Egg picking robot

A robot and egg tray technology, which is applied in the field of egg picking robots, can solve the problems of high noise, separation and placement of pneumatic grippers, and the inability to grab eggs, etc., to achieve the effect of improving the degree of automation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

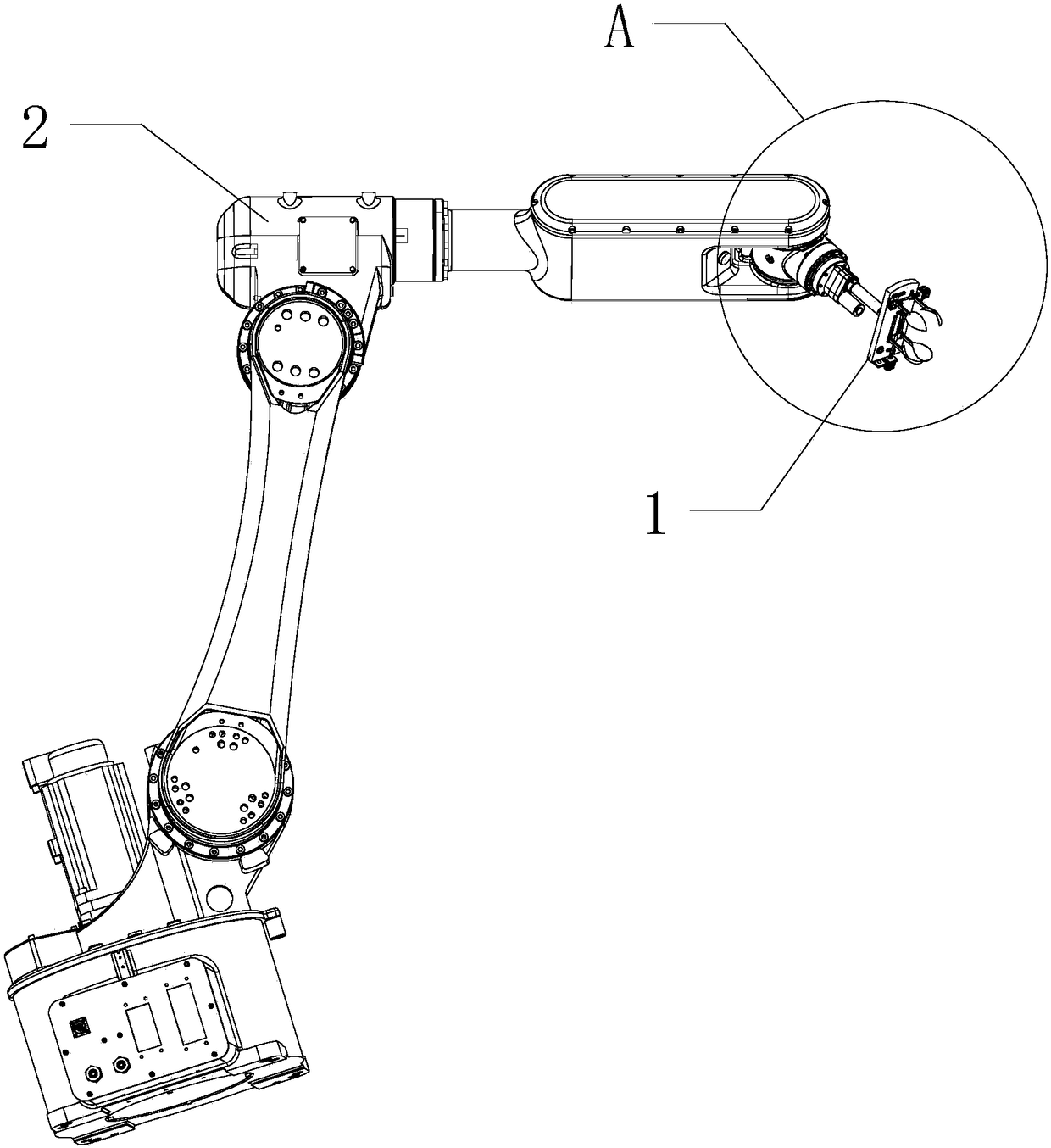

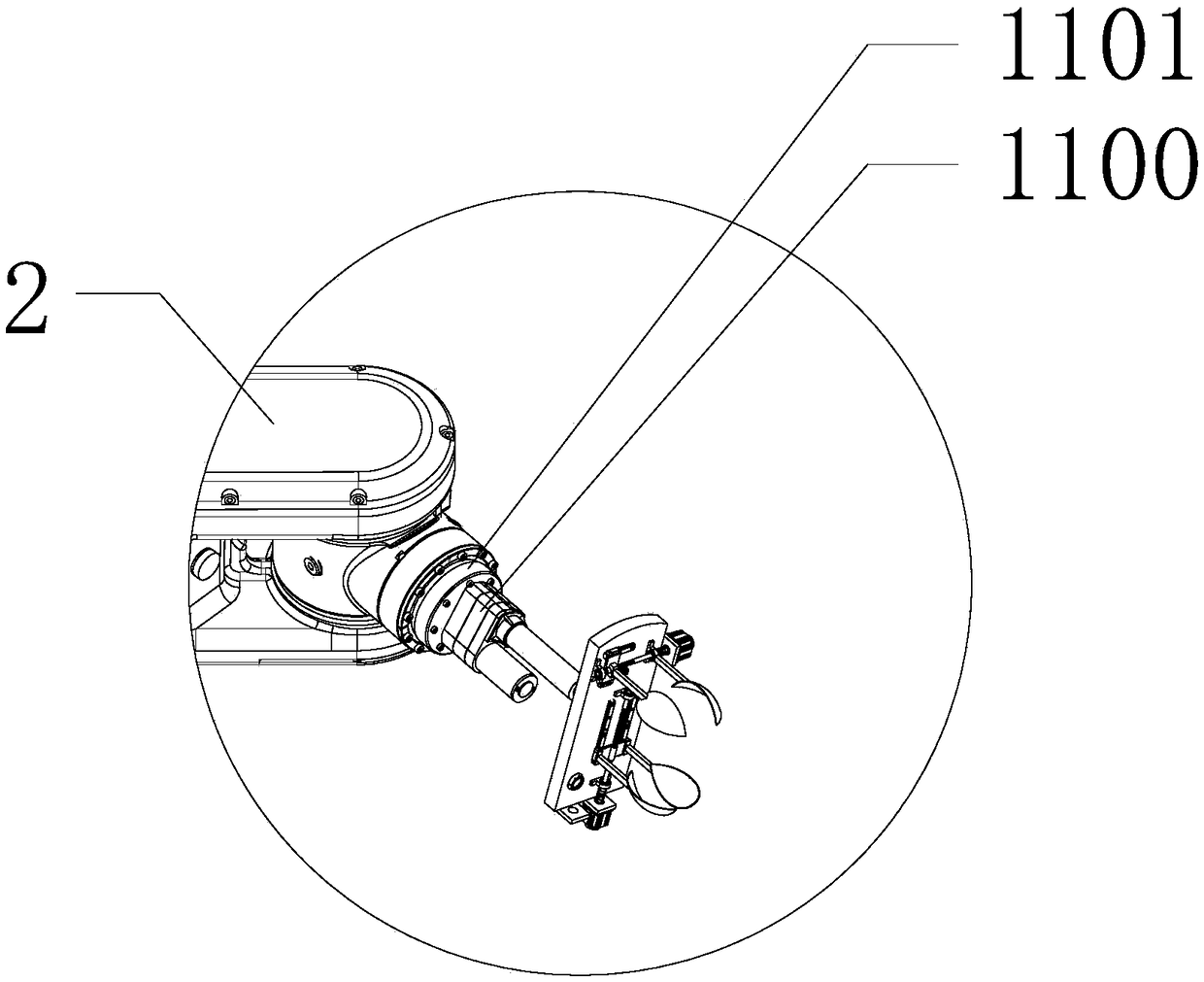

[0074] Embodiment: a kind of egg picking robot, its structure is as Figure 1-6 shown, including:

[0075] The six-joint robot arm 2 and the gripper 1 installed on the wrist of the six-joint robot arm 2 have a processing system (not shown in the figure).

