Corrosion-resistant flexible graphite down lead and preparation method thereof

A flexible graphite and down-conductor technology, applied in the down-conductor field, can solve the problems of poor electrical connection between metal and graphite, affecting the function of the down-conductor leakage channel, etc., to reduce the surface area of the anode, ensure effective electrical connection, Increase the effect of anodic polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

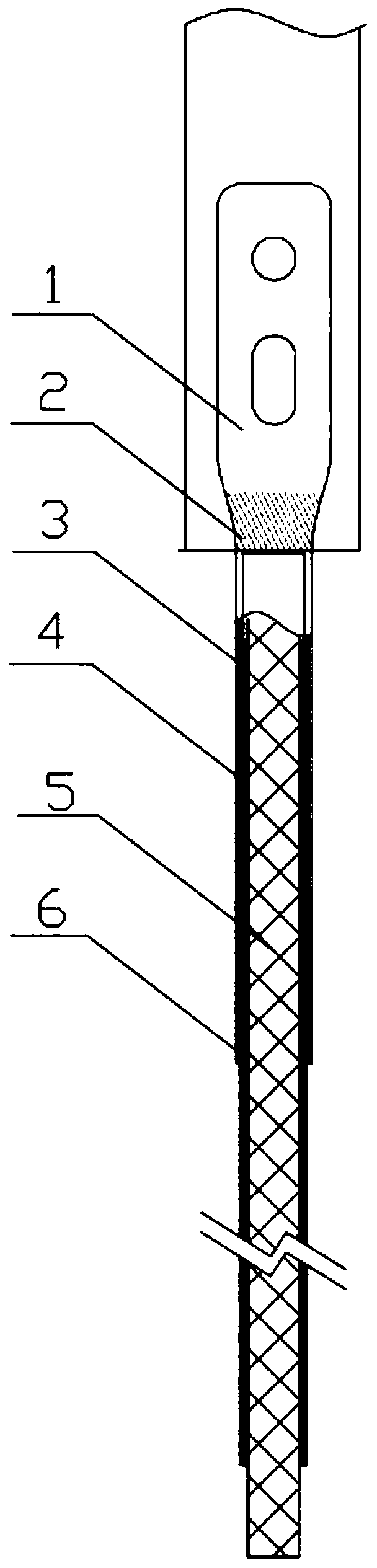

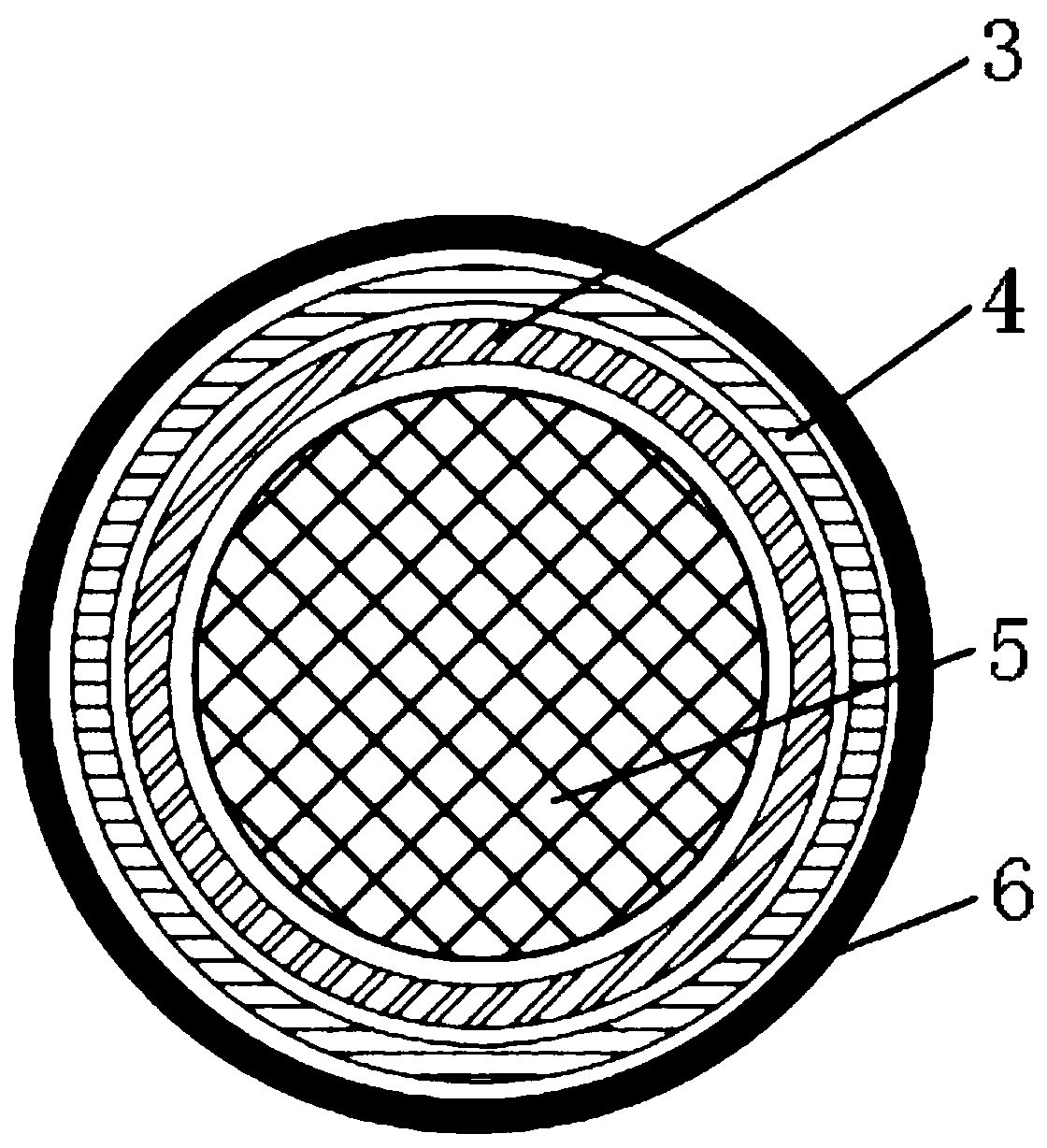

[0037] Example 1, such as Figure 1-3 shown;

[0038] A corrosion-resistant flexible graphite downconductor, characterized in that it includes:

[0039] Stainless steel connector 1; there is a hole inside the stainless steel connector 1, the first end of the stainless steel connector 1 is electrically connected to the protected equipment, the first end of the stainless steel connector 1 is closed, and the opening of the hole faces the first end of the stainless steel connector 1 Two ends;

[0040] Flexible graphite body 5; the flexible graphite body 5 is placed in the hole of the stainless steel connector 1, and the first end of the flexible graphite body 5 is electrically connected to the stainless steel connector 1; the second end of the flexible graphite body 5 extends out of the stainless steel connector 1 setting;

