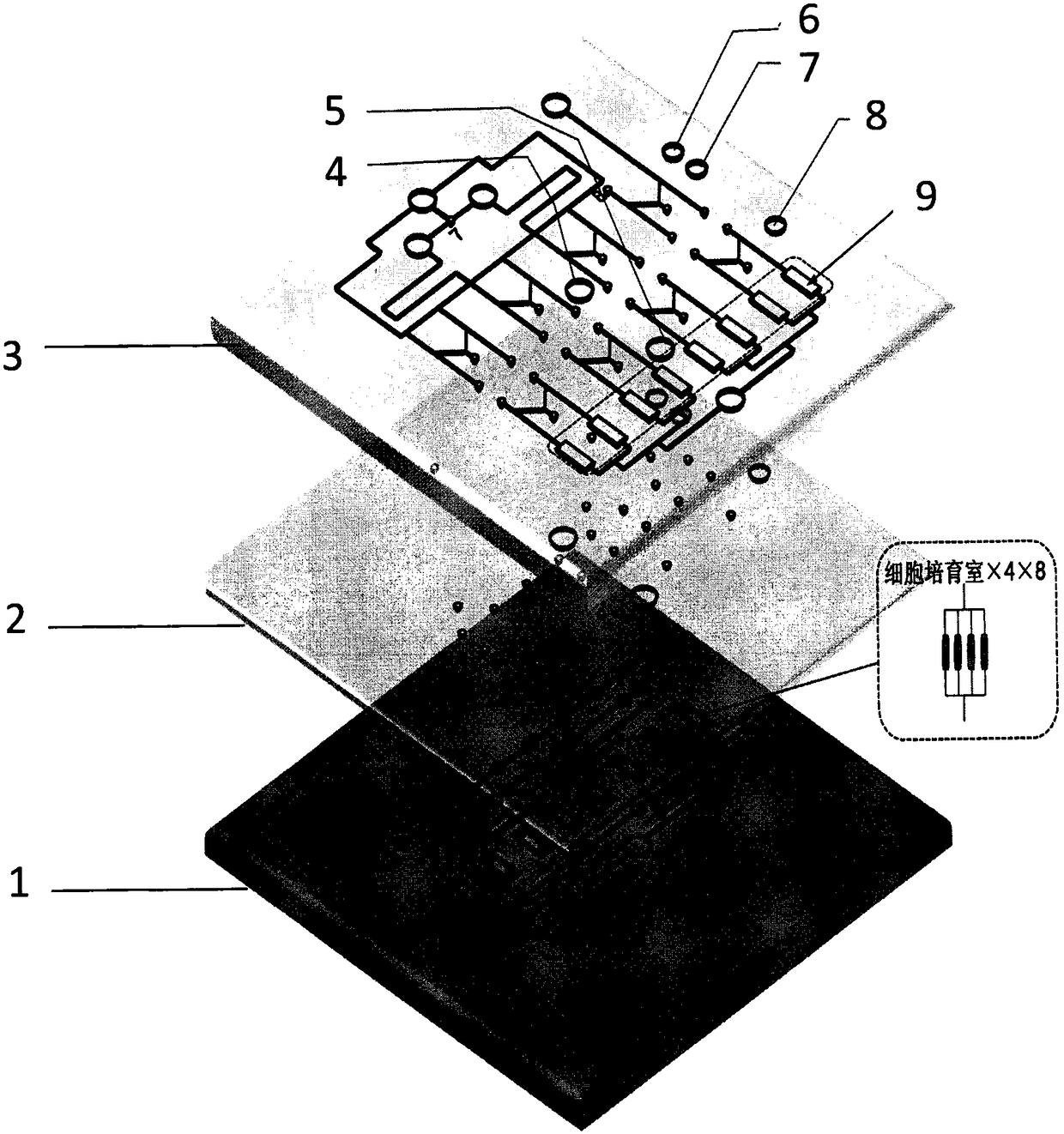

Ocean ecologic toxicology research platform based on microfluidic chip

A microfluidic chip and ecological technology, applied in fluid controllers, biochemical instruments, laboratory containers, etc., can solve the problems of large workload, expensive equipment, complicated pretreatment, etc., and achieve simple operation and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