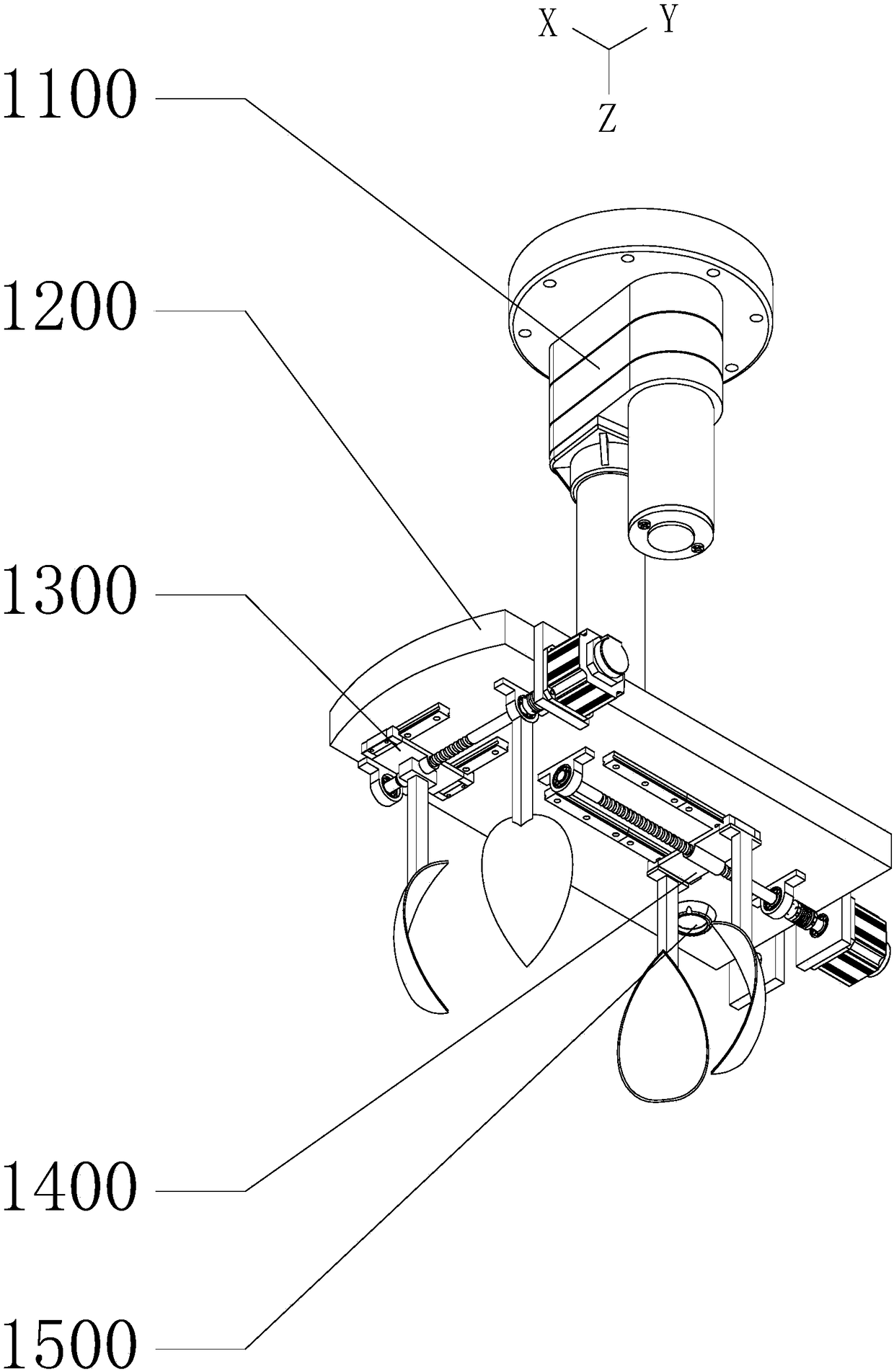

[0076] The jaw 1 includes a base plate 1200 and a lifting mechanism 1100 . The lifting mechanism 1100 is preferably an electric cylinder, the piston rod of the electric cylinder is fixedly connected to the upper surface of the substrate 1200 , and the cylinder seat of the electric cylinder is fixedly connected to the flange 1101 . The electric cylinder is used to drive the substrate 1200 to move along the Z axis.

[0077] A Y-axis egg clamping mechanism 1300 , an X-axis egg clamping mechanism 1400 and an image acquisition mechanism 1500 are mounted on the base plate 1200 . The image acquisition mechanism 1500 includes a second camera 1501 installed on the lower surface of the substrate 1200 , a camera mounting plate 1502 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap