Integrated mini-type sludge solid-liquid separation device

A solid-liquid separation and integrated technology, applied in the environmental field, can solve the problems of huge related equipment, waste, unsuitable for urban sludge treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

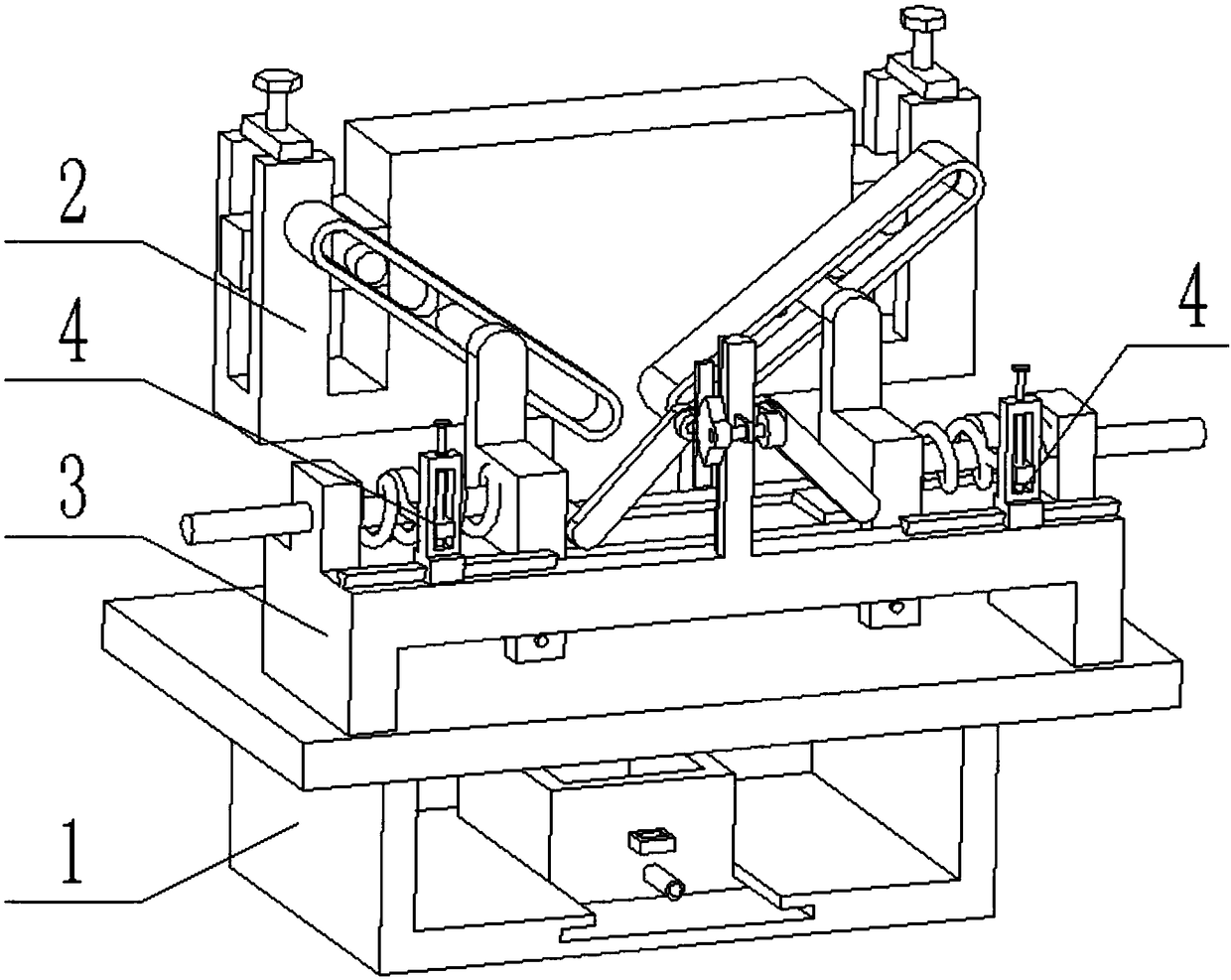

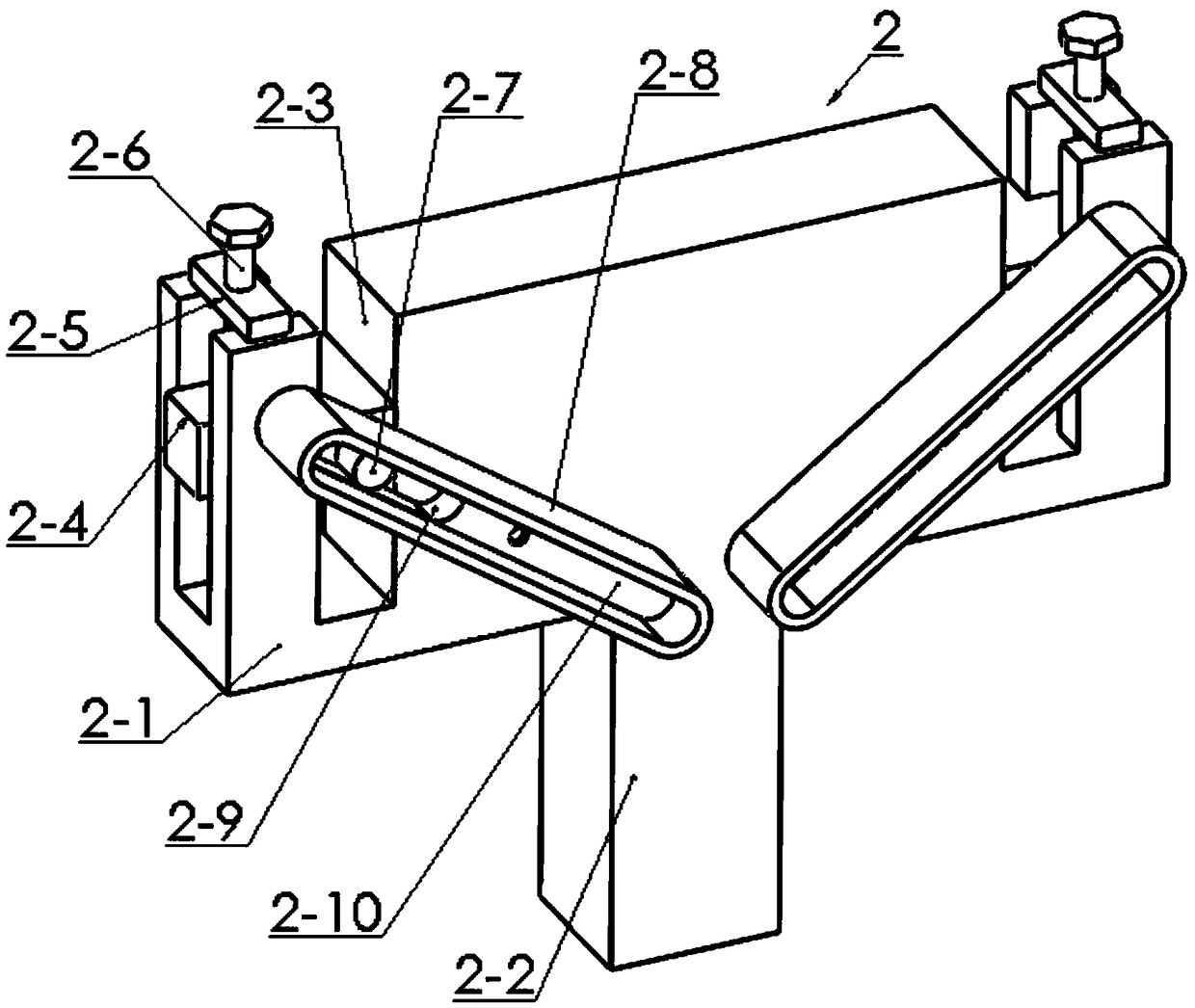

[0023] Combine below Figure 1-8 Describe this embodiment, the present invention relates to the field of environmental technology, more specifically an integrated micro-sludge solid-liquid separation device, including a guide base 1, a beating part 2, a beating drive device 3 and a beating buffer adjustment part 4, the device The beating amplitude of