A full-water-cooled column head and a full-water-cooling method thereof

A fully water-cooled, stigma-capable technology, applied in the direction of furnace cooling, electric furnace heating, furnace, etc., can solve the problem that the cover body cannot be cooled by cooling water, and achieve the effects of avoiding the risk of explosion, avoiding blockage, and preventing local static

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with specific embodiments.

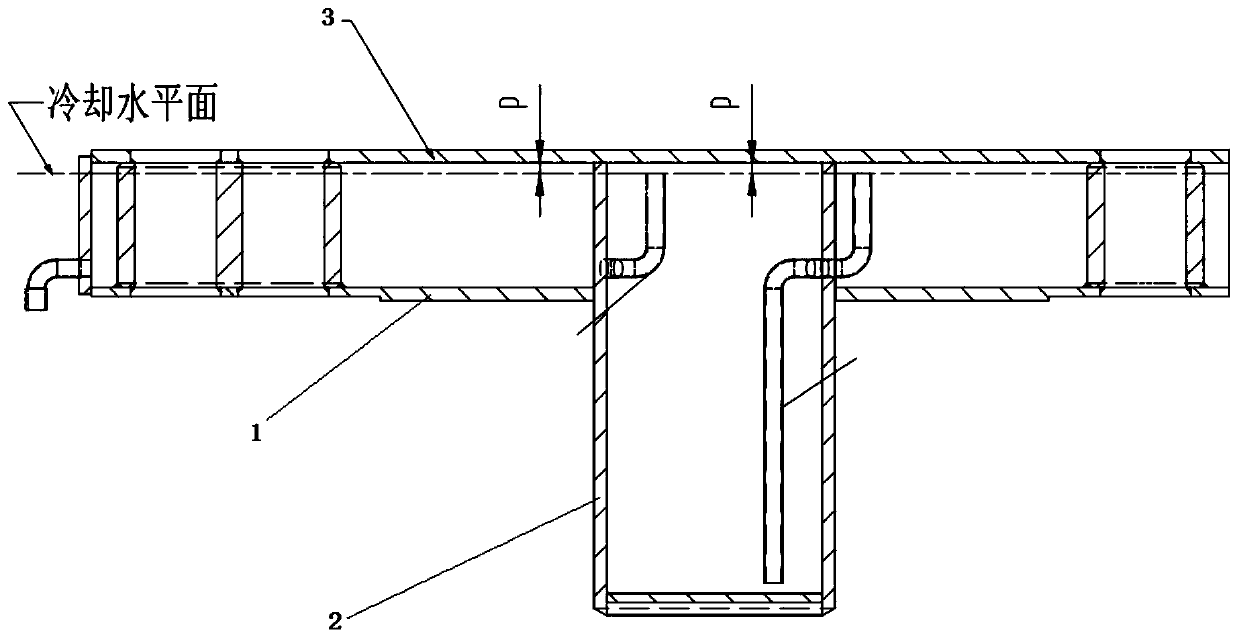

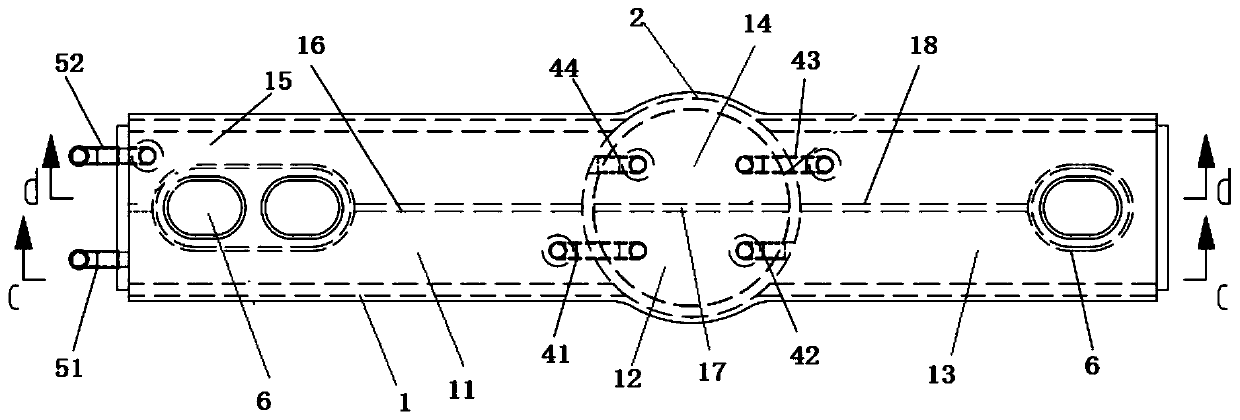

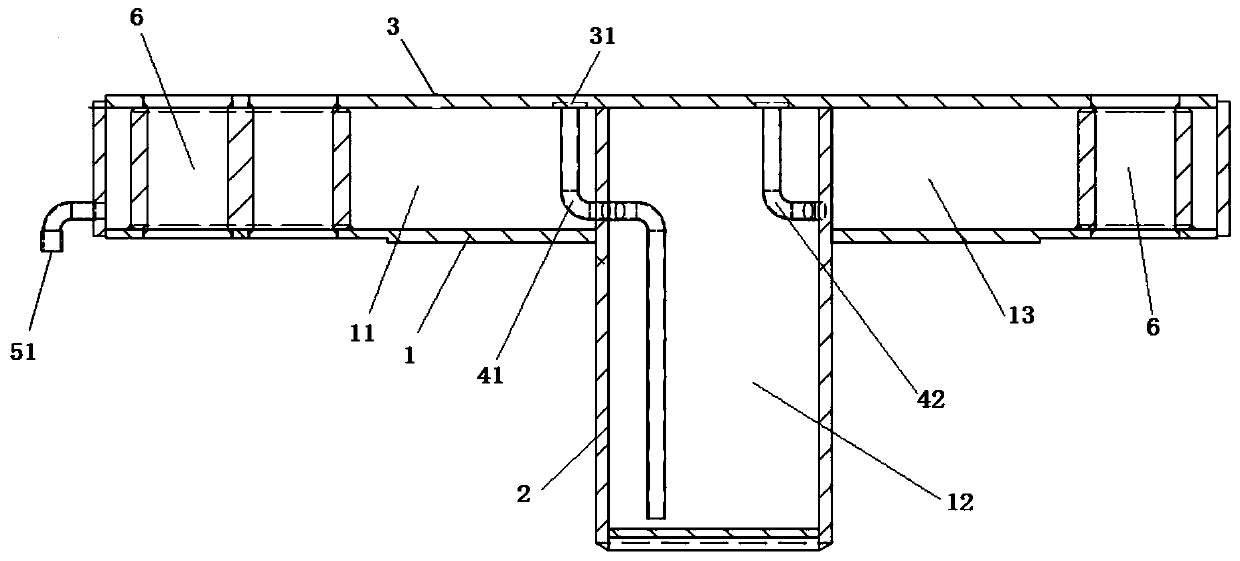

[0039] Such as Figure 2-4As shown, a full water-cooled column head includes a column 2 and a box body 1 with an open upper end, and a cover body 3 sealingly connected with it is provided at the open upper end of the box body 1; the column 2 is one end A blind tube with one end closed, one end of the blind tube opening extends into the box body 1 from the bottom of the box body 1, and one end of the blind tube opening is flush with the lower bottom surface of the cover body 3; The box body 1 is in the shape of a cuboid, and the outer diameter of the blind pipe is not less than the width of the box body 1, so as to divide the box body 1 into three mutually isolated first cavities, second cavities and third cavities. Cavities, the three are arranged in a linear manner; the lower part of the first cavity is connected with a water inlet pipe 51, and the upper part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com