A kind of antifreeze cleaning fracturing fluid and preparation method thereof

A technology for cleaning fracturing fluids and surfactants, applied to chemical instruments and methods, and drilling compositions, etc., can solve the problems of high energy consumption, easy to cause freeze blockage, high freezing point, etc., and achieve simple preparation process and formation damage small size, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In the present embodiment, the formula of the antifreeze cleaning fracturing fluid is as follows:

[0044]

[0045] Preparation: Add the formulated amount of glycerol and sodium chloride to water at room temperature, then add N-(cis-docos-13-enoic acid amidopropyl)-N,N-dimethyl-N -Propyl sulfobetaine, stirred until N-(cis-docos-13-enoic acid amidopropyl)-N,N-dimethyl-N-propyl sulfobetaine is fully dissolved and mixed Evenly obtain antifreeze fracturing fluid.

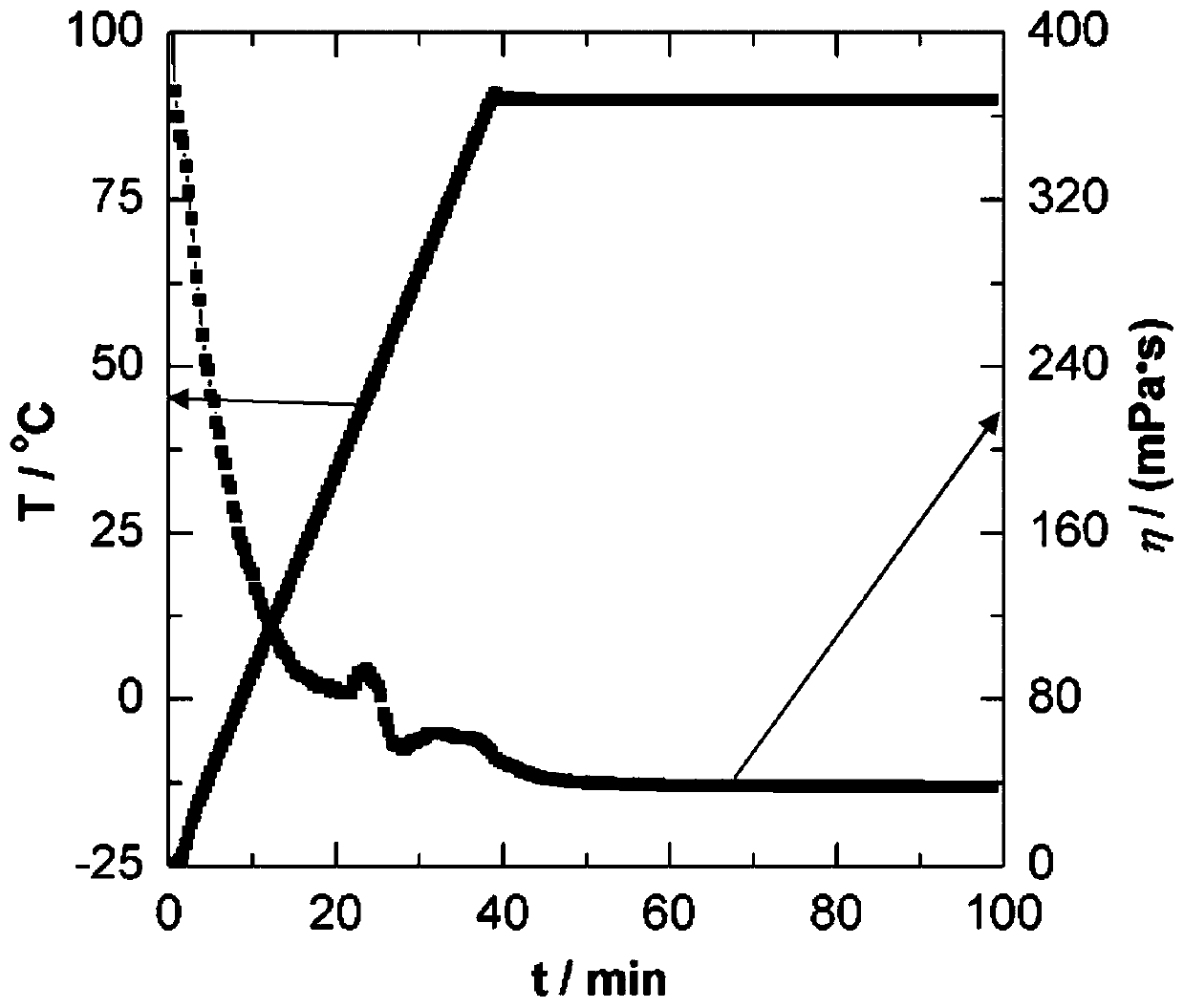

[0046] The rheological properties of the prepared solutions were tested using a rotational rheometer (Anto Paar, MCR 301). At a shear rate of 170s -1 The relationship between the viscosity of the fracturing fluid as a function of temperature and time was tested. Test initial temperature -25°C, at 3°C·min -1 The heating rate is raised to 90°C, and then sheared at a constant temperature for 60 minutes. The test results are shown in figure 1 . Depend on figure 1 It can be seen that at the initial temperatu...

