Twin-roll thin strip continuous casting solidification simulation device and method

A twin-roll thin strip continuous casting and solidification simulation technology, which is applied in the field of twin-roll thin strip continuous casting solidification simulation devices, can solve problems such as not considering the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, the twin-roll strip continuous casting and solidification simulation device and method according to the embodiment of the present invention will be described in detail.

[0015] Twin-roll thin strip continuous casting solidification simulation device

[0016] Hereinafter, a twin-roll strip continuous casting solidification simulation device according to an embodiment of the present invention will be described in detail with reference to the drawings.

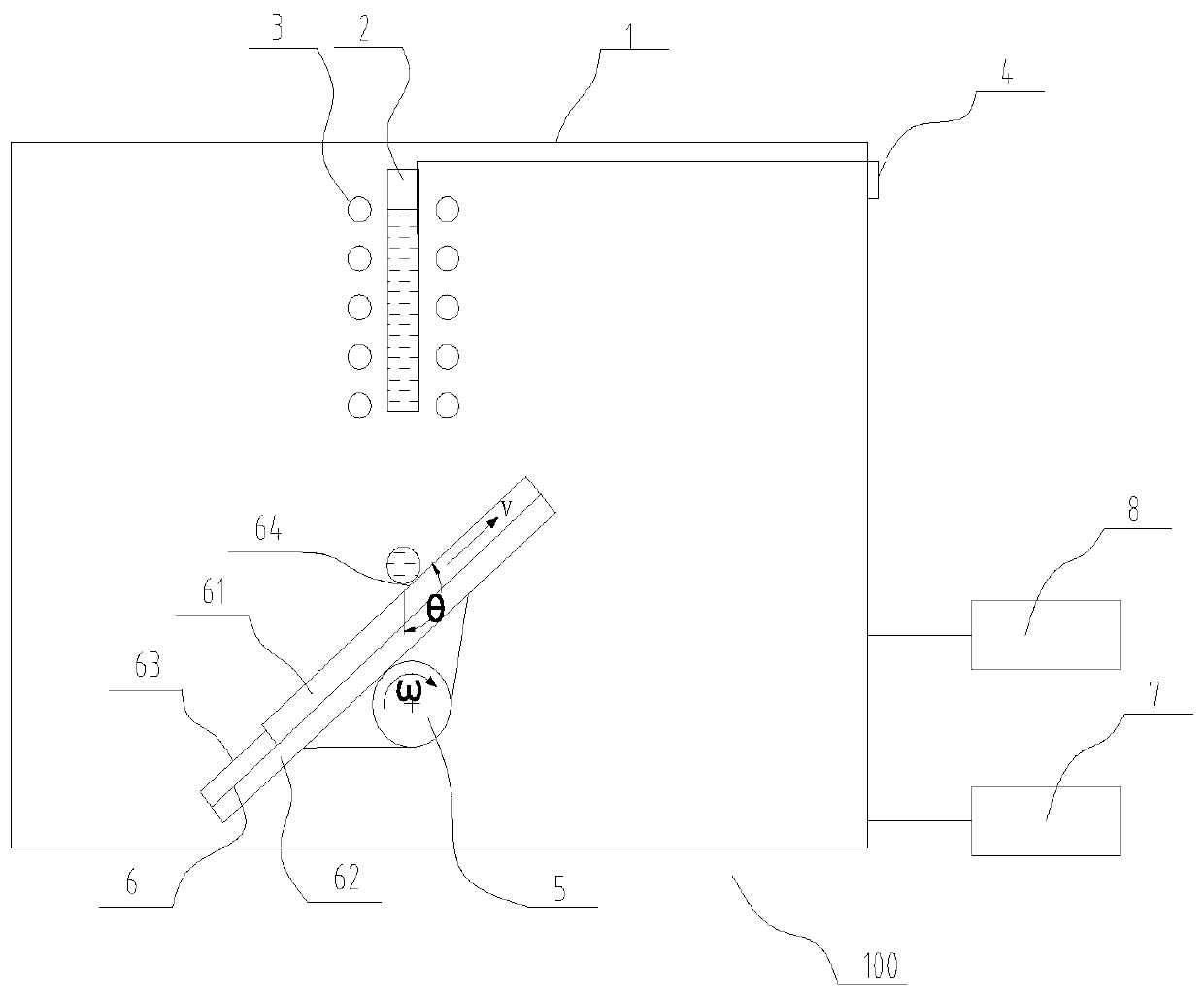

[0017] Such as figure 1 As shown, the twin-roll strip continuous casting solidification simulation device 100 involved in the embodiment of the present invention includes a vacuum chamber 1, a melting crucible 2, a heating element 3, a temperature detection element 4, a rotating part 5, and a rotating drive element (not shown in the figure). ) and the cooling substrate 6. Wherein, the melting crucible 2 , the heating element 3 , the temperature detecting element 4 , the rotating part 5 and the cooling base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com