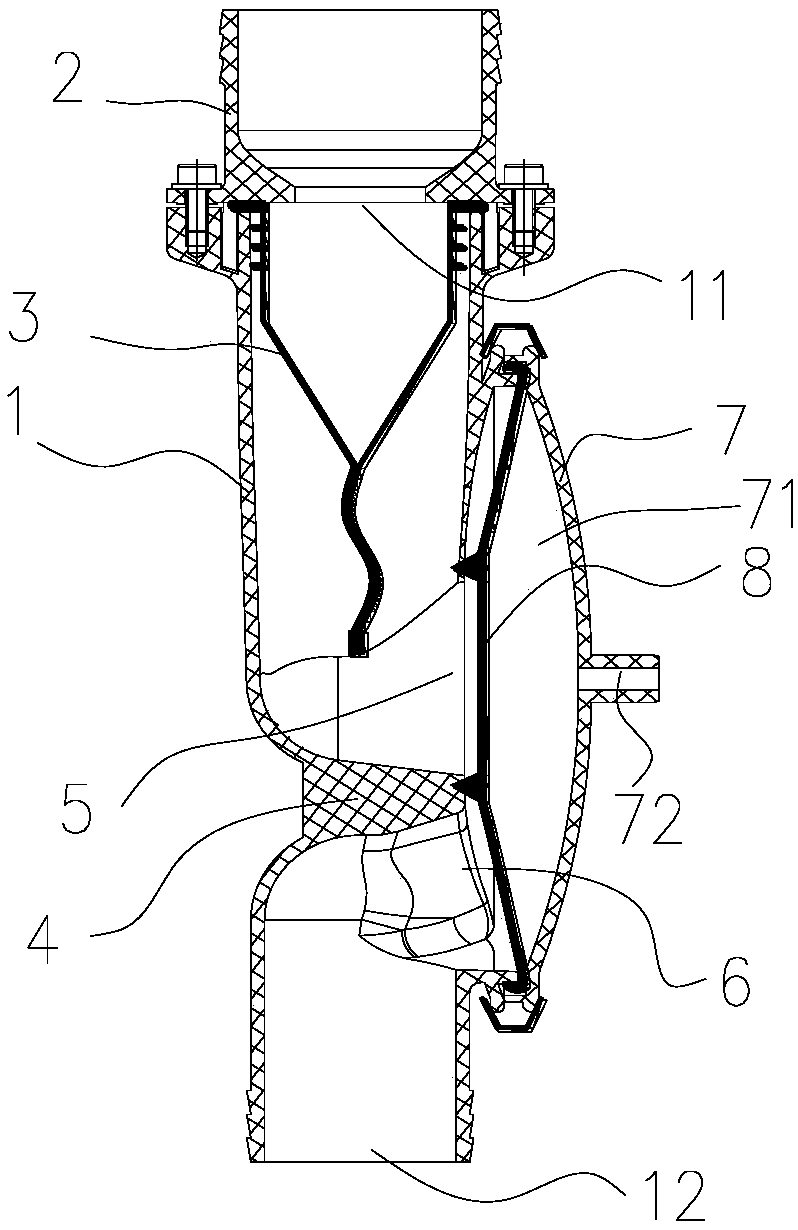

[0031] Such as Figure 1-2 , The pipe 1 is a straight pipe, and the second overflow valve body 7 is located on one side of the straight pipe.

