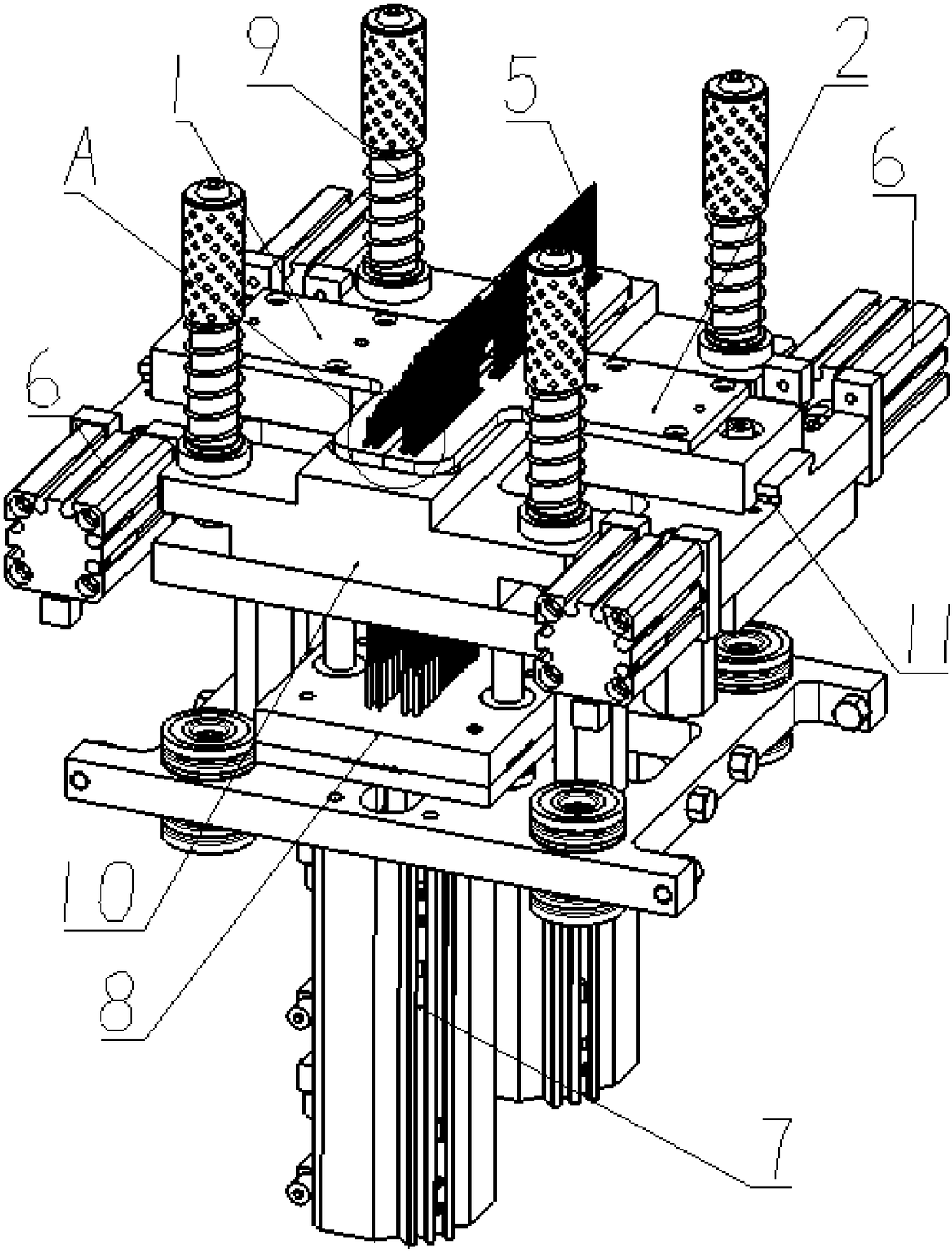

Multi-pin clamping mechanism

A needle clamp and pin insertion technology, which is applied in the direction of workpiece clamping devices, metal processing, metal processing equipment, etc., can solve the problems of being unable to adapt to the assembly of various pins, achieve easy clamping or loosening, improve clamping efficiency, The effect of low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

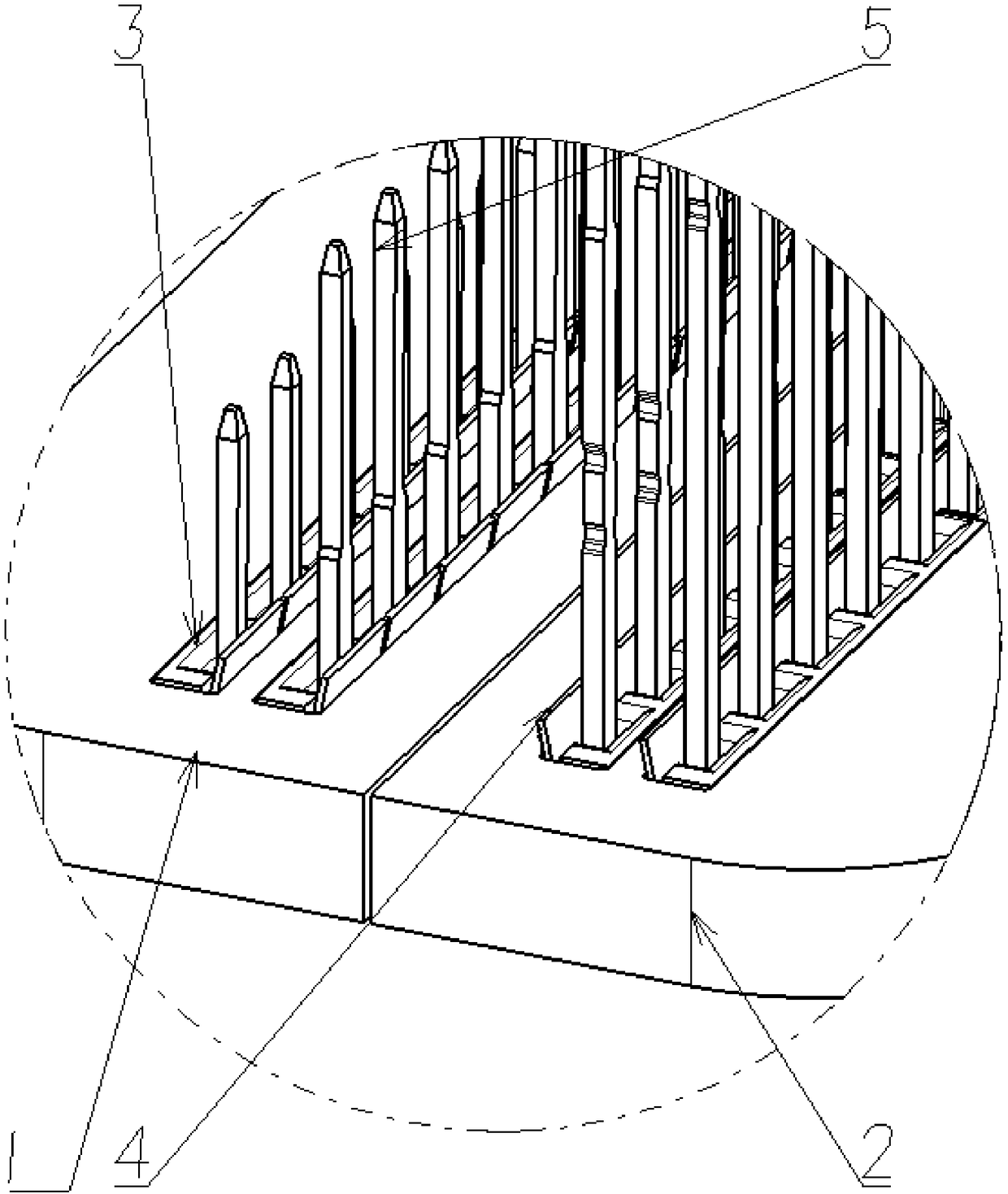

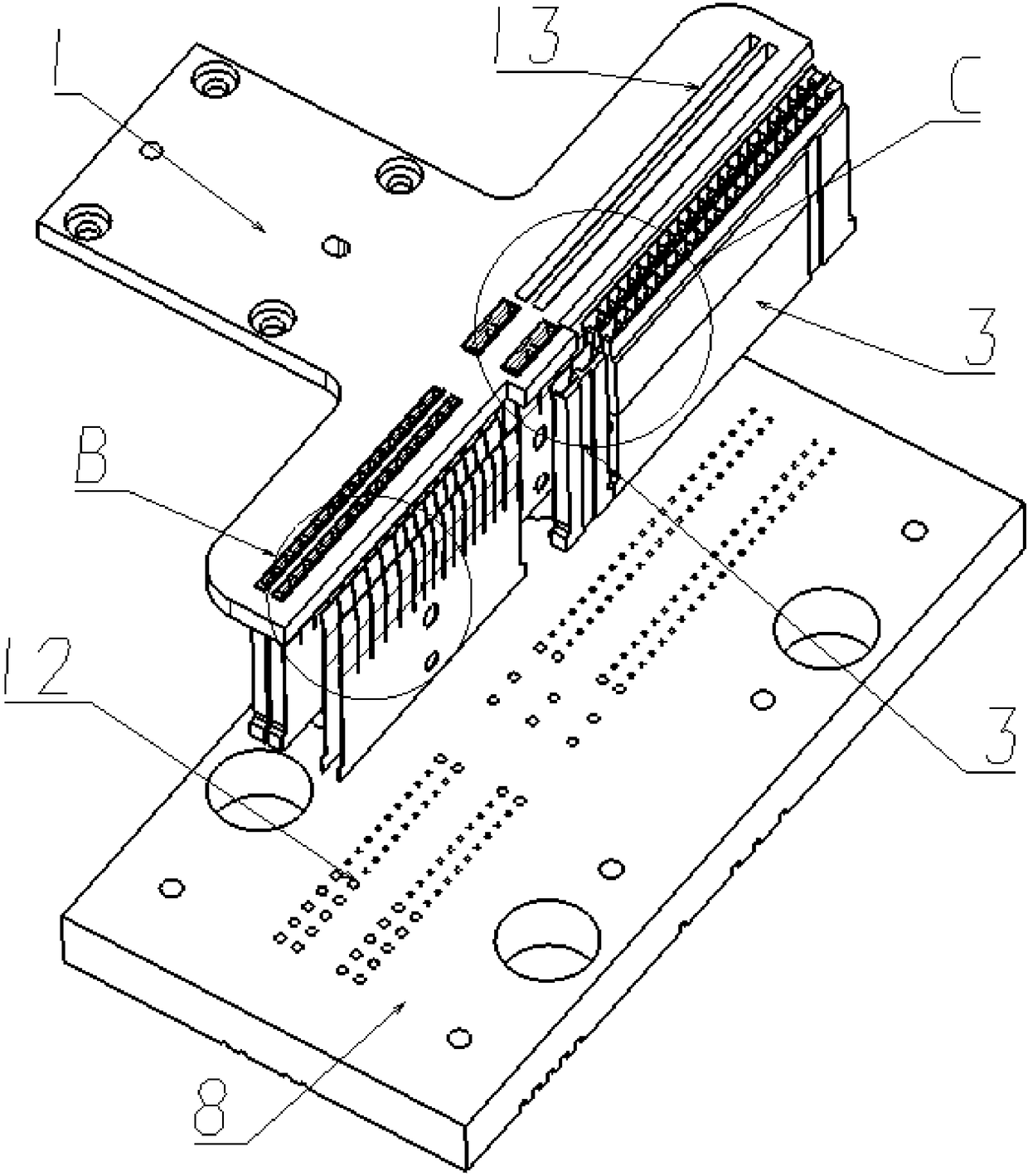

[0033] In order to achieve the purpose of the present invention, a multi-needle clamping mechanism includes: a slot cover 3 arranged vertically and provided with a through opening along the length direction. Surrounded by a plane; the shrapnel 4 is arranged in parallel with the groove sleeve 3, and the shrapnel 4 has a curved portion 16 and a vertical portion 17 respectively along the length direction. 16 is bent away from the groove sleeve 3, and the gap between the groove sleeve 3 and the shrapnel 4 constitutes a space for the pin 5 to pass through; the T-shaped plate has a rectangular hole 13, and the rectangular hole 13 accommodates several combined groove sleeves 3 and the elastic piece 4, the T-shaped plate has a degree of freedom of translation along the direction perpendicular to the groove sleeve 3 or the elastic piece 4, the rectangular hole 13 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com