Embodiment 2

[0048] In the present embodiment, the formula of the antifreeze cleaning fracturing fluid is as follows:

[0049]

[0050] Preparation: Add the formulated amount of glycerol and sodium chloride to water at room temperature, then add N-(cis-docos-13-enoic acid amidopropyl)-N,N-dimethyl-N -Propyl sulfobetaine, stirred until N-(cis-docos-13-enoic acid amidopropyl)-N,N-dimethyl-N-propyl sulfobetaine is fully dissolved and mixed Evenly obtain antifreeze fracturing fluid.

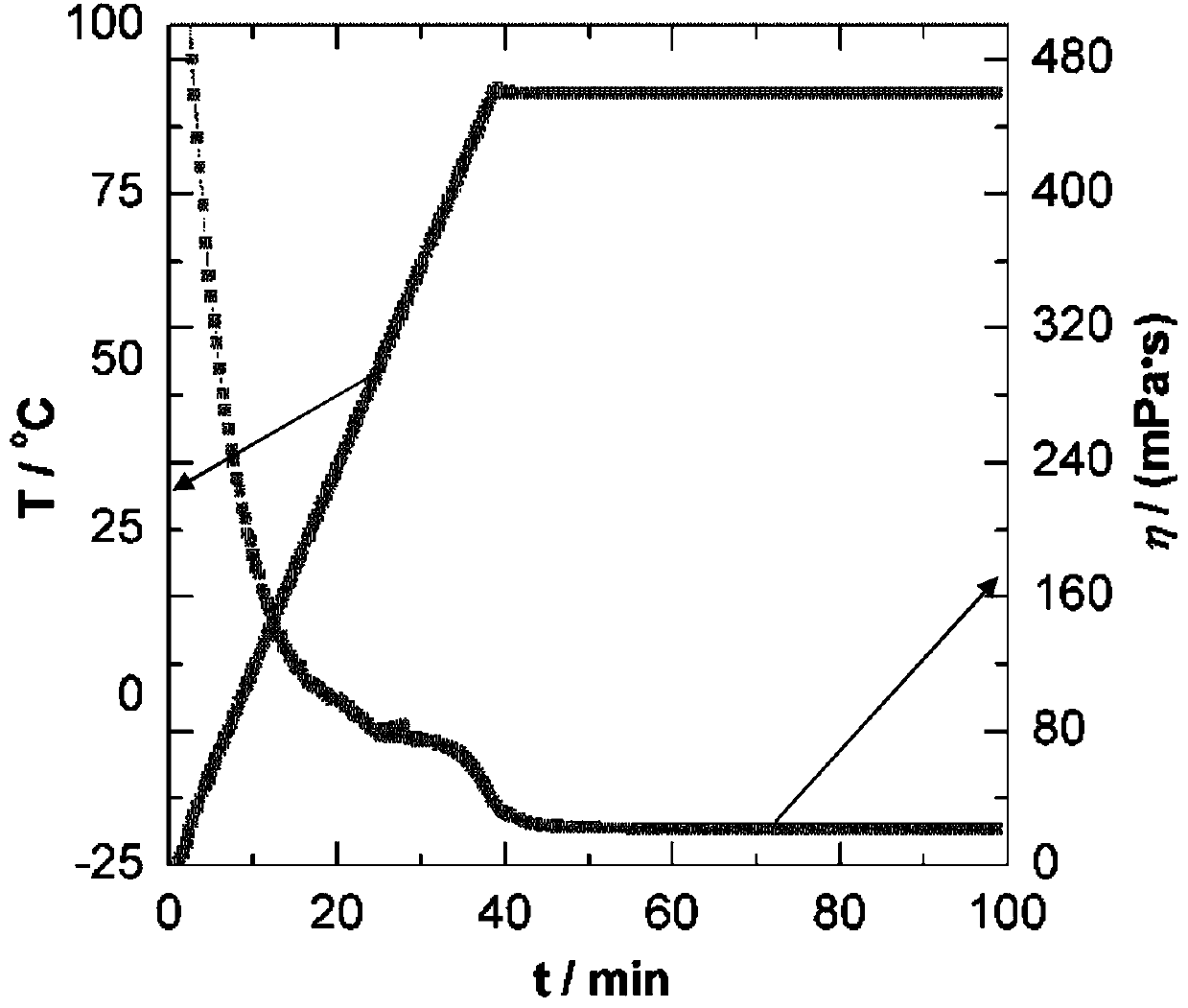

[0051] The rheological properties of the prepared solutions were tested using a rotational rheometer (Anto Paar, MCR 301). At a shear rate of 170s -1 The relationship between the viscosity of the fracturing fluid as a function of temperature and time was tested. Test initial temperature -25°C, at 3°C·min -1 The heating rate is raised to 90°C, and then sheared at a constant temperature for 60 minutes. The test results are shown in figure 2 . Depend on figure 2 It can be seen that at the initial tempera...

