A bridge inspection vehicle slewing device

A technology of bridge inspection vehicle and slewing device, which is applied in the direction of bridges, bridge construction, bridge parts, etc. It can solve the problems of low reliability of rotation connection, damage of slewing bearing, shaking of lower truss, etc., and achieves simple structure, reduced bearing pressure, and easy Achieved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

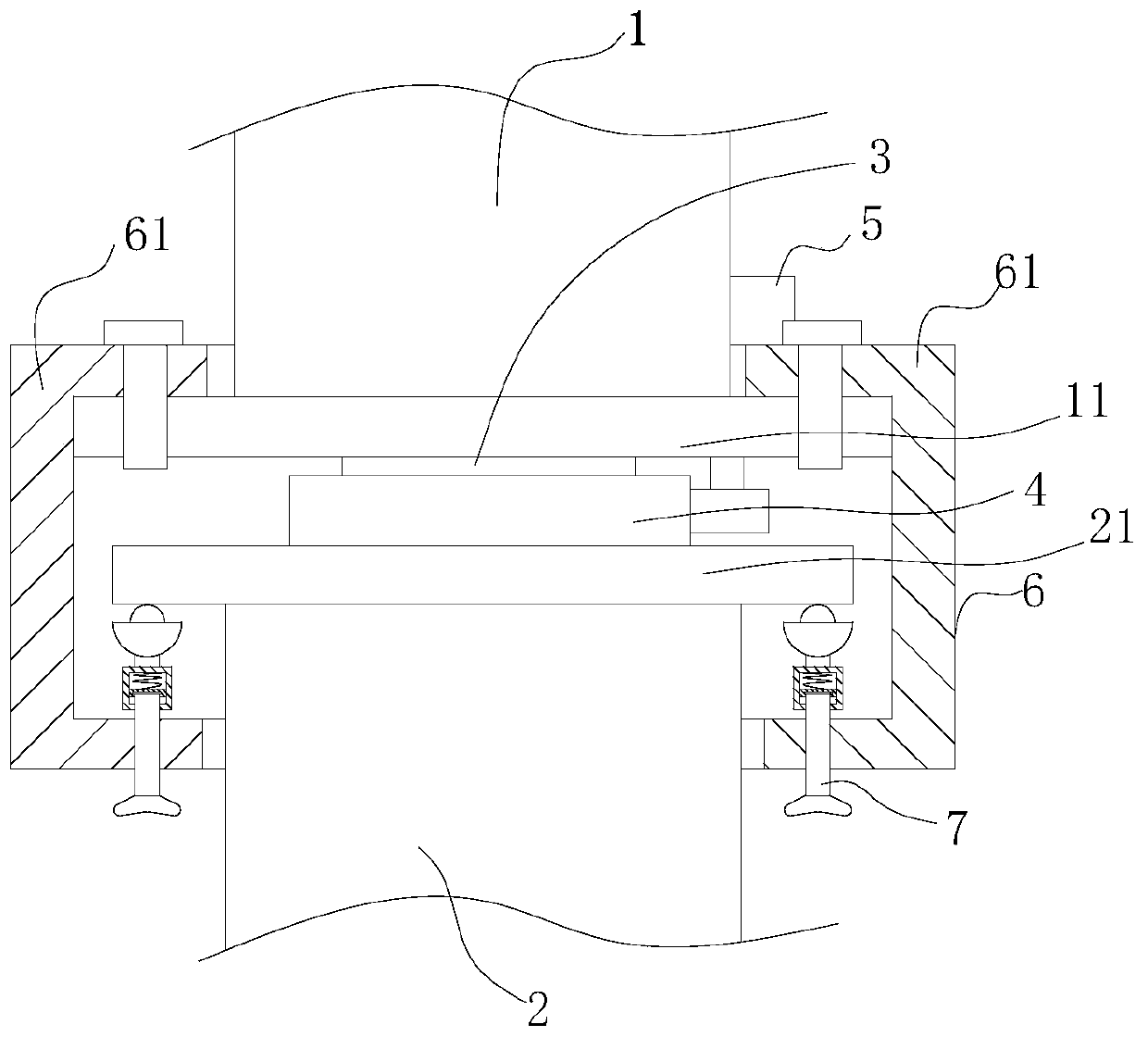

[0025] refer to figure 1 , the swivel device of the bridge inspection vehicle includes: an upper truss 1, a lower truss 2 and a driving mechanism 5, a bearing seat 3 arranged below the upper truss 1, a revolving base 4 arranged above the lower truss 2, the revolving base 4 and the bearing seat 3 Through the connection of the slewing bearing arranged in the bearing seat 3, the drive mechanism 5 is connected with the lower truss 2 in transmission to drive the lower truss 2 to rotate. In addition, the swivel device of the bridge inspection vehicle also includes: a fixed sleeve 6 and a plurality of support assemblies 7;

