Method of replacing sliding bearing on weighing arm supporting shaft of ladle turret of continuous casting machine

A technology of ladle turret and sliding bearing, which is applied in casting equipment, casting molten material container, metal processing equipment, etc., can solve the problems of long service life and affecting the safe operation of continuous casting production line, and achieve the reduction of troubleshooting time, Improve construction efficiency and enhance practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

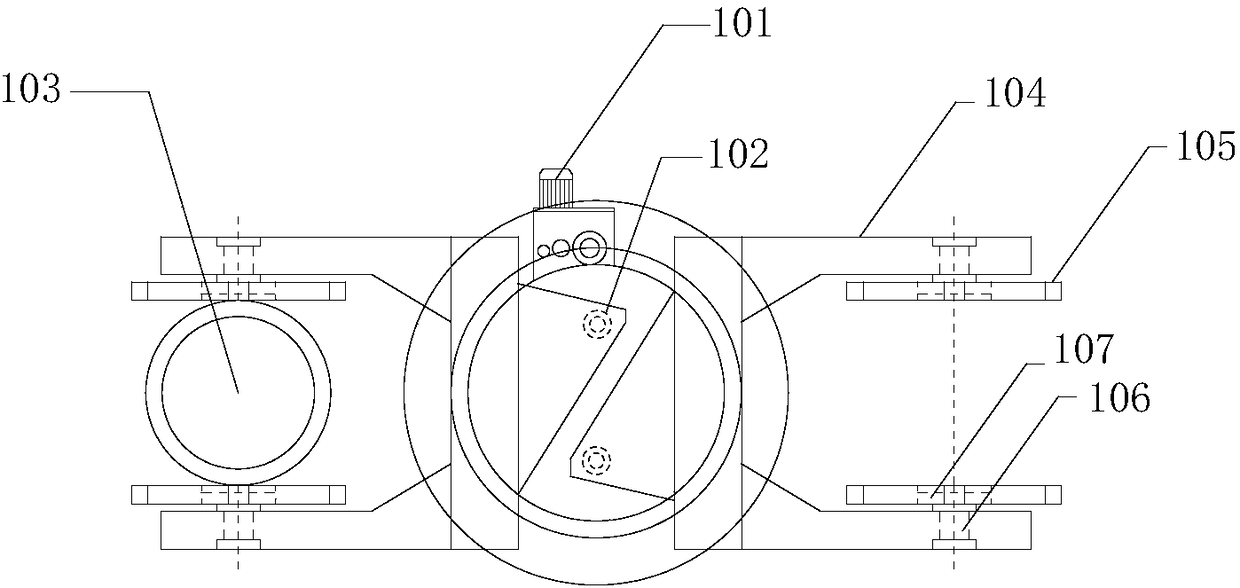

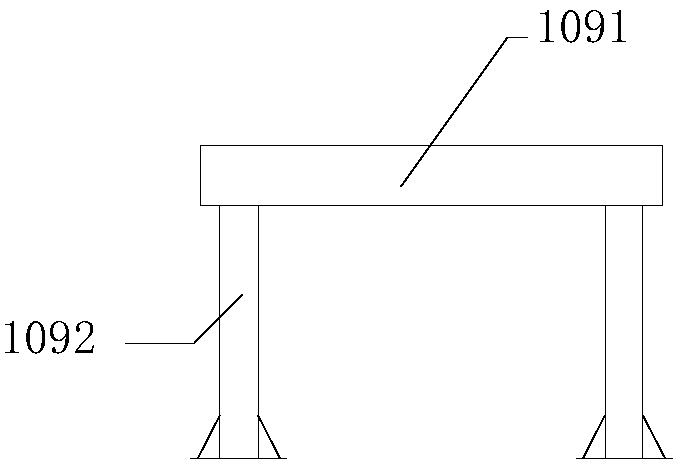

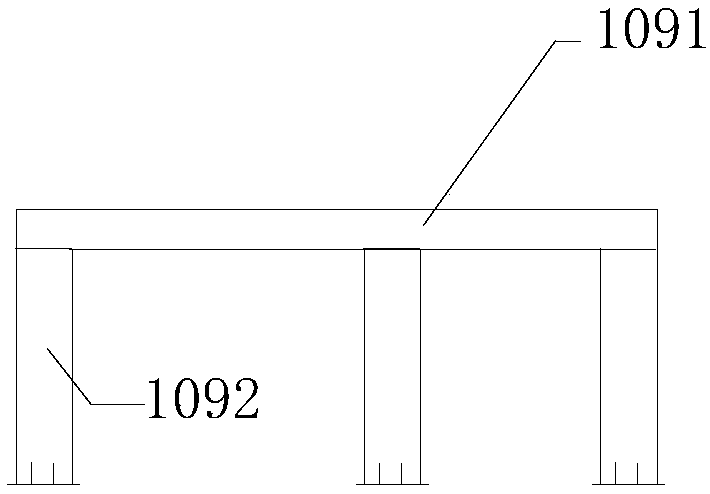

[0056] Such as Figure 1-17As shown, the present invention discloses a method for replacing the sliding bearing on the support shaft of the weighing arm of the ladle turntable of the continuous casting machine. The lifting arm 104 and the weighing arm 105 of the turntable are fixed together by the support shaft 106. Specifically , the method includes the following steps:

[0057] Step S1, after turning the bale turret to the maintenance position and lowering the lifting arm 104 to the lowest position, cut off the hydraulic system and transmission system of the bale turret of the continuous casting machine; that is, to drive the hydraulic pump and the bale turret Motor 101 power failure listing, close lifting arm 104 lifting hydraulic cylinder 102 inlet and outlet oil circuit valve; figure 1 In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com