Water hammer eliminating tank and water hammer eliminating method

A water hammer and tank technology, applied in the direction of pipes/pipe joints/pipes, mechanical equipment, pipe components, etc., can solve problems such as damage to main water pipe equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

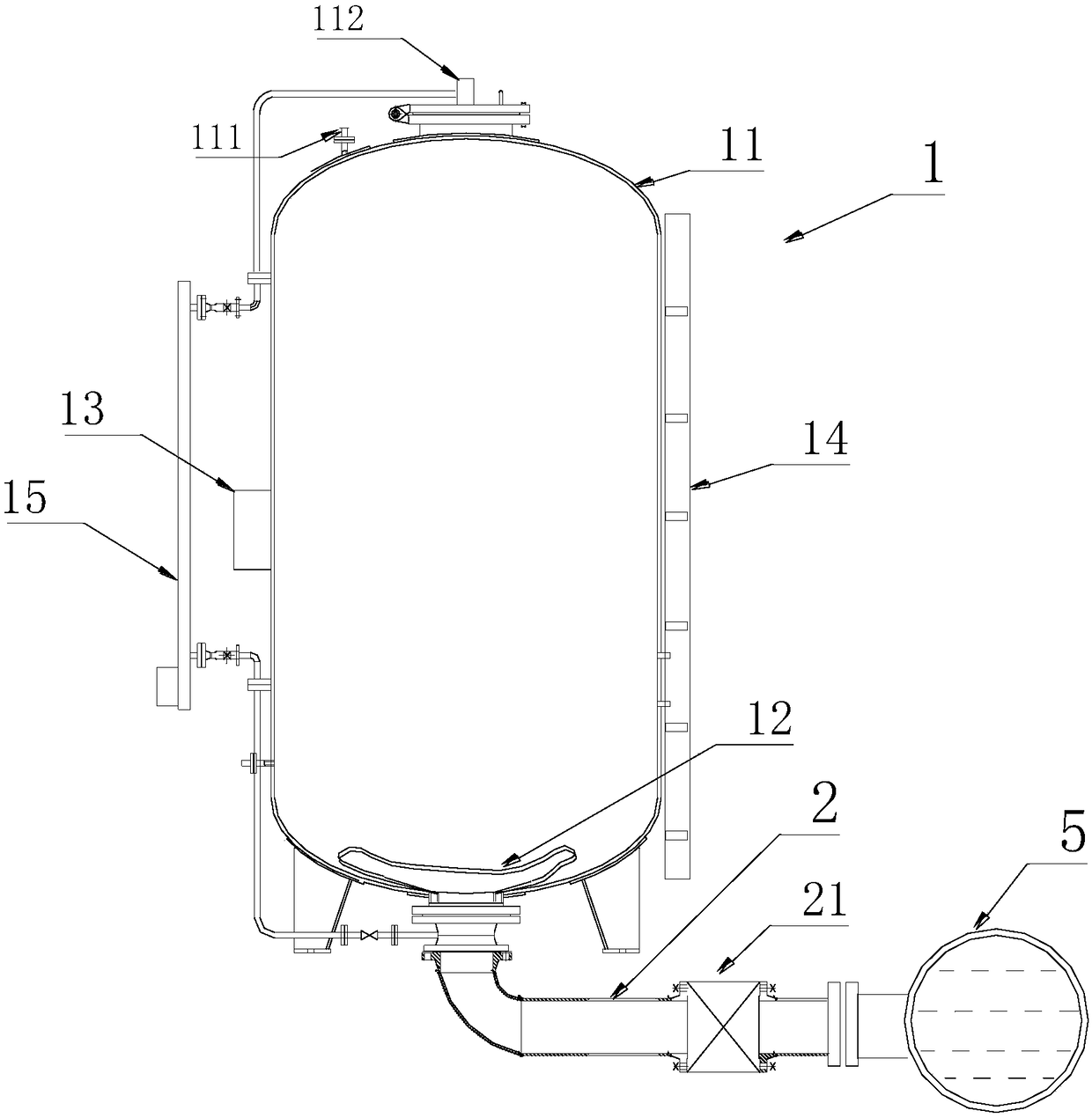

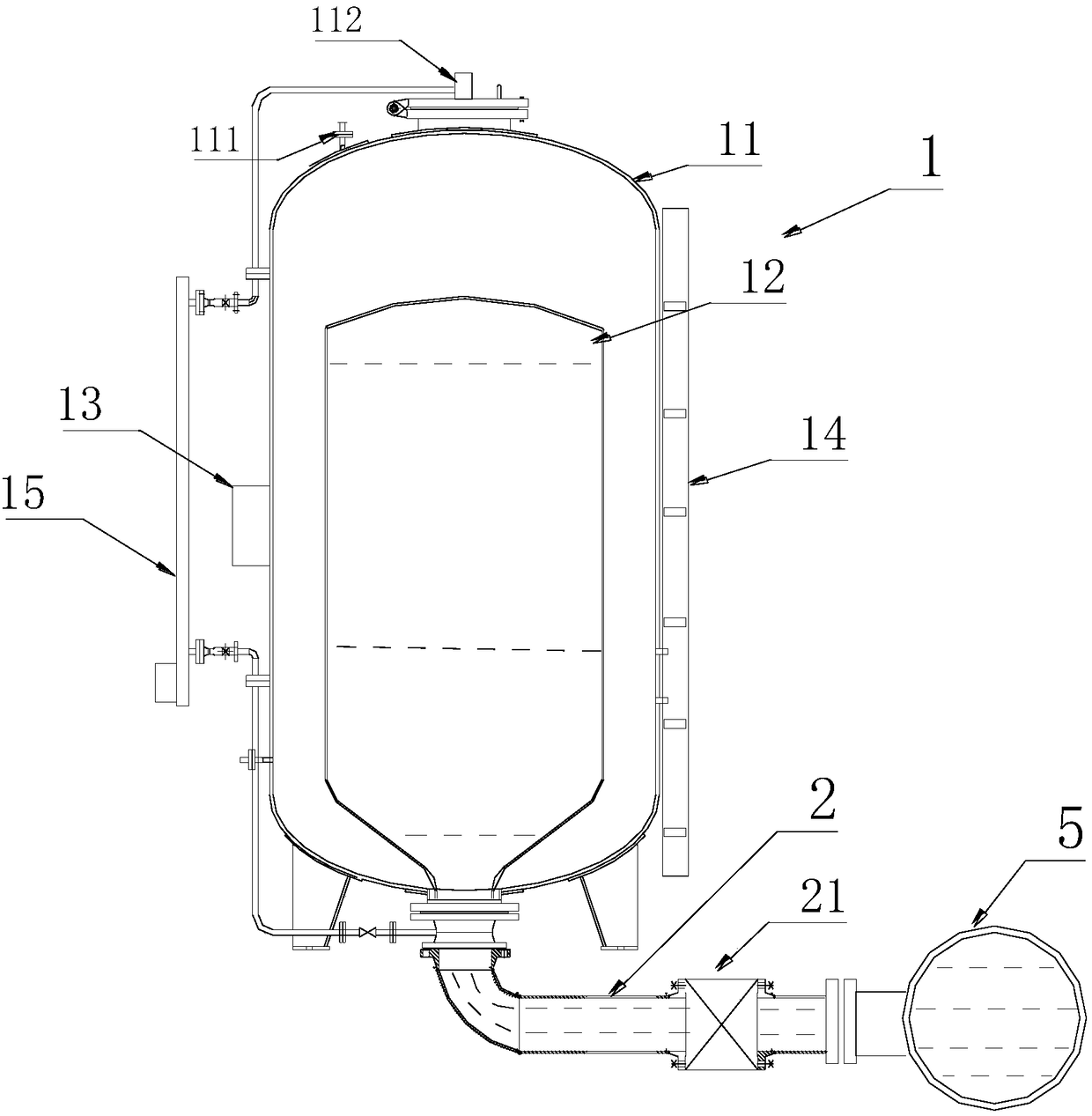

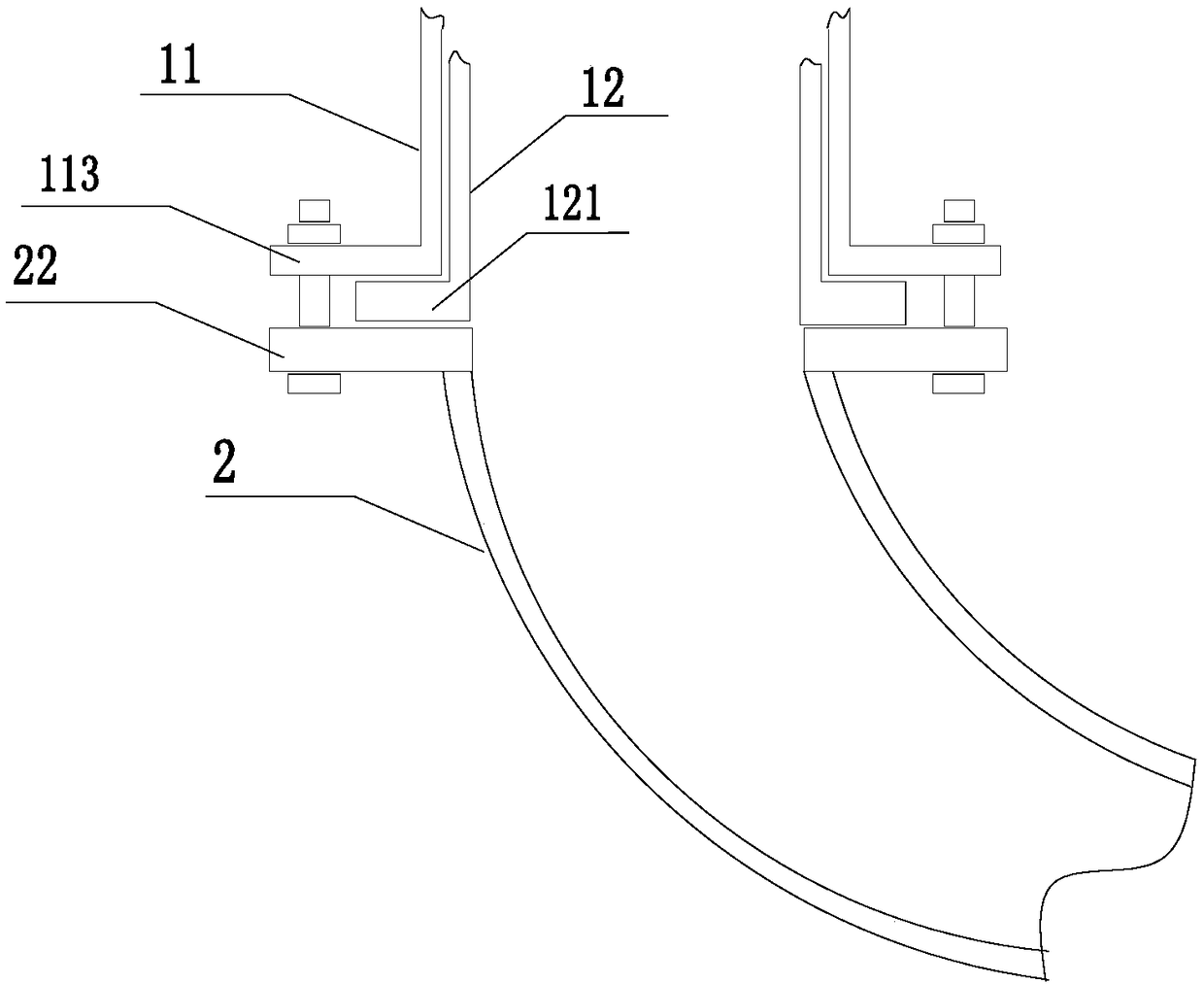

[0026] Such as figure 1 and figure 2 A water hammer elimination tank is shown, the water hammer elimination tank includes a tank body 1 and a connecting pipe 2, the tank body 1 includes an outer shell 11 and an expandable liner 12 arranged in the outer shell 11, and the outer shell 11 is provided with Inflatable valve 111 and pressure relief valve 112, the opening of the expandable liner 12 