Heat dissipation device

A technology of a heat sink and heat sink, which is applied in the direction of modification, cooling/ventilation/heating transformation, and electrical components through conduction and heat transfer. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

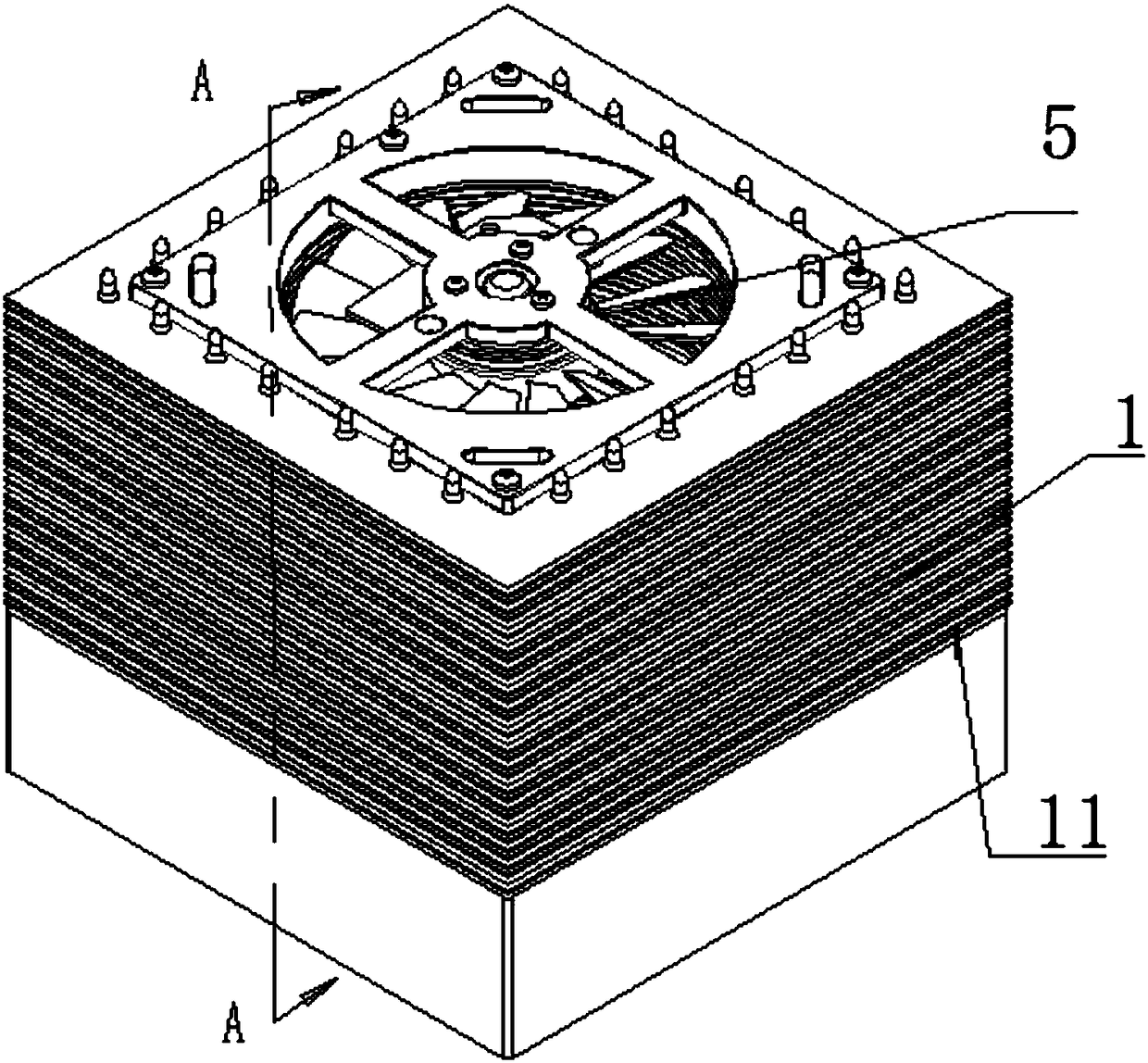

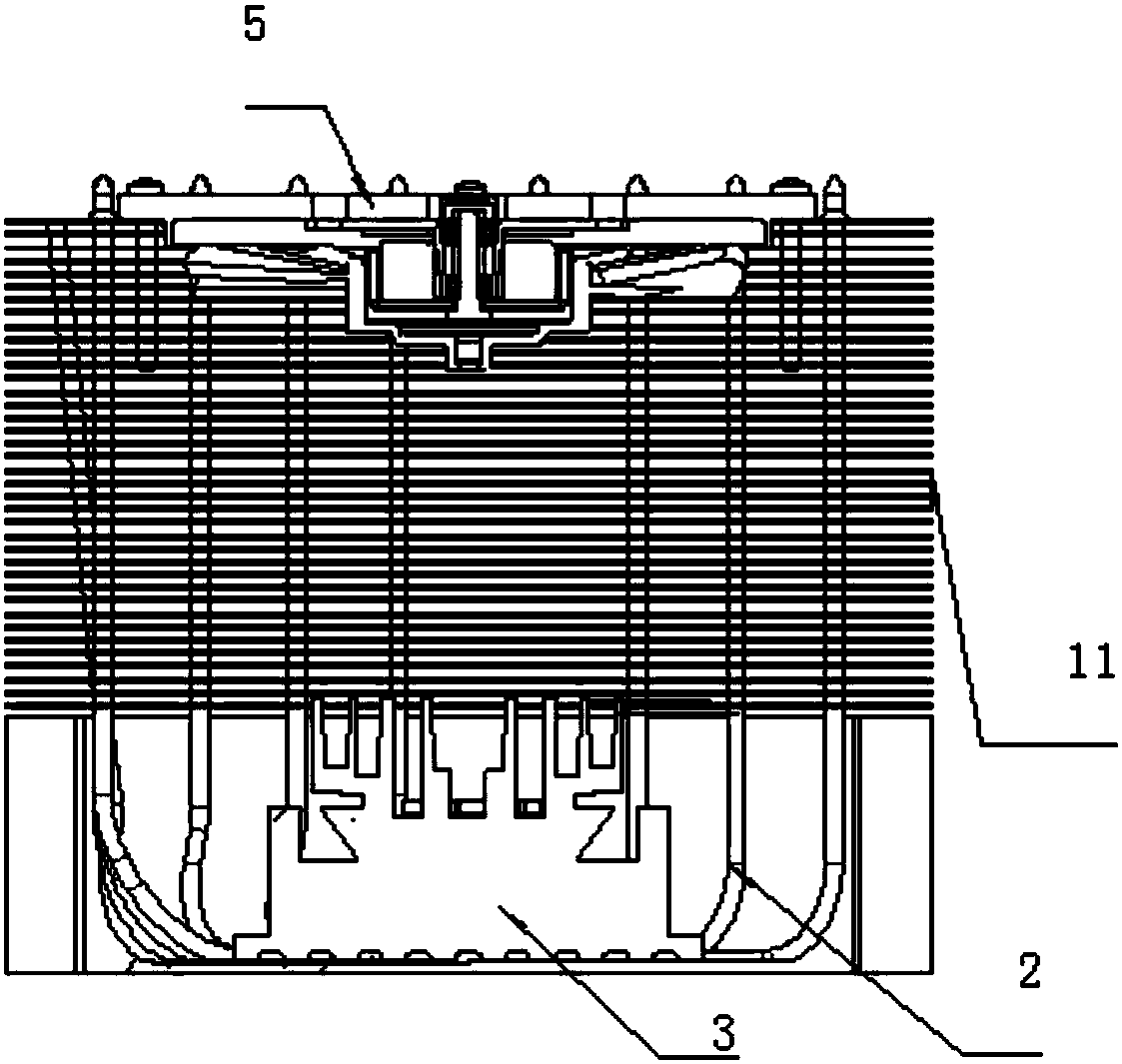

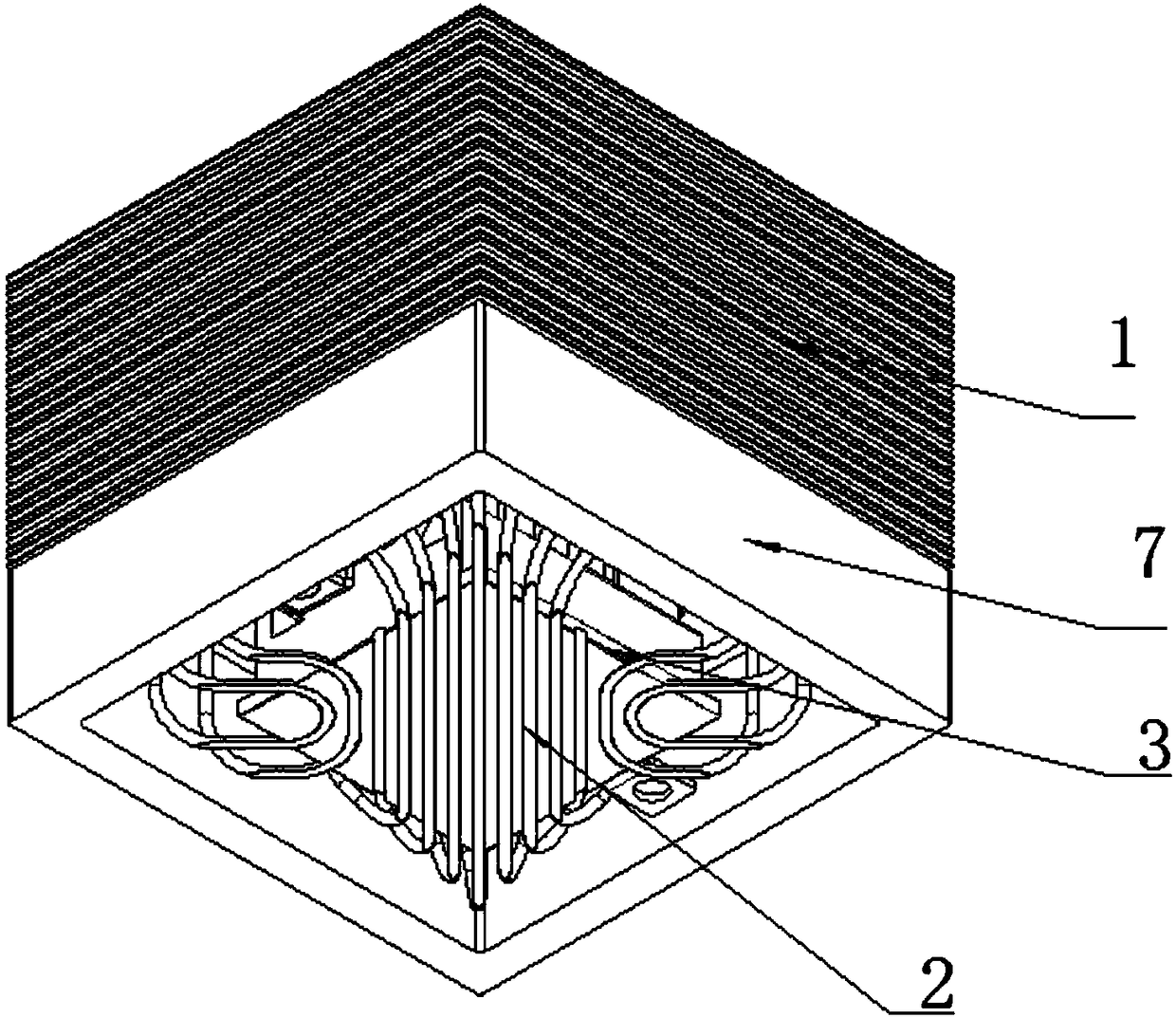

[0024] figure 1 A schematic structural diagram of a heat dissipation device according to an embodiment of the present invention is shown, figure 2 show figure 1 Sectional view of A-A in the middle. Such as Figure 1-2 As shown, the heat dissipation device provided by the embodiment of the present invention includes: a conduction rod 2 and a heat dissipation part 1 , and the conduction rod 2 supports the heat dissipation part 1 and transfers heat of an object to be dissipated to the heat dissipation part 1 .

