Shaver tool bit

A razor and cutter head technology, which is applied in the field of razor cutters, can solve the problems of reducing production costs, fragile ceramic cutter heads, etc., and achieves the effects of reducing production costs, not easy to wear, and increasing cutting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

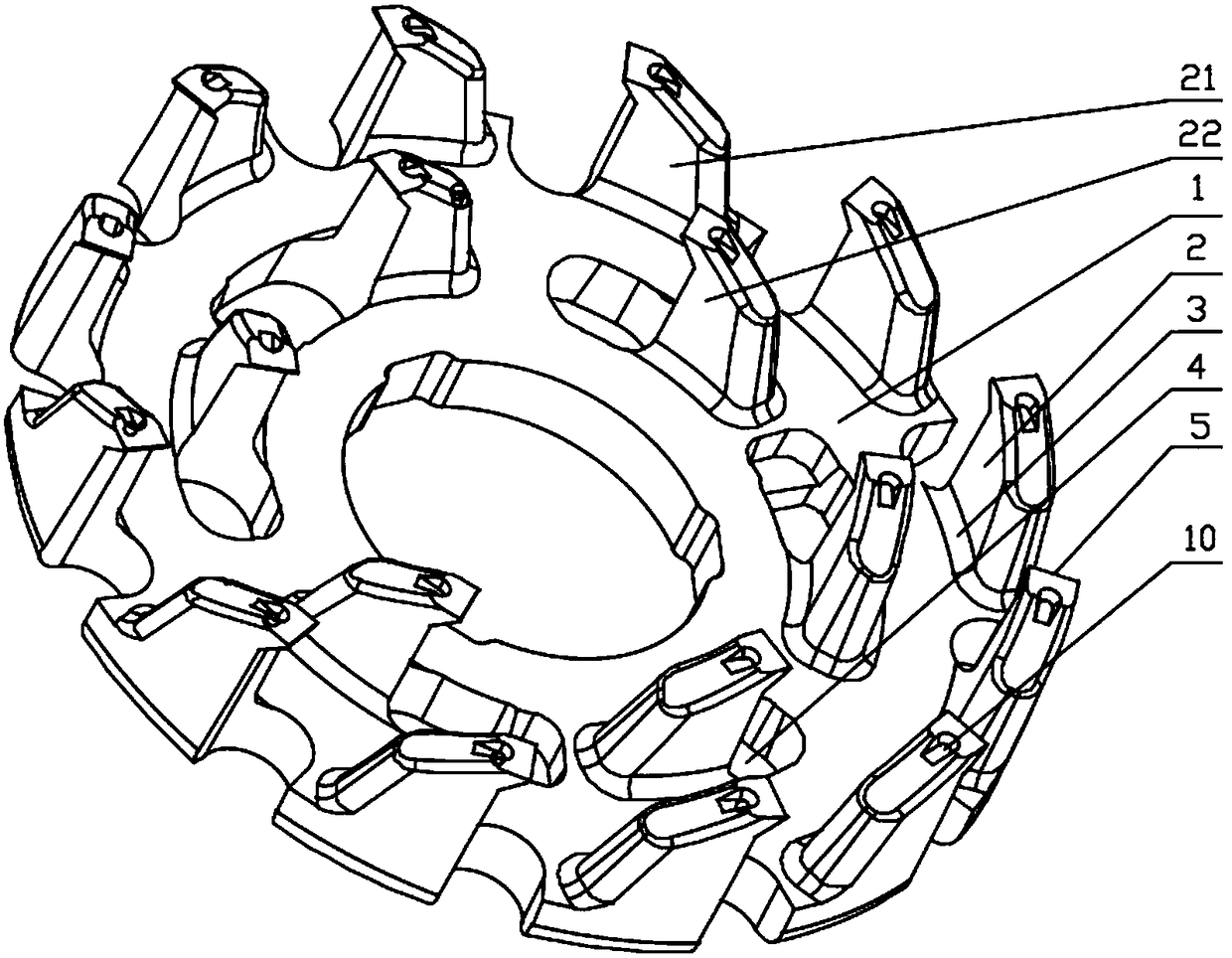

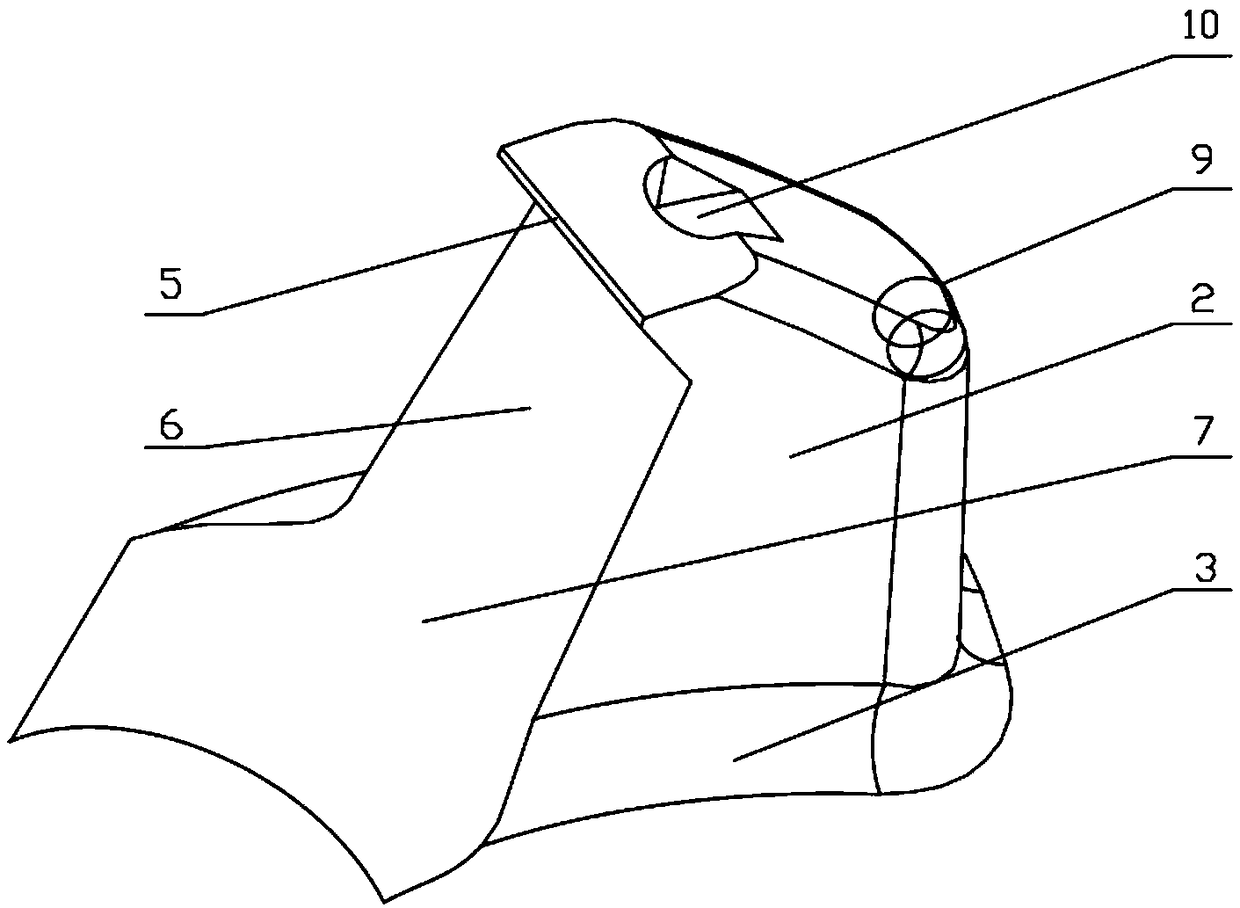

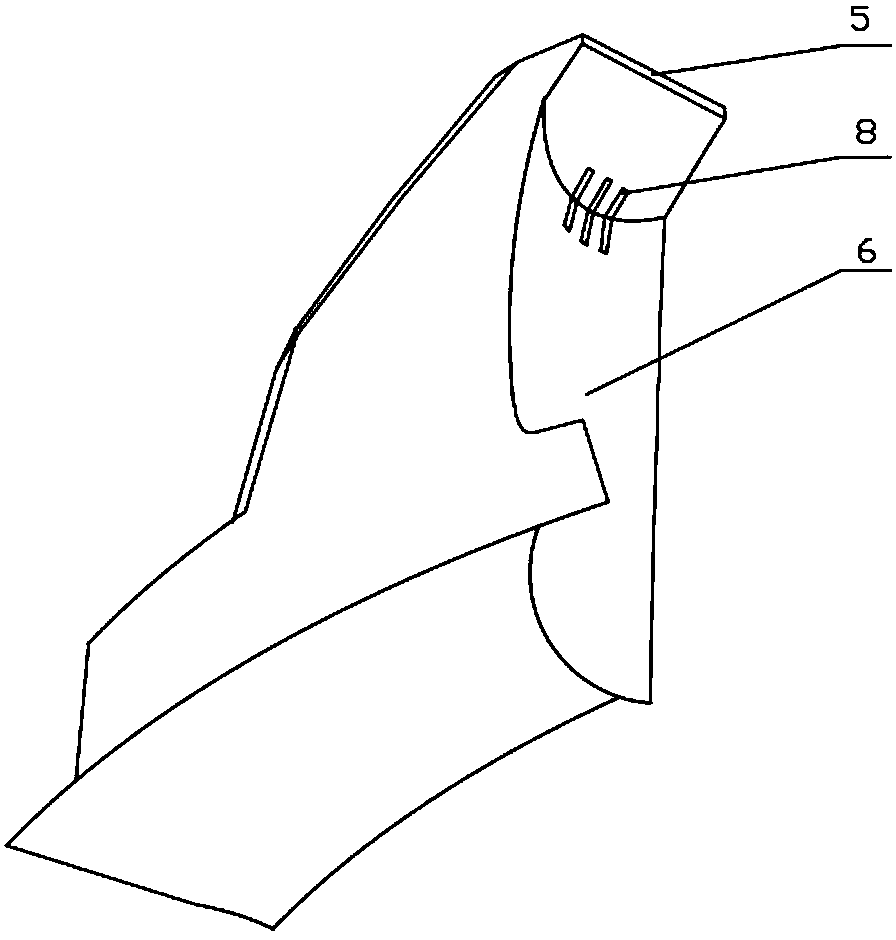

[0021] combine Figure 1-3 To further describe the present invention: the shaver head is made of integrally formed ceramic material. This razor head comprises chassis 1 and cutter head 2, is also provided with plural base 3 on chassis 1, is advisable with double-ring base, is about to base 3 and is divided into two annular arrays, is respectively outer ring base and Inner ring base. A cutter head 2 is set on each base 3, so that the cutter head 2 is also a double-ring cutter head, that is, the cutter head 2 is divided into two annular arrays, which are respectively an outer ring cutter head 21 and an inner ring cutter head 22, and the outer ring cutter head The number of heads 21 is twice the number of inner ring cutter heads 22, and the position of one inner ring cutter head 22 and two adjacent outer ring cutter heads 21 forms an isosceles triangle. A corresponding waste material hole 4 is provided in front of each base 3 , and the inner wall of the waste material hole 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com