A method for reducing TOC content in lithium battery raw materials

A raw material, lithium battery technology, applied in separation methods, chemical instruments and methods, loose filter material filters, etc., can solve the problems affecting the performance of lithium batteries, high impurity content, reduce TOC content and other impurities, reduce TOC content , the effect of enhancing the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

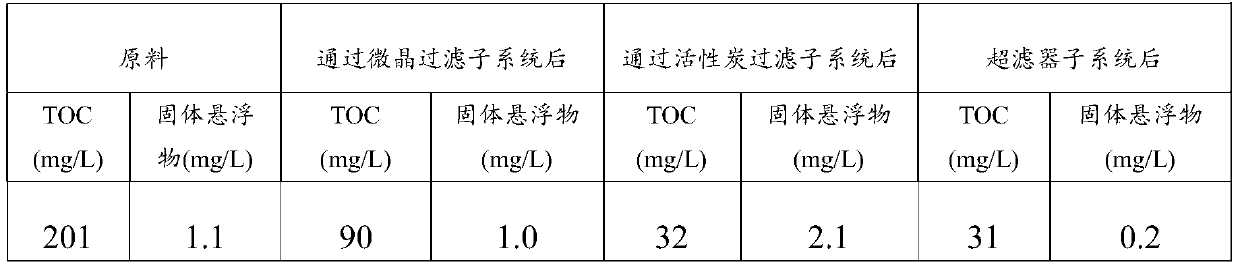

Embodiment 1

[0069] A method for reducing the TOC content in lithium battery raw materials. The slurry is firstly treated by a microcrystalline filtration subsystem, and then sequentially processed by an activated carbon filtration subsystem, a primary ultrafiltration subsystem, and a secondary ultrafiltration subsystem.

[0070] Among them, the effective use volume of the microcrystalline filtration subsystem is 20m 3 , the flow rate of the slurry through the microcrystalline filtration subsystem is 30m 3 / h, the operating temperature is 30°C, and polyvinyl chloride is used, and the particle size is 50 μm; the effective use volume of the activated carbon filtration subsystem is 20m 3 , the flow rate of the slurry through the microcrystalline filtration subsystem is 30m 3 / h, the operating temperature is 30°C, and its average pore size is 50μm; the effective use area of the primary ultrafiltration subsystem is 20m 2 , the pore size of the filter element is 0.5μm, the operating temperat...

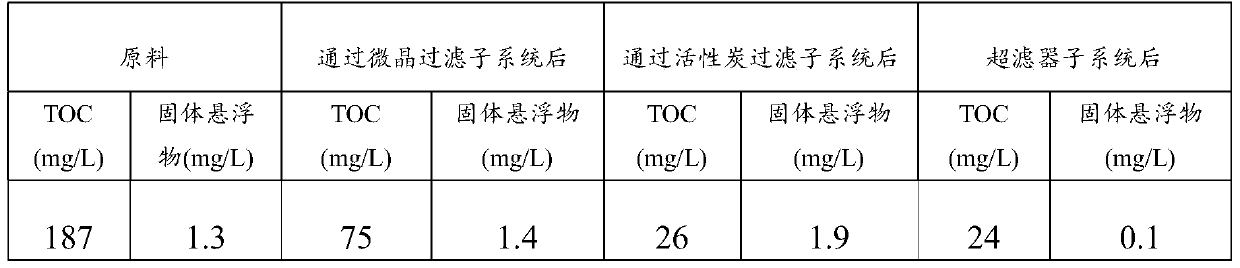

Embodiment 2

[0075] A method for reducing the TOC content in lithium battery raw materials. The slurry is firstly treated by a microcrystalline filtration subsystem, and then sequentially processed by an activated carbon filtration subsystem, a primary ultrafiltration subsystem, and a secondary ultrafiltration subsystem.

[0076] Among them, the effective use volume of the microcrystalline filtration subsystem is 20m 3 , the flow rate of the slurry through the microcrystalline filtration subsystem is 20m 3 / h, the operating temperature is 30°C, and polyvinyl chloride is used, and the particle size is 50 μm; the effective use volume of the activated carbon filtration subsystem is 20m 3 , the flow rate of the slurry through the microcrystalline filtration subsystem is 20m 3 / h, the operating temperature is 30°C, and its average pore size is 50μm; the effective use area of the primary ultrafiltration subsystem is 20m 2 , the pore size of the filter element is 0.5μm, the operating temperat...

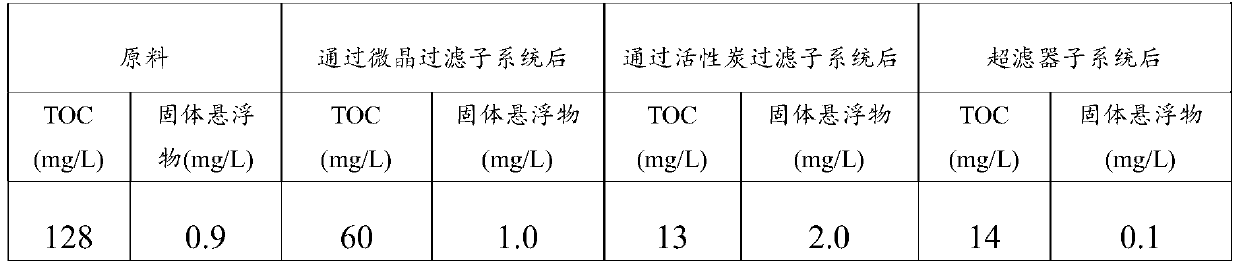

Embodiment 3

[0080] A method for reducing the TOC content in lithium battery raw materials. The slurry is firstly treated by a microcrystalline filtration subsystem, and then sequentially processed by an activated carbon filtration subsystem, a primary ultrafiltration subsystem, and a secondary ultrafiltration subsystem.

[0081] Among them, the effective use volume of the microcrystalline filtration subsystem is 15m 3 , the flow rate of the slurry through the microcrystalline filtration subsystem is 30m 3 / h, the operating temperature is 30°C, and polyvinyl chloride is used, and the particle size is 50 μm; the effective use volume of the activated carbon filtration subsystem is 30m 3 , the flow rate of the slurry through the microcrystalline filtration subsystem is 20m 3 / h, the operating temperature is 30°C, and its average pore size is 50μm; the effective use area of the primary ultrafiltration subsystem is 30m 2 , the pore size of the filter element is 0.5μm, and the operating temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com