A surface modification method for suppressing the diffusion of conductive silver glue on the surface of the packaging substrate pad

A technology of conductive silver glue and packaging substrate, which is applied to the formation of conductive patterns, circuits, electrical components, etc., can solve problems such as abnormal wire bonding of conductive silver glue, and achieve the effect of realizing electrical connection and inhibiting diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

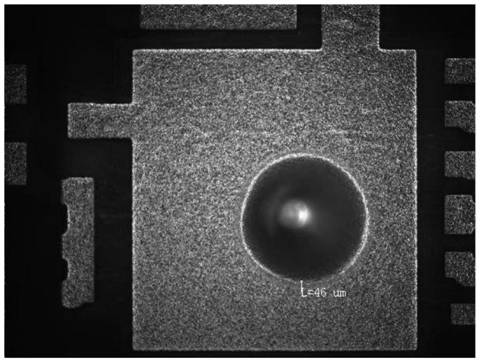

[0028] Step 1: Put the packaging substrate containing copper pads into the degreasing tank for degreasing treatment to remove oil stains such as oxides on the copper surface and finger marks. The degreasing time is 5 minutes, and the degreasing temperature is 50°C. After degreasing, use Ionized water cleaning; then put the substrate into the microetching solution system containing 5-aminotetrazole 3wt%, sulfuric acid 10wt%, hydrogen peroxide 8wt%, and carry out the planarity microetching of the copper pad, and the planarity microetching solution is carried out The temperature of the treatment is 25°C, the treatment time is 90s, and after the completion, it is cleaned with deionized water; at this time, a scanning electron microscope is used to observe the copper surface obtained after the pad is processed by the planar microetching system, and the results are as follows image 3 shown;

[0029] Step 2: Put the micro-etched substrate into the activation cylinder for ionic palla...

Embodiment 2

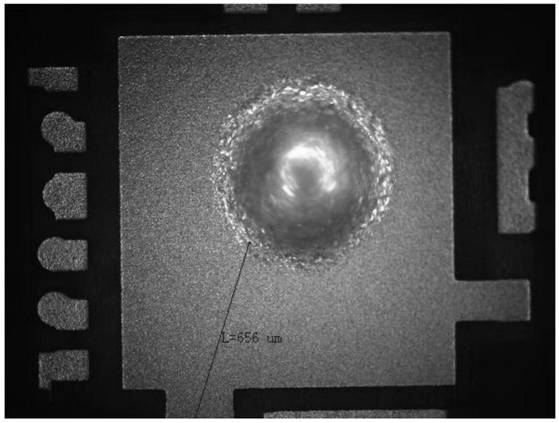

[0051] Step 1: Put the packaging substrate containing copper pads into the degreasing tank for degreasing treatment to remove oil stains such as oxides on the copper surface and finger marks. The degreasing time is 5 minutes, and the degreasing temperature is 50°C. After degreasing, use Ionized water cleaning; then put the substrate into the microetching solution system containing 2-methyl-5-aminotetrazole 2wt%, sulfuric acid 18wt%, hydrogen peroxide 10wt%, and carry out the planarity microetching of the copper pad, smooth The temperature of the microetching solution is 25°C, the treatment time is 90s, and it is cleaned with deionized water after completion;

[0052] Step 2: Put the microetched substrate into the activation cylinder for ionic palladium activation treatment, the activation time is 100s, the activation temperature is 30°C, and after activation, it is cleaned with deionized water; the activated substrate is placed in the nickel cylinder, Electroless nickel, palla...

Embodiment 3

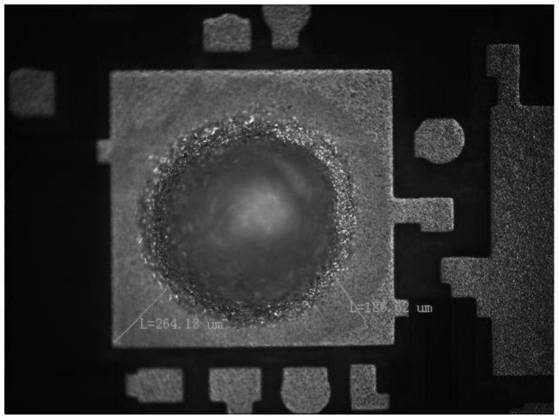

[0057] Step 1: Put the packaging substrate containing copper pads into the degreasing tank for degreasing treatment to remove oil stains such as oxides on the copper surface and finger marks. The degreasing time is 5 minutes, and the degreasing temperature is 50°C. After degreasing, use Ionized water cleaning; then put the substrate into the microetching solution system containing 5-aminotetrazole 2wt%, 2-methyl-5-aminotetrazole 2wt%, sulfuric acid 6wt%, hydrogen peroxide 12wt%, and carry out copper The flatness micro-etching of the pad, the temperature of the flatness micro-etching solution is 25°C, the processing time is 90s, and it is cleaned with deionized water after completion;

[0058] Step 2: Put the micro-etched substrate into the activation cylinder for ionic palladium activation treatment, the activation time is 200s, the activation temperature is 15°C, and after activation, clean it with deionized water; put the activated substrate into the nickel cylinder, Electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com