Spring operating mechanism and circuit breaker

A technology of operating mechanism and circuit breaker, which is applied in contact driving mechanism, protective switch operation/release mechanism, contact vibration/shock damping, etc. It can solve problems such as shortening and prolonging curve travel, damage buffer components, etc., and achieve improvement Effects of mechanical characteristics, reduction of lateral impact, and parameter stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

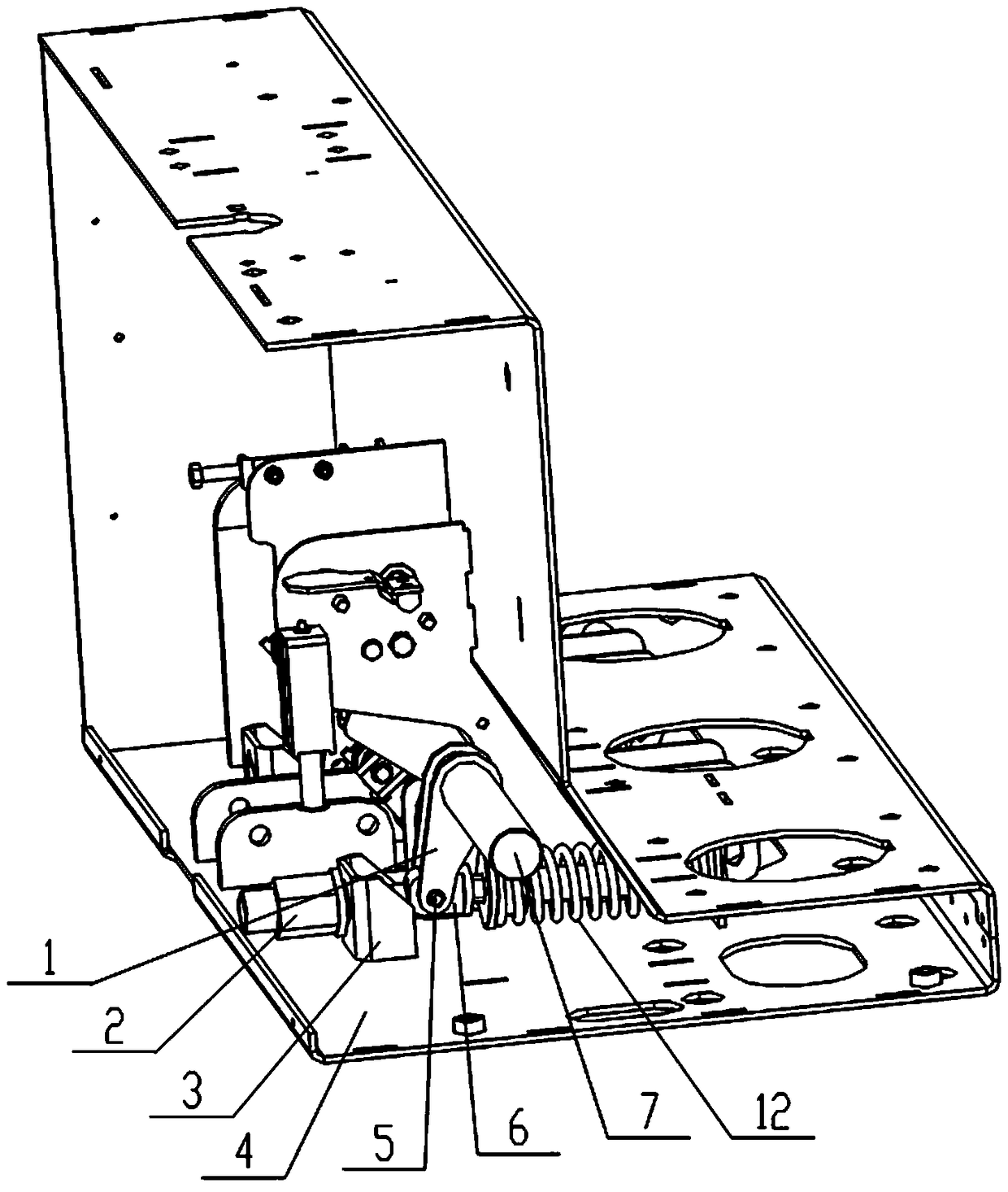

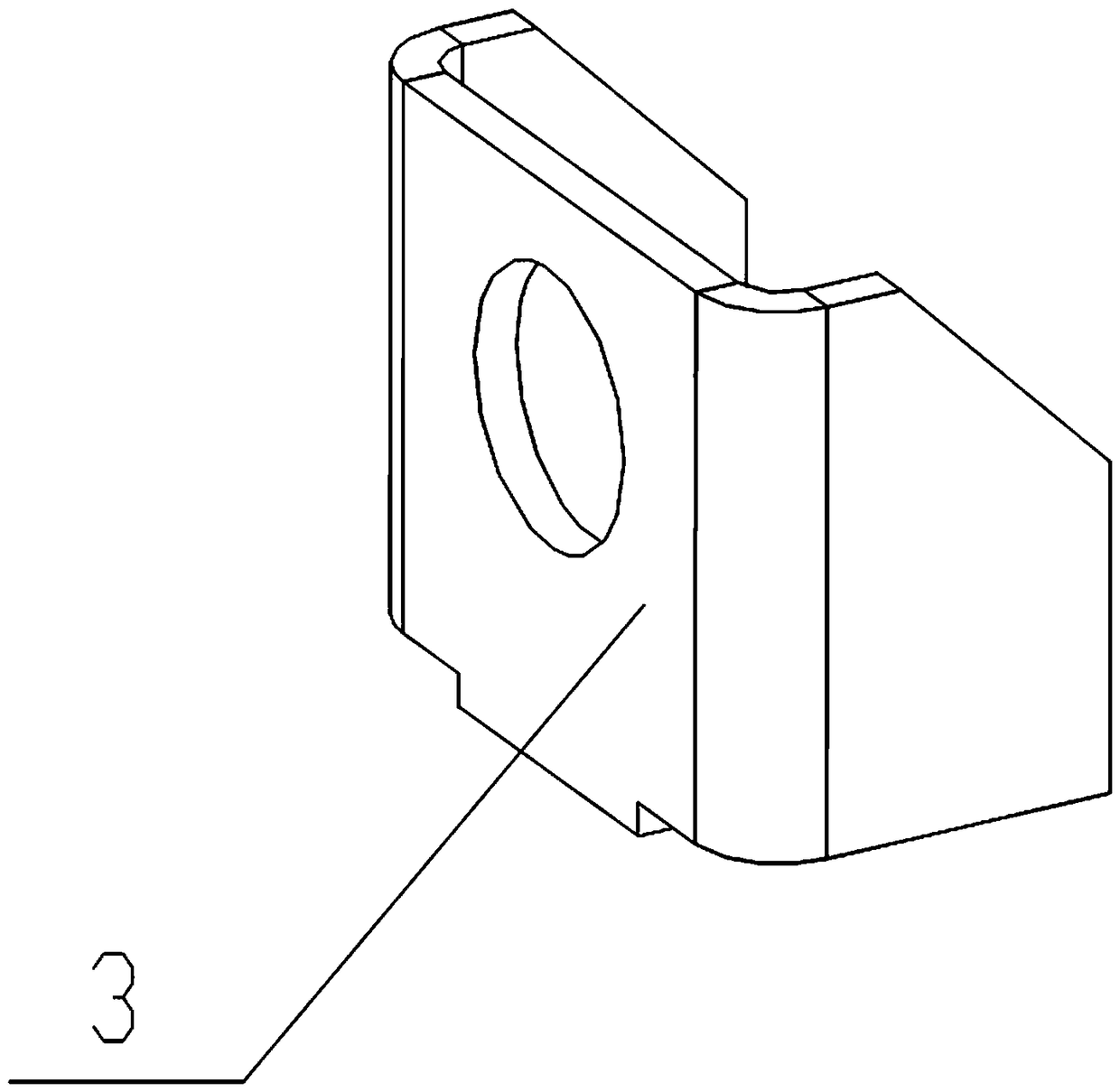

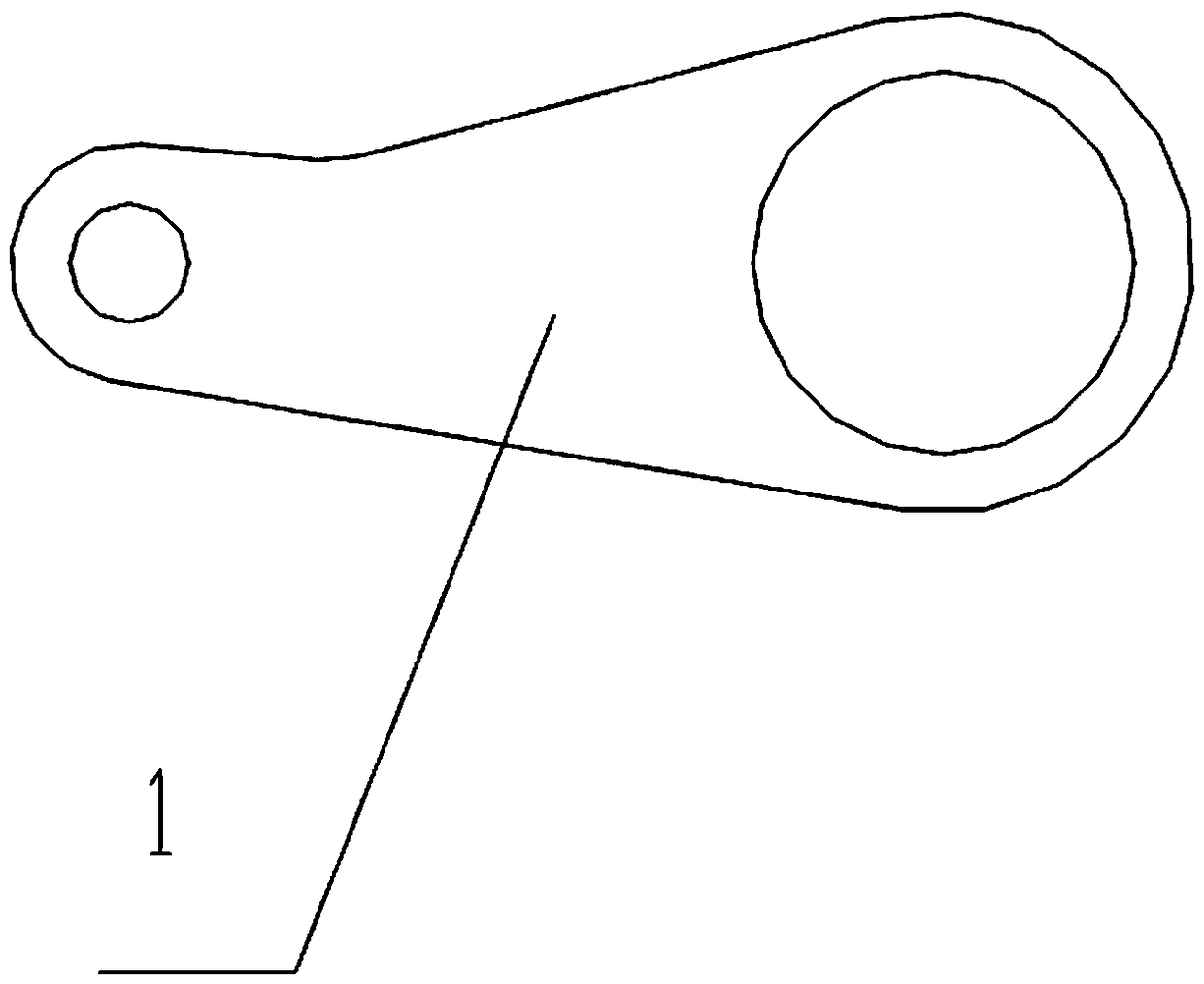

[0027] Specific embodiments of the circuit breaker of the present invention, such as Figure 4 to Figure 6 As shown, it includes contacts (not shown in the figure) and a spring operating mechanism. The gate spring 12 is installed on the spring mandrel 13, one end of the spring mandrel 13 is connected with the base 4, and the other end is provided with a spring seat 6, the spring seat 6 is connected with the opening toggle arm 8 through the pin shaft 5, and the spring seat 6 is located at Between the two opening levers 8, the opening lever 8 is provided with a long hole 11, the pin shaft 5 can move in the long hole 11, and the position of the pin shaft 5 relative to the spring seat 6 is fixed. The mechanism also includes a buffer mounting plate 9 welded on the base 4, the buffer mounting plate 9 is provided with a guide slideway that cooperates with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com