is concentrically sleeved in the opening of the shell 11, the opening of the expandable liner 12 is in sealing communication with one end of the connecting pipe 2 and the end of the connecting pipe 2 is sealed The opening of the shell 11 is pre-filled with gas between the shell 11 and the expandable liner 12, and the other end of the connecting pipe 2 communicates with the main water pipe 5. The material of the expandable liner 12 is preferably rubber, and the air pipe of the air compressor Air pressure is charged into the tank body 1 through the inflation valve 111, and when the air pres...

Embodiment 2

[0039]This embodiment is basically the same as Embodiment 1, the difference is that the water hammer elimination tank also includes a control system 3 and an air supply mechanism 4, the control system 3 includes a controller 31 and an operation panel 32, and the air supply mechanism 4 includes an air Compressor 41, air pipe 42 and solenoid valve 43, one end of air pipe 42 is connected to the air outlet of air compressor 41, the other end of air pipe 42 is connected to the inflation valve 111, and solenoid valve 43 is installed on air pipe 42 , the air compressor 41 and the liquid level detection device 15 are respectively connected to the controller 31, there will be a small amount of gas leakage in the tank body 1 for about 3 months, the air pressure value will decrease, and the decrease in the air pressure value will cause the water pressure to decrease. If the air pressure is greater than the air pressure, the main water pipe fills the expandable inner tank 12 with water, ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com