Amorphous silicon-aluminum catalytic material preparation method

A technology of amorphous silica-alumina and catalytic materials, applied in chemical instruments and methods, catalysts, hydrocarbon cracking and hydrocarbon production, etc., can solve problems such as increased preparation costs, unfriendly templating agents, and obstacles to the industrial application of ordered mesoporous materials , to achieve the effects of unobstructed channels, enhanced accessibility and excellent cracking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] Example 1

[0026] This example illustrates the preparation method of the present invention.

[0027] At room temperature the water glass solution (concentration 80gSiO 2 / L) is placed in a beaker, dripped ammonia water (content 17%) under stirring, and after continuing to stir for 10 minutes, the Al 2 (SO 4 ) 3 Solution (concentration 90gAl 2 o 3 / L) to add and adjust the final pH value of the slurry to 8.5, raise the temperature to 50°C and stir at a constant temperature for 3 hours; filter the resulting solid precipitate according to the dry basis of the precipitate: HCl: H 2 The weight ratio of O=1:0.08:10 is contacted with dilute hydrochloric acid at 50°C for 0.5 hours. After filtering and washing, repeat the process of contacting with acid once. After filtering, dry the silicon-aluminum catalyst material, which is denoted as HSA- 1.

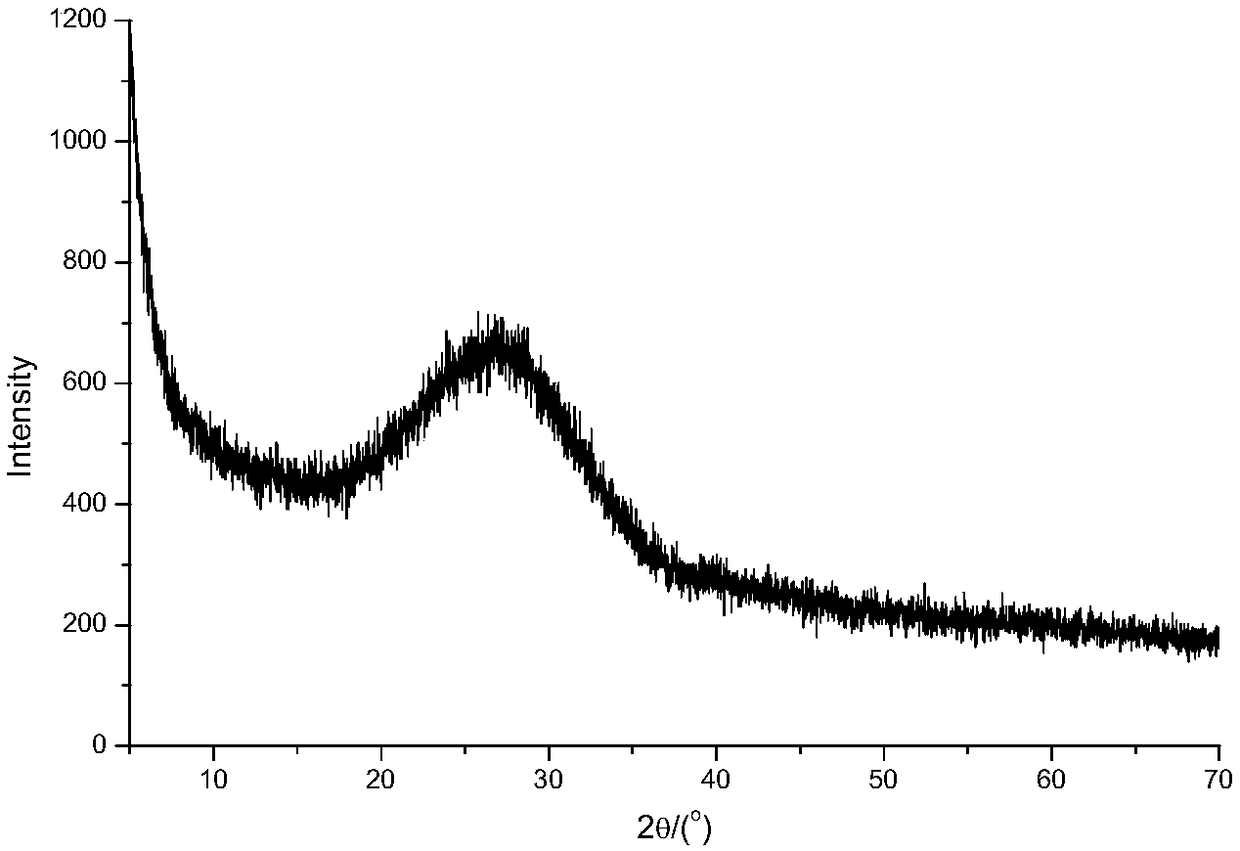

[0028] The X-ray diffraction pattern of HSA-1 is shown in figure 1 , where diffuse diffraction peaks appear around 25°-27°, ...

Example Embodiment

[0029] Example 2

[0030] This example illustrates the preparation method of the present invention.

[0031] The measured water glass solution (concentration 80gSiO 2 / L) placed in a beaker and heated to 40 ° C, under stirring, a quantitative concentration of 1M sodium hydroxide solution was added to it, and after continuing to stir for 10 minutes, the Al 2 (SO 4 ) 3 Solution (concentration 90gAl 2 o 3 / L) Add and adjust the final pH value of the slurry to 10.0, continue to heat up to 60°C and stir at constant temperature for 1 hour; filter the resulting solid precipitate according to the dry basis of the precipitate: H 2 SO 4 :H 2 The weight ratio of O=1:0.15:15 was contacted with dilute sulfuric acid solution at 40°C for 1 hour, filtered and washed with water, and then dried to obtain a silicon-aluminum catalytic material, which was designated as HSA-2.

[0032] The X-ray diffraction pattern of HSA-2 has figure 1 The characteristics shown, there are diffuse diffract...

Example Embodiment

[0033] Example 3

[0034] This example illustrates the preparation method of the present invention.

[0035] Put the measured amount of tetraethoxy silicon (TEOS) in the beaker and add a small amount of deionized water, stir and heat up to 50°C, then slowly add a quantitative concentration of 1M sodium hydroxide solution into it, and continue stirring for 30 minutes , Al(NO 3 ) 3 Solution (concentration 60gAl 2 o 3 / L) to add and adjust the final pH value of the slurry to 10.5, continue to heat up to 80°C and stir at a constant temperature for 2 hours; after filtering, the resulting solid precipitate is calculated on a dry basis of the precipitate: HCl: H 2 The weight ratio of O=1:0.06:10 was contacted with dilute hydrochloric acid at room temperature for 1 hour, filtered and washed with water, and then dried to obtain a silicon-aluminum catalytic material, which was designated as HSA-3.

[0036] The X-ray diffraction pattern of HSA-3 has figure 1 The characteristics sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap