In-place-packaged integrated circuit support structure and manufacturing method thereof

A support structure and integrated circuit technology, applied in the direction of circuit, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as detachment, chip and support separation, inclination, etc., to achieve accurate positioning direction, chip end flat, stable welding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

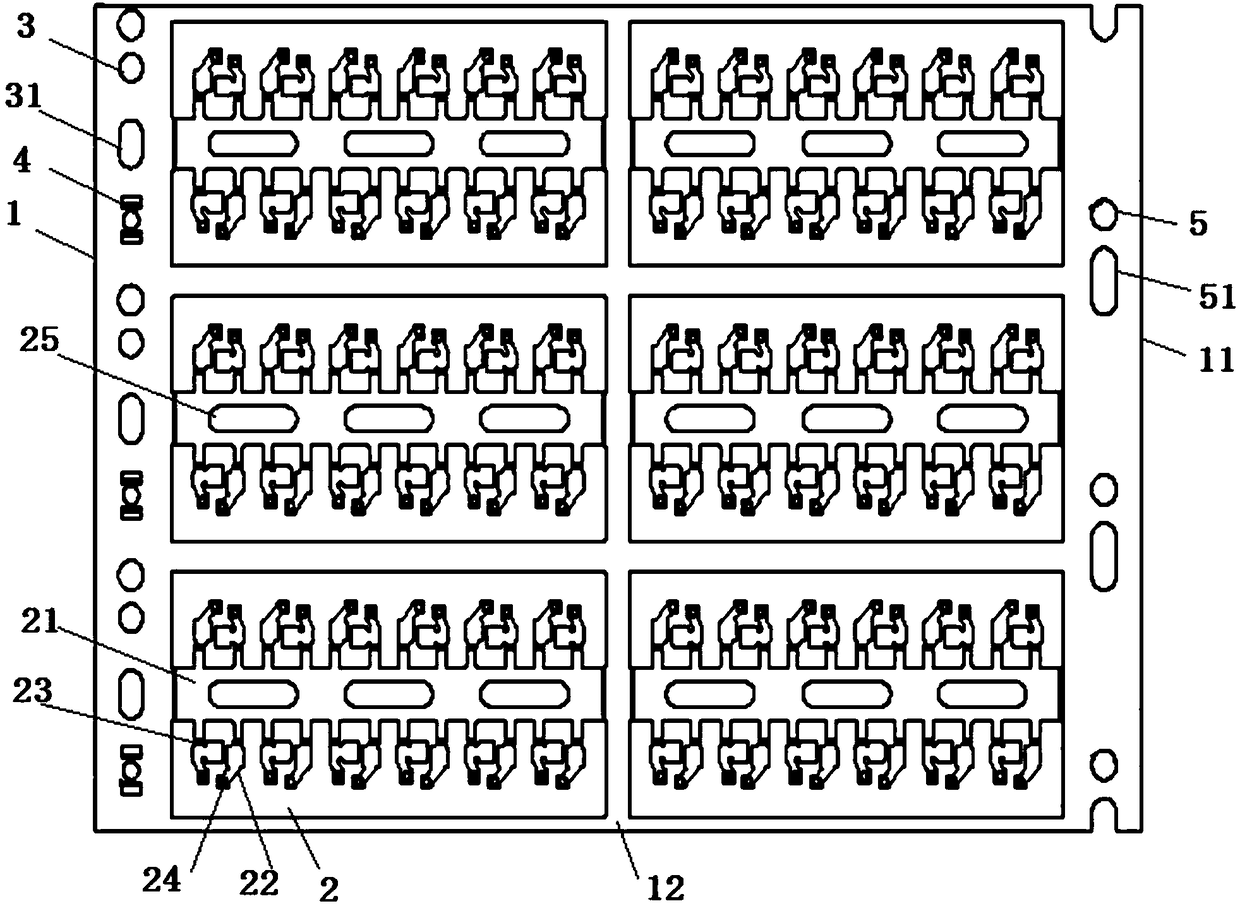

[0025] refer to figure 1 As shown, this embodiment is an integrated circuit support structure packaged in place, including a support body and several groups of PAD regions 2 arranged in the support body;

[0026] The bracket body includes a first bracket 1 and a second bracket 11 arranged in parallel, and the ends of the first bracket 1 and the second bracket 11 are respectively connected to form a frame structure.

[0027] The first bracket 1 and the second bracket 11 are provided with several groups of symmetrically arranged PAD regions 2 , and in this embodiment, there are three groups of PAD regions 2 , and the number of each group is two.

[0028] A connecting frame 12 is arranged between the first bracket 1 and the second bracket 11 , and the connecting frame 12 is arranged parallel to the first bracket 1 ; the two sides of the connecting frame 12 are respectively provided with PAD areas 2 .

[0029] The PAD area 2 includes a connection part 21, several sets of welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com