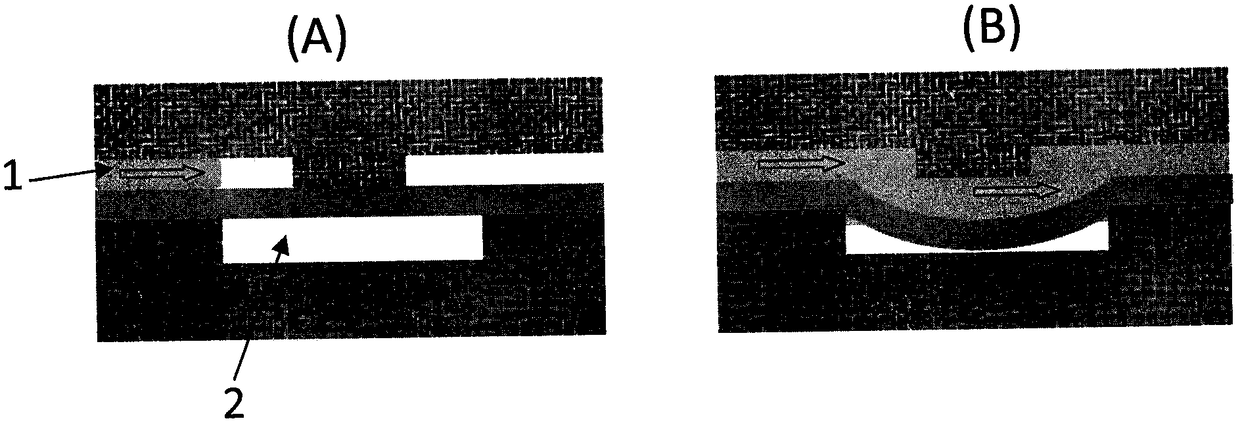

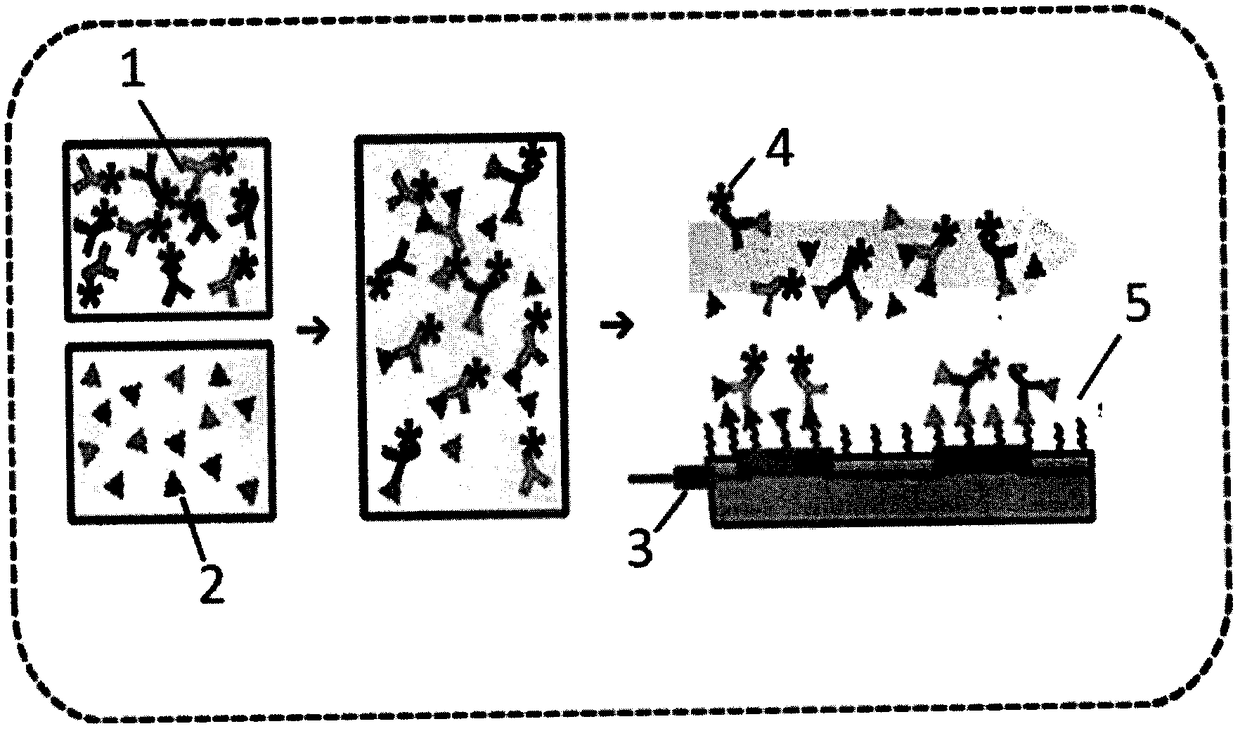

Embodiment 1

[0058] Using the microfluidic chip system designed and produced by the laboratory, the configuration is as follows: Figure 5As shown, marine chlorella was inoculated, and the inoculation density was 1×105cell / mL. The upstream infusion port is externally connected to a micropump, and the blank solution and 10.0 μM heavy metal Cu solution are respectively input, and a single pollution concentration gradient forming unit is used to form eight concentrations from low to high in the downstream, which are 0 μM, 1.4 μM, 2.8 μM, 4.3 μM, 5.7μM, 7.1μM, 8.6μM, 10.0μM; Cu in the pollutant flow path flows into the culture chamber, perfuses into the culture chamber and flows into the waste liquid pool along the waste liquid outflow channel. The microporous membrane at the end of the cultivation chamber retains the marine chlorella in the cultivation chamber. After 72 hours of stimulation, the apparent biological proliferation rate, autochlorophyll fluorescence and FDA fluorescence of mari...

Embodiment 2

[0060] Using the microfluidic chip system designed and produced by the laboratory, the configuration is as follows: Figure 5 As shown, the subcardioid algae were inoculated, and the inoculation density was 1×106cell / mL. The upstream infusion port is externally connected to a micropump, and the blank solution and 4.41 μM heavy metal Cu solution are respectively input, and a single pollution concentration gradient forming unit is used to form eight concentrations from