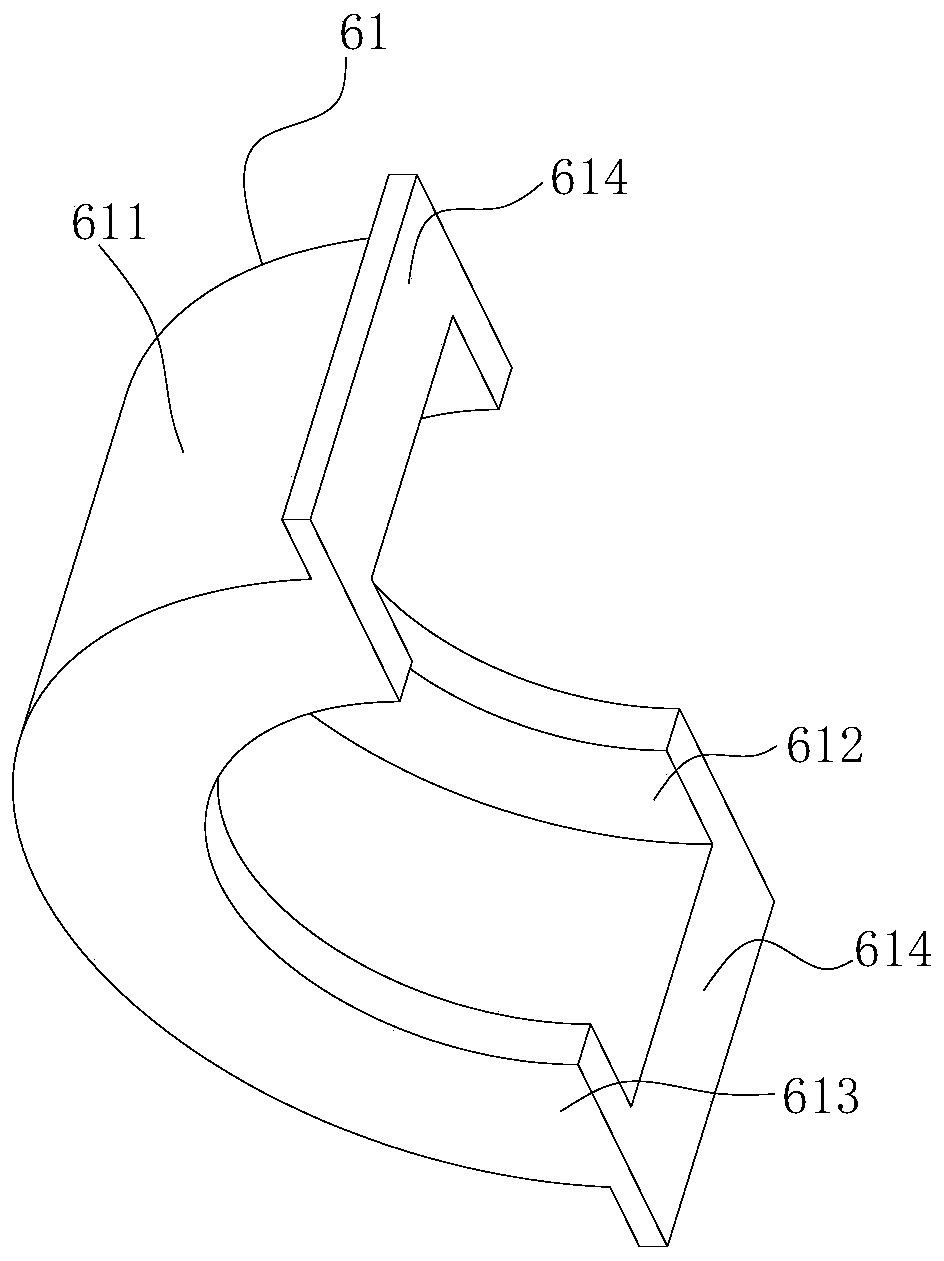

[0026] refer to figure 1 and image 3 , the upper truss 1 is provided with a mounting plate 11, the lower truss 2 is provided with a support plate 21, and the lower surface of the support plate 21 is a plane; the fixed sleeve 6 includes two semi-cylindrical parts 61, and the semi-cylindrical part 61 includes: semi-cylindrical 611 , a semi-annular first protrus...

