Pixel structure, mask and display device

A technology of pixel structure and mask plate, which is applied in the direction of vacuum evaporation plating, coating, electric solid device, etc., can solve the problems of FMM process implementation difficulty and cannot meet the high PPI development requirements of OLED display devices, and achieve the reduction of manufacturing process And the difficulty of the evaporation process, the effect of good display effect and uniform color distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

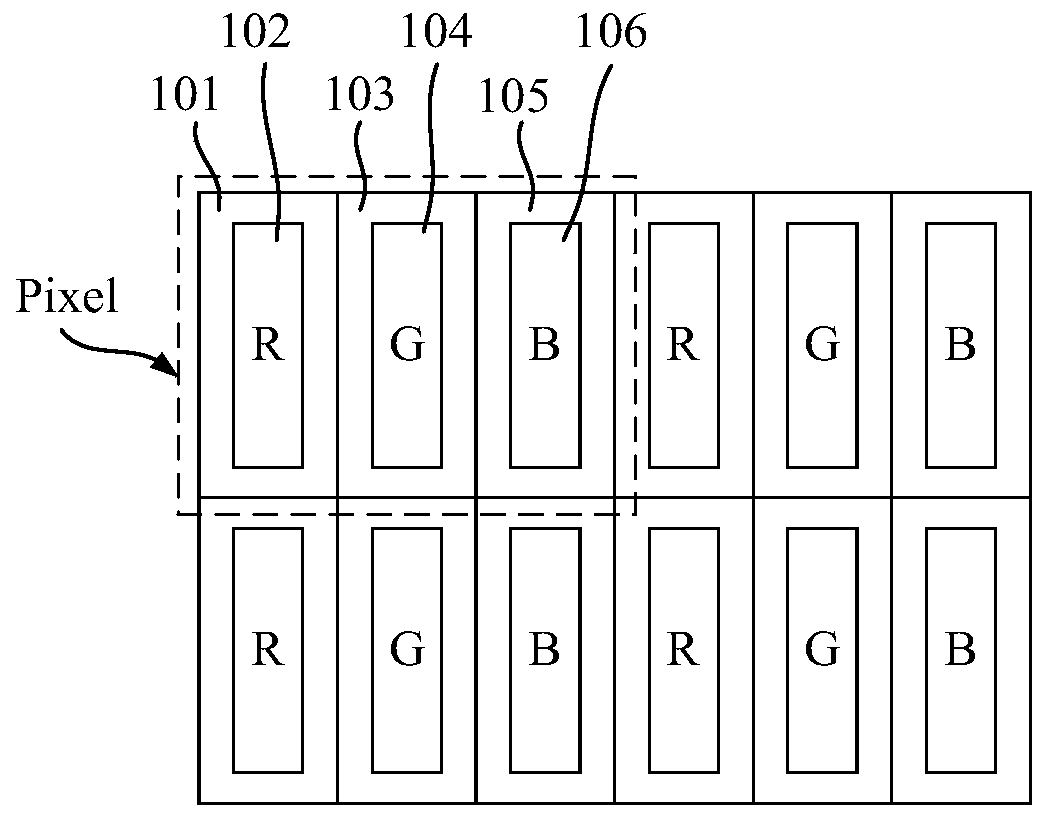

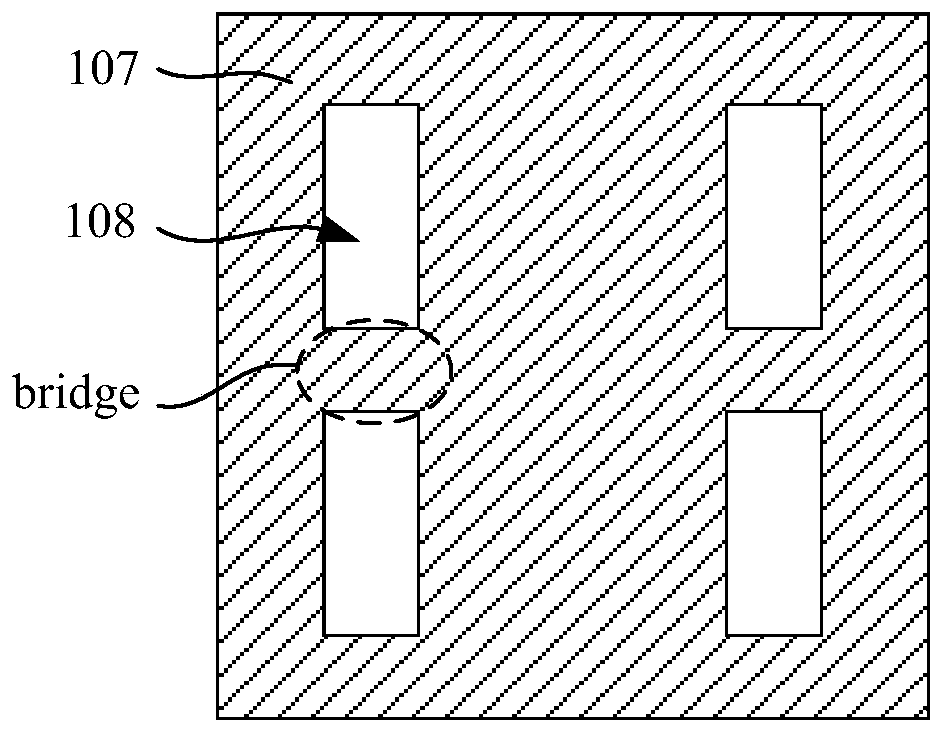

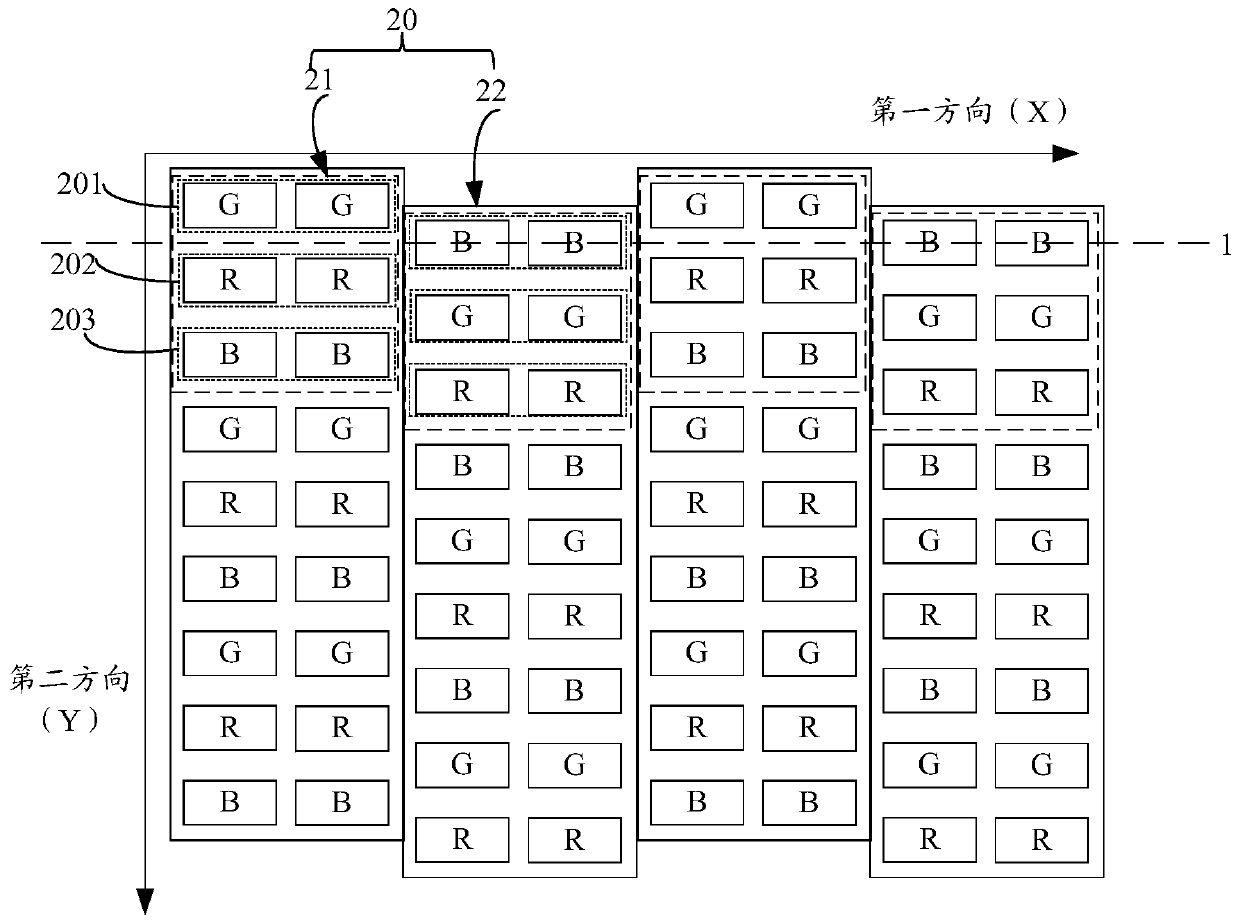

[0026] After research, the applicant found that the traditional RGB pixel structure can no longer meet the requirements of high PPI display effect of the product. Based on this, the present invention provides a pixel structure, including a plurality of pixel groups arranged in an array, each of the pixel groups includes a first pixel group and a second pixel group that are adjacently arranged and mutually misaligned, and the first pixel group Both the second pixel group and the second pixel group include sub-pixel groups with three different colors, and the arrangement orders of the three different-color sub-pixel groups in the first pixel group and the second pixel group are different; each sub-pixel group includes At least two sub-pixels of the same color are respectively adjacently arranged. In this pixel structure, the first pixel group and the second pixel group of the pixel group are adjacent and dislocated, and the two sub-pixels of the same color in each pixel group ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com