Rotation control component and novel manual service switch

A technology for manual maintenance of switches and control components, applied to electrical components, circuits, emergency protection devices, etc., can solve the problems of scrapped manual maintenance switches, non-removable fuses, complex and cumbersome operations, etc., to achieve beautiful appearance and avoid heat The effect of being damaged, flexible and convenient to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

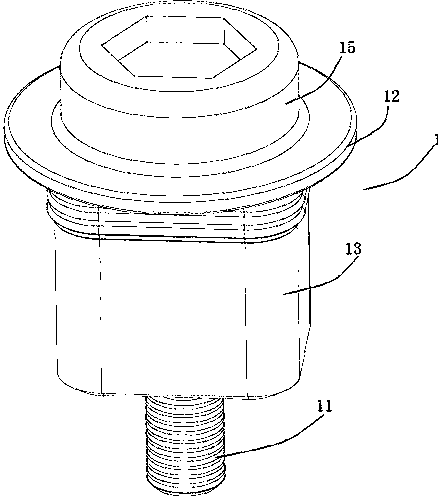

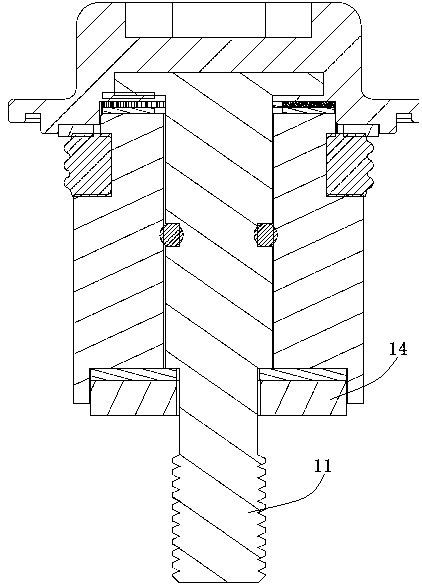

Embodiment 1

[0030] This embodiment discloses a rotary control component, which realizes the connection or disconnection with the external circuit through the rotation, and can be applied to the MSD manual maintenance switch. On the premise that the fuse is not blown, the MSD manual maintenance switch does not need It can be disconnected from the external circuit by removing the fuse, such as figure 1 and figure 2 As shown, the rotation control component 1 includes a connected screw 11, a cover body 12, a rotating cylinder 13 and a copper conducting block 14, wherein the cover body 12 is arranged on the surface of the screw entry end of the rotating cylinder 13; the copper conducting block 14 directly Or indirectly connected to the external circuit, the indirect connection refers to the connection of the copper conducting block 14 with other conductors connected to the external circuit.

[0031] The head of the screw 11 is provided with a knob 15, and the inner wall of the rotating cylin...

Embodiment 2

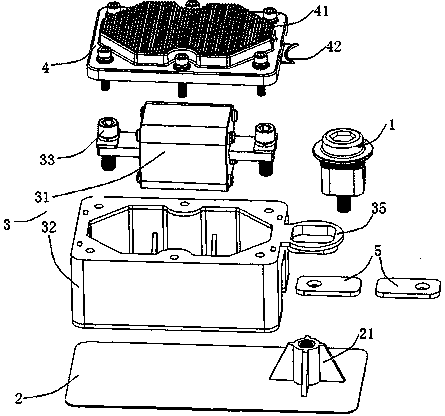

[0034] This embodiment discloses a new type of MSD manual maintenance switch. The manual maintenance switch has the advantages of simple structure, convenient operation and beautiful appearance. Working mode, that is: when the overload or short-circuit current passes through the fuse, heat will be generated and blown, thereby disconnecting the circuit; if the fuse is not blown, and the circuit needs to be repaired in response to an emergency, it can only be done by disassembling the fuse. To achieve the purpose of breaking the circuit. The MSD manual maintenance switch of this embodiment is used in combination with the rotary control part of Embodiment 1. When the fuse is not blown, the external source circuit is mechanically disconnected or connected through the rotary control part, thereby protecting the safety of the high-voltage system and maintenance personnel. Flexible and easy.

[0035] like image 3As shown, the MSD manual maintenance switch of this embodiment includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com