the beating part can be controlled; the compression degree of the spring on the spring sleeve rod can also be adjusted through the beating buffer adjusting part, thereby adjusting the beating buffer degree.

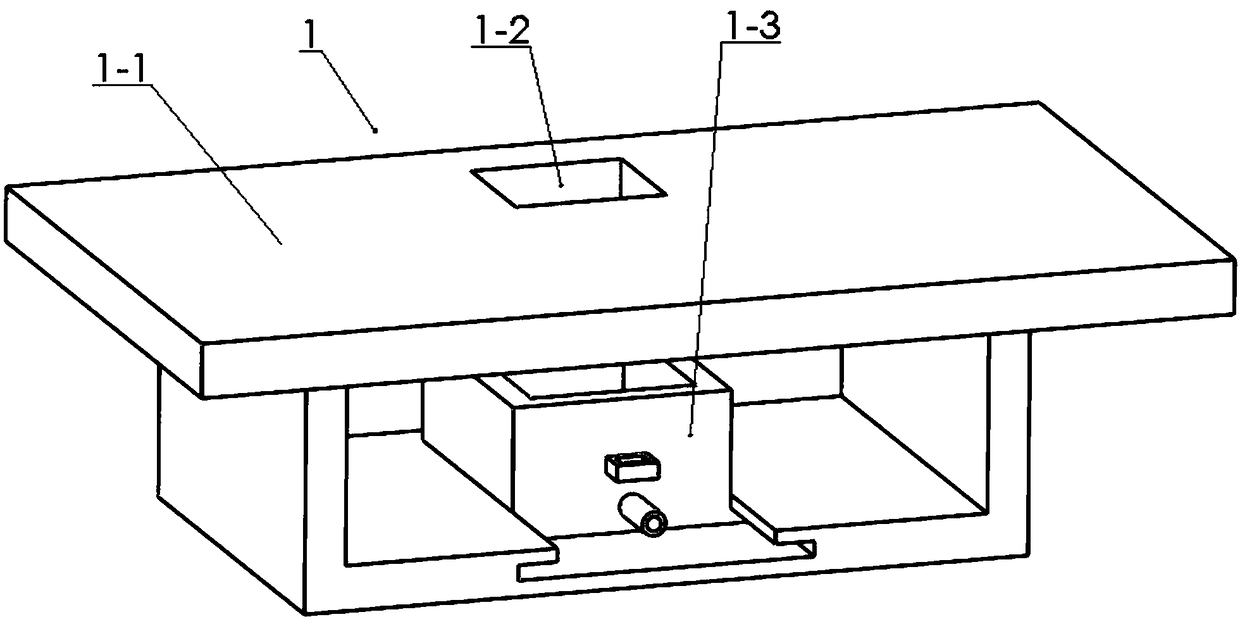

[0024] The guide base 1 includes a base 1-1, a guide groove 1-2 and a sludge tank 1-3, the front end of the base 1-1 is hollowed out, and the sludge tank 1-3 is slidably connected to the inside of the base 1-1. The lower end of the mud box 1-3 is connected and communicated with a water outlet pipe, the upper end of the base 1-1 is provided with a guide groove 1-2, and the guide groove 1-2 communicates with the inside of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com