[0041] heat-shrinkable insulating sleeve 3; the heat-shrinkable insulating sleeve 3 is coated on the outer wall of the flexible graphite body 5;

[0042] ...

Embodiment 2

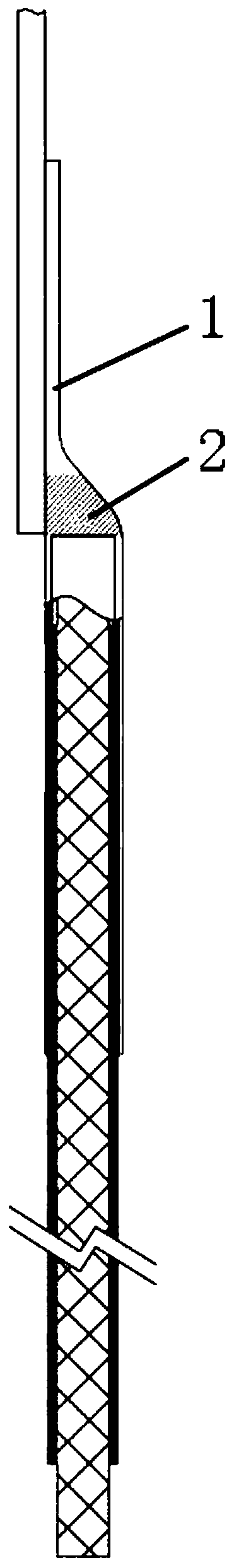

[0043] Example 2, such as figure 1 , 2 shown;

[0044] The difference between this embodiment and Embodiment 1 is that: the stainless steel connecting piece 1 is formed into a tubular structure, and the inside of the first end of the stainless steel connecting piece 1 is sealed by a sealant 2 .

[0045] In this embodiment, the stainless steel connector 1 can be understood as a semi-sealed structure; the premise of localized corrosion is the presence of a corrosive medium, and the layout of this structure can effectively prevent or delay the corrosive medium in the atmosphere from entering the metal-graphite interface;

Embodiment 3

[0047] The difference between this embodiment and embodiment 2 is that the sealant 2 is a silicone sealant, an acrylic rubber sealant or a polyurethane sealant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com