Embodiment 2

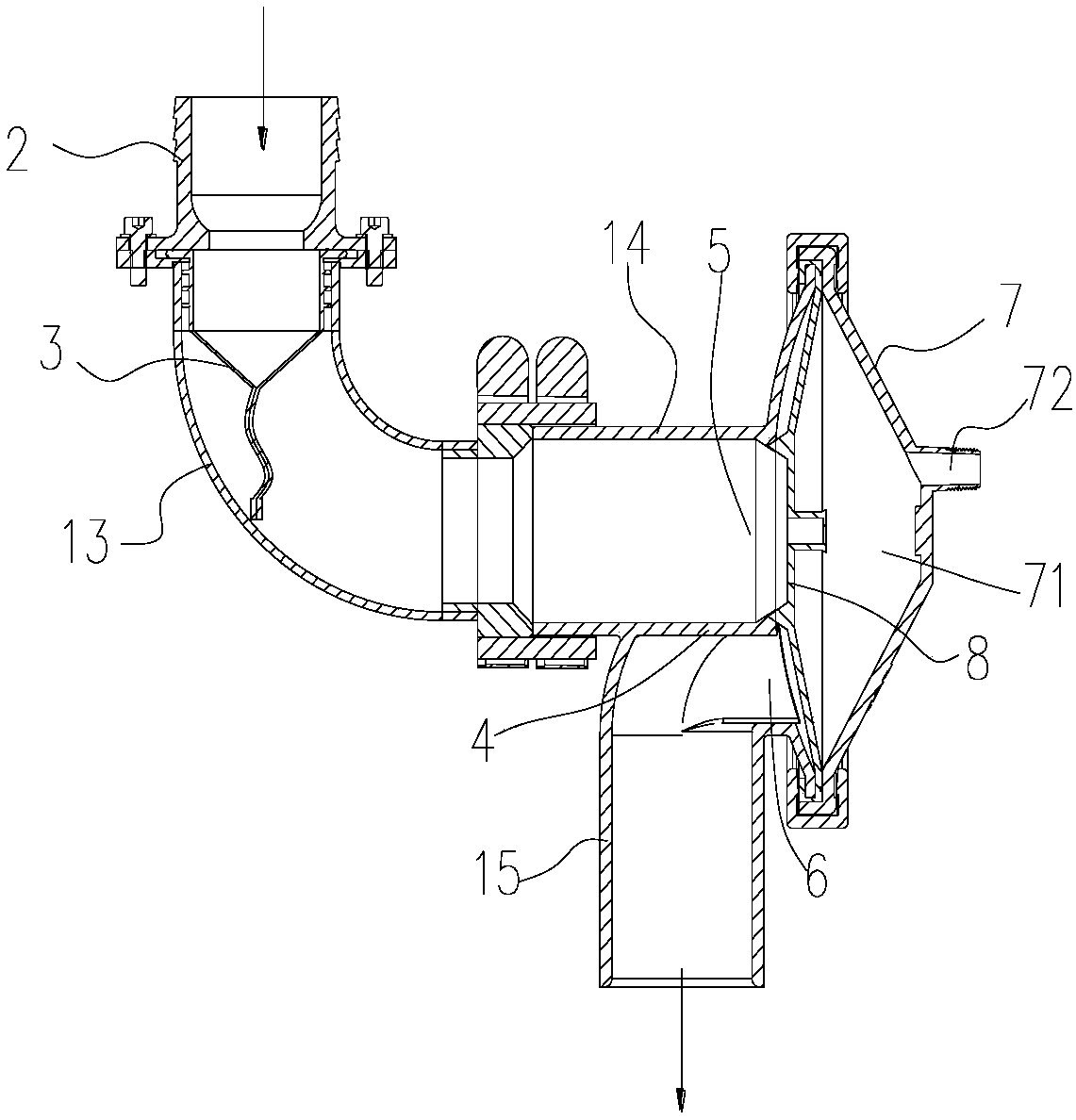

[0033] Such as image 3 , The pipeline 1 is an elbow, and the elbow includes an inlet elbow 13, a horizontal pipe 14 and a vertical pipe 15 in sequence along the water flow direction. The second overflow valve body 7 is located at the end of the horizontal pipe 14, and the water outlet 12 of the horizontal pipe 14 It is the first opening 5, the bottom end side wall of the horizontal tube 14 is a stop 4, and the second opening 6 is opened on the side wall of the vertical tube 15.

[0034] Specifically, the use of the relief valve system of the present invention in a locomotive has the following embodiments:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com