Embodiment 3

[0053] In the present embodiment, the formula of the antifreeze cleaning fracturing fluid is as follows:

[0054]

[0055] Preparation: Add the formulated amount of glycerol and sodium chloride to water at room temperature, then add N-(cis-docos-13-enoic acid amidopropyl)-N,N-dimethyl-N -Propyl sulfobetaine, stirred until N-(cis-docos-13-enoic acid amidopropyl)-N,N-dimethyl-N-propyl sulfobetaine is fully dissolved and mixed Evenly obtain antifreeze fracturing fluid.

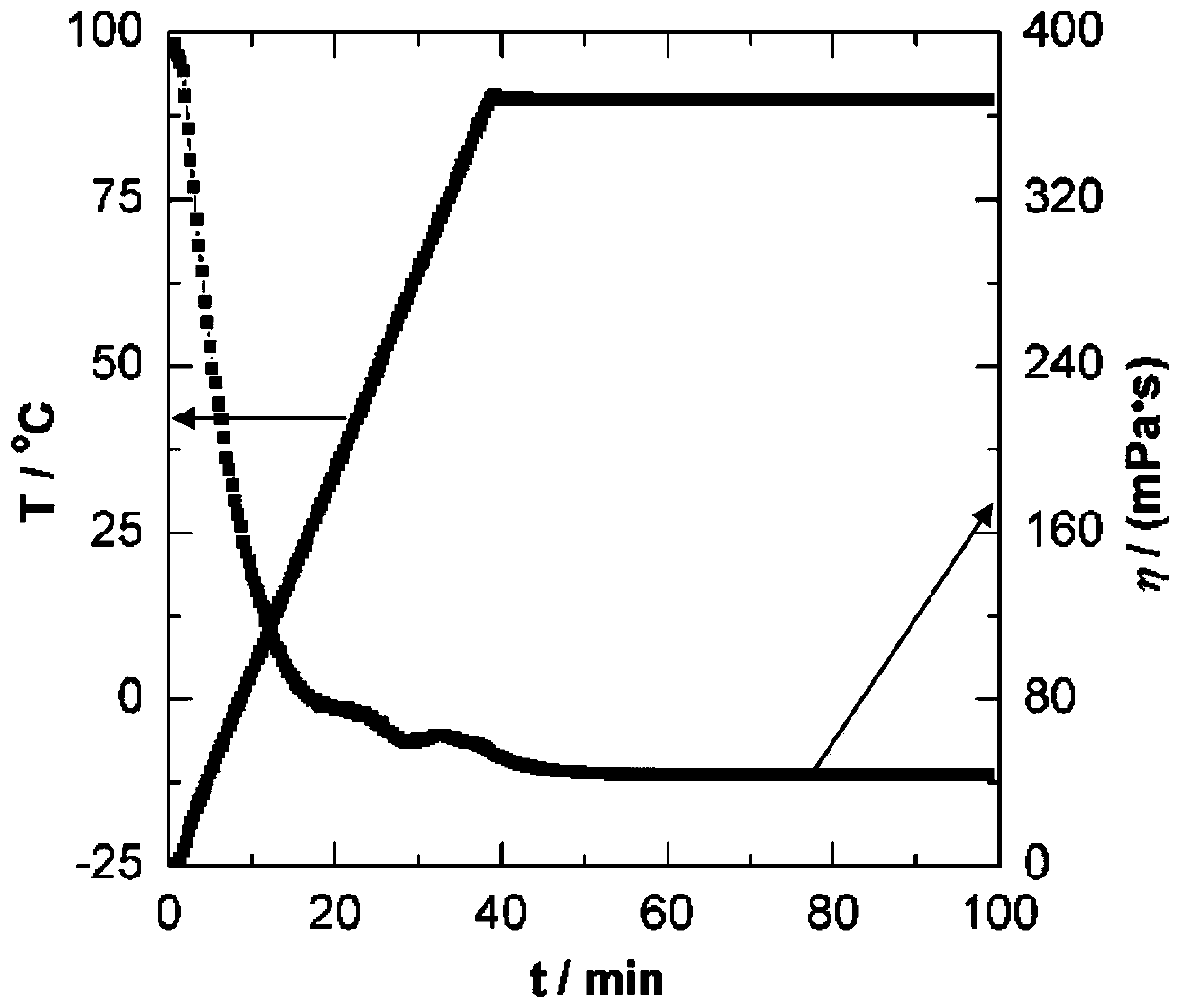

[0056] The rheological properties of the prepared solutions were tested using a rotational rheometer (Anto Paar, MCR 301). At a shear rate of 170s -1 The relationship between the viscosity of the fracturing fluid as a function of temperature and time was tested. Test initial temperature -25°C, at 3°C·min -1 The heating rate is raised to 90°C, and then sheared at a constant temperature for 60 minutes. The test results are shown in image 3 . Depend on image 3 It can be seen that at the initial temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com