Embodiment 2

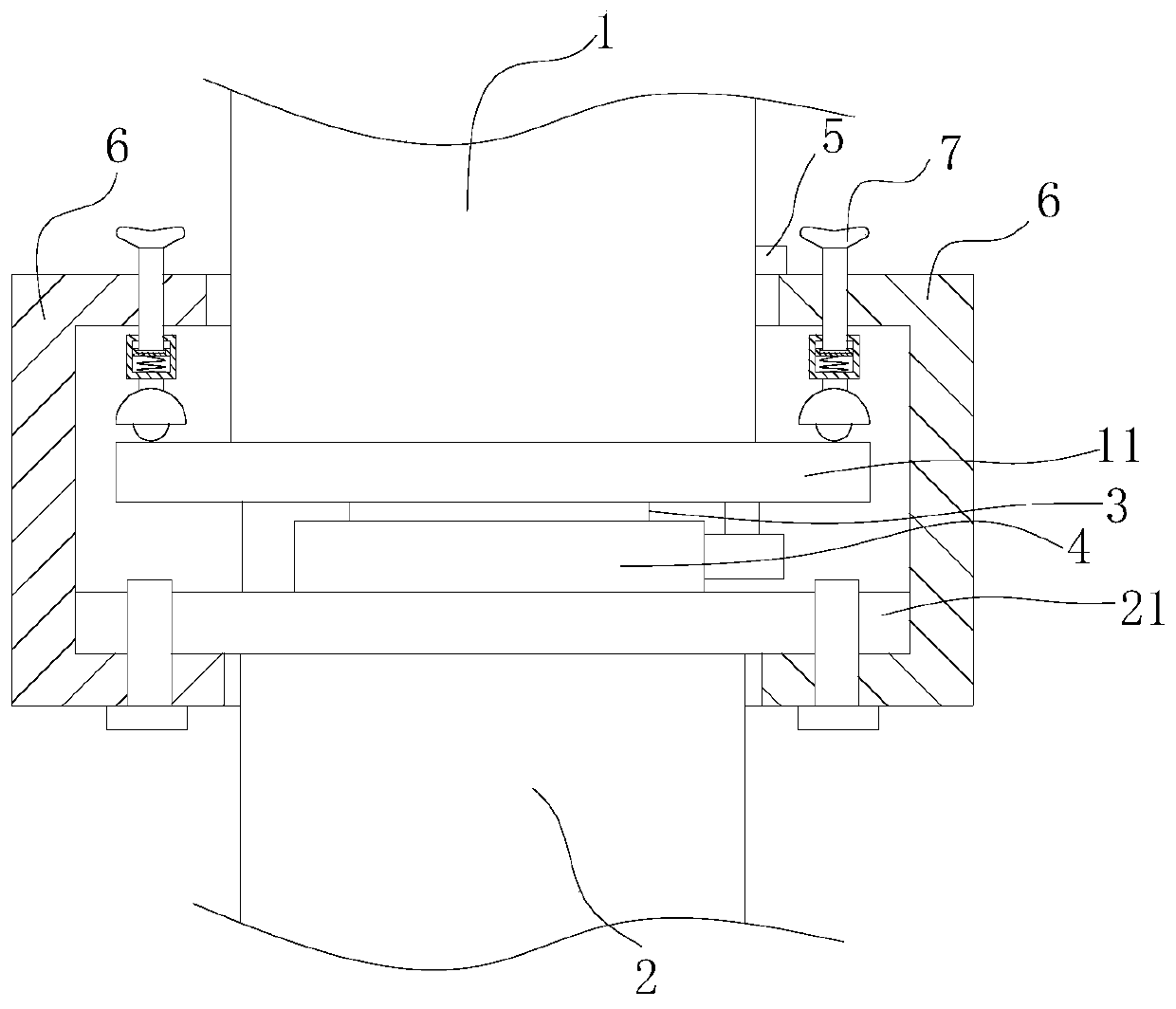

[0036] refer to figure 2 , the swivel device of the bridge inspection vehicle includes: an upper truss 1, a lower truss 2 and a driving mechanism 5, a bearing seat 3 arranged below the upper truss 1, a revolving base 4 arranged above the lower truss 2, the revolving base 4 and the bearing seat 3 Through the connection of the slewing bearing arranged in the bearing seat 3, the drive mechanism 5 is connected with the lower truss 2 in transmission to drive the lower truss 2 to rotate. In addition, the swivel device of the bridge inspection vehicle also includes: a fixed sleeve 6 and a plurality of support assemblies 7;

[0037] The upper truss 1 is provided with a mounting plate 11, and the lower truss 2 is provided with a support plate 21. The upper surface of the mounting plate 11 is a plane; the fixing sleeve 6 includes two semi-cylindrical parts 61, and the semi-cylindrical part 61 includes: a semi-cylindrical cylinder 611, A semi-annular first protrusion 612 disposed at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com