Method and device for comprehensively evaluating coating protection performance

A protection performance and comprehensive evaluation technology, which is applied in the comprehensive evaluation of coating protection performance and equipment fields, to achieve the effect of enhancing credibility, improving scientificity and rationality, and ensuring accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this example, taking the coating system of sulfuric acid anodization + TB06-9 + TS70-60 as an example, the evaluation method of coating protection performance is described in detail.

[0041] Coating test information: The outdoor air exposure test of the offshore platform was continuously carried out for 4 years by using a rectangular flat sample coated with sulfuric acid anodization + TB06-9 + TS70-60 multi-layer coating system.

[0042] The specific steps for the evaluation of the protective performance of the coating:

[0043] Step 1: According to the coating application occasion (marine atmospheric environment), select the seven items of powdering, cracking, blistering, rusting, peeling, thickness loss and adhesion as the evaluation index of coating protection performance, and obtain the selected The measured value of the evaluation index;

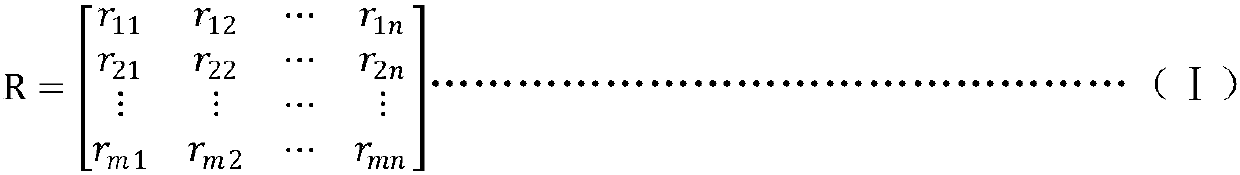

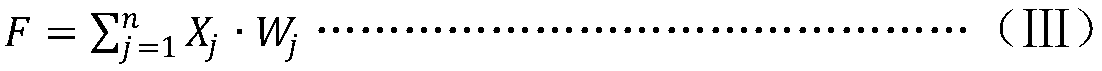

[0044] Step 2: Carry out dimensionless processing on the evaluation indicators in step 1. Specifically, use the 0-5 level ...

Embodiment 2

[0061] A coating protection performance evaluation equipment, including a computer, the computer includes a memory, a processor, and a computer program stored on the memory and operable on the processor, wherein the processor implements the following steps when executing the program :

[0062] Step A: Select the evaluation index, input the measured value of the evaluation index, the computer processor receives the input measured value of the evaluation index and compares it with the stored data in the database, and outputs the index evaluation value X j ; The evaluation index includes gloss, color difference, chalking, cracking, blistering, rusting, peeling, thickness loss and / or adhesion drop rate;

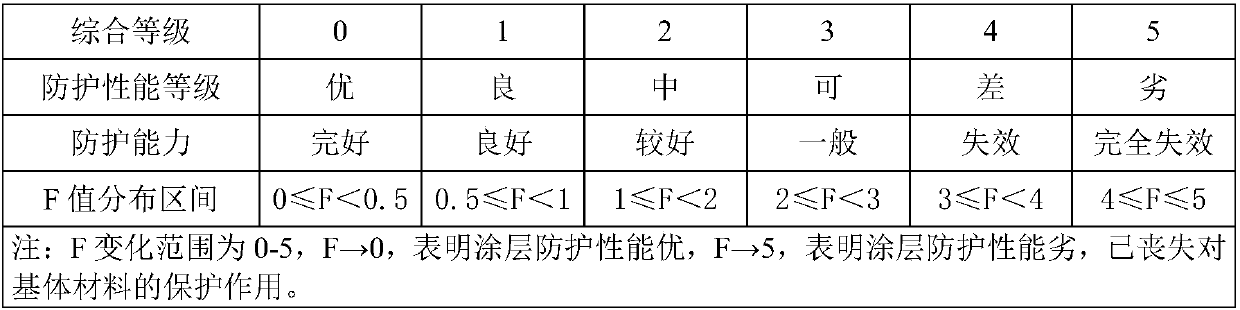

[0063] The stored data in the database includes Table 1, Table 2, the grade classification standards for gloss, color difference, chalking, cracking, blistering, rust, and peeling in GB / T 1766-2008, and the coating in Table 3 Comprehensive grade evaluation standard of protective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com