[0025] The heat dissipation part 1 includes a plurality of heat dissipation fins 11 arranged in parallel with gaps between adjacent heat dissipation fins 11 , and the conductive rods 2 pass through the plurality of heat dissipation fins 11 in sequence and are connected to the plurality of heat dissipation fins 11 .

[0026] Now take the semiconductor cooling chip as an example to illustrate the working process of the heat dissipation device.

[0027] When the heat si...

Embodiment 2

[0030] On the basis of the first embodiment above, optionally, as figure 1 As shown, the distances between adjacent heat sinks 11 are equal to facilitate the manufacture of the heat sink 1 and reduce the cost.

[0031] exist figure 1 In the embodiment, the heat sink 11 is made of aluminum alloy, which can reduce the weight of the heat sink 1 while ensuring the heat dissipation efficiency, so that the conductive rod 2 can better support the heat sink 1 .

[0032] Preferably, the thickness of the heat sink 11 is about 0.35 mm, and the distance between adjacent heat sinks 11 is about 1.5 mm, which further reduces the volume of the heat sink 1 and facilitates installation.

[0033] Preferably, the number of conductive rods 2 is multiple, and the multiple conductive rods 2 are arranged in parallel to better support the heat dissipation part 1, transfer heat faster, and improve heat dissipation efficiency.

[0034] Further, the conduction rod 2 is roughly in the shape of a U-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com