low to high in the downstream, which are 0.63, 1.26, 1.89, 2.52, 3.15, and 3.78. , 4.41μmol / L; Cu in the pollutant flow path flows into the culture chamber, perfuses into the culture chamber and flows into the waste liquid pool along the waste liquid outflow channel. The microporous membrane at the end of the cultivation chamber retains the flat algae in the cultivation chamber. After being stimulated for 2 hours, the locomotor activity of P. subtypes was observed, and the corresponding EC50 values were 2.21 μM...

Embodiment 3

[0062] Using the microfluidic chip system designed and produced by the laboratory, the configuration is as follows: Figure 5 As shown, the subcardioid algae were inoculated, and the inoculation density was 1×106cell / mL. The upstream infusion port is externally connected to a micropump, and the blank solution and 9.03mmol organic pollutant phenol solution are respectively input, and a single pollution concentration gradient forming unit is used to form eight concentrations from low to high in the downstream, which are 0, 1.29, 2.58, 3.87, and 5.16 respectively. , 6.45, 7.74, 9.03mmol / L; phenol in the pollutant flow path flows into the culture chamber, perfuses into the culture chamber and flows into the waste liquid pool along the waste liquid outflow channel. The microporous membrane at the end of the cultivation chamber traps the subnovinal flat algae in the cultivation chamber. After being stimulated for 2 hours, the locomotor activity of P. subtypes was observed, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com