A method for removing organic impurities of ketazine method hydrazine hydrate

A technology of organic impurities, ketazine method, applied in the direction of nitrogen and non-metallic compounds, hydrazine, etc., can solve the problems of high non-volatile matter, high final TOC content, long process, etc., and achieve the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

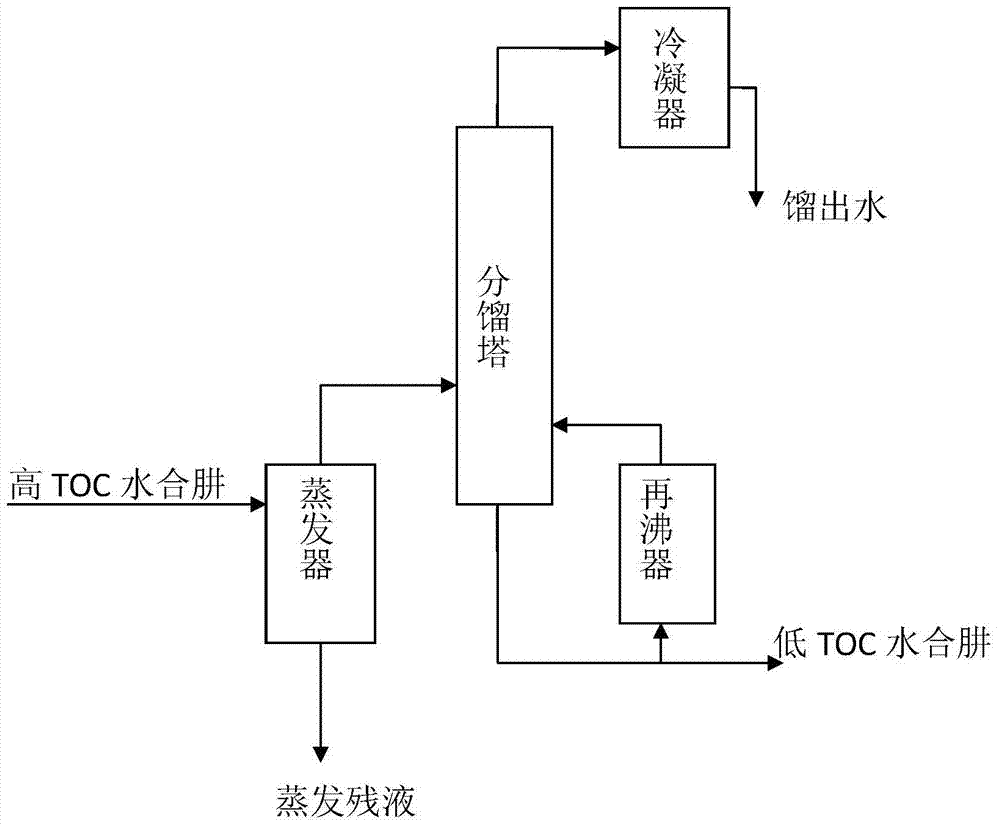

[0021] (1) Evaporation step: Send the crude hydrazine hydrate solution containing impurities into the evaporator, add half of the liquid level of 30% sodium hydroxide solution to the evaporator, about 800kg, and then add the hydrazine hydrate solution with a TOC content of 7530ppm to the evaporator 2 / 3 liquid level, the temperature of the evaporator is controlled at 122°C, and the pressure is 0.08MPa for continuous evaporation, so that it can destroy the structure of organic impurities at a higher temperature, and hydrazine hydrate and low-boiling organic impurities are evaporated in the form of gas. Refractory macromolecular organic impurities and non-volatile matter are left at the bottom of the evaporator for removal. After the evaporation amount is significantly reduced, discharge the waste liquid in the evaporator, and replace the sodium hydroxide. According to the impurities in the hydrazine hydrate, the amount of alkaline earth metals is generally 0.15~0.2% of the amount...

Embodiment 2

[0024] (1) Evaporation step: Send the crude hydrazine hydrate solution containing impurities into the evaporator, add 800kg of potassium hydroxide solid into the evaporator, and then add the hydrazine hydrate solution with a TOC content of 7500ppm to 2 / 3 of the liquid level to control evaporation The temperature of the device is 125°C, and the pressure is 0.08MPa for continuous evaporation, so that it can destroy the structure of organic impurities at a higher temperature. Hydrazine hydrate and low-boiling organic impurities are evaporated in the form of gas. The non-volatiles remained at the bottom of the evaporator for removal. After the evaporation amount is significantly reduced, discharge the waste liquid in the evaporator, and replace the potassium hydroxide. According to the impurities in the hydrazine hydrate, the amount of alkaline earth metals is generally 0.15~0.2% of the amount of hydrazine hydrate required to be treated;

[0025] (2) Fractionation step: Send the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com