Rotor, motor comprising rotor and power device comprising motor

A technology for power devices and rotors, applied in the direction of electromechanical devices, magnetic circuit rotating parts, electric components, etc., can solve the problems of increased motor torque ripple, decreased reluctance torque, and large reluctance, so as to reduce the rotational speed. Torque ripple, the effect of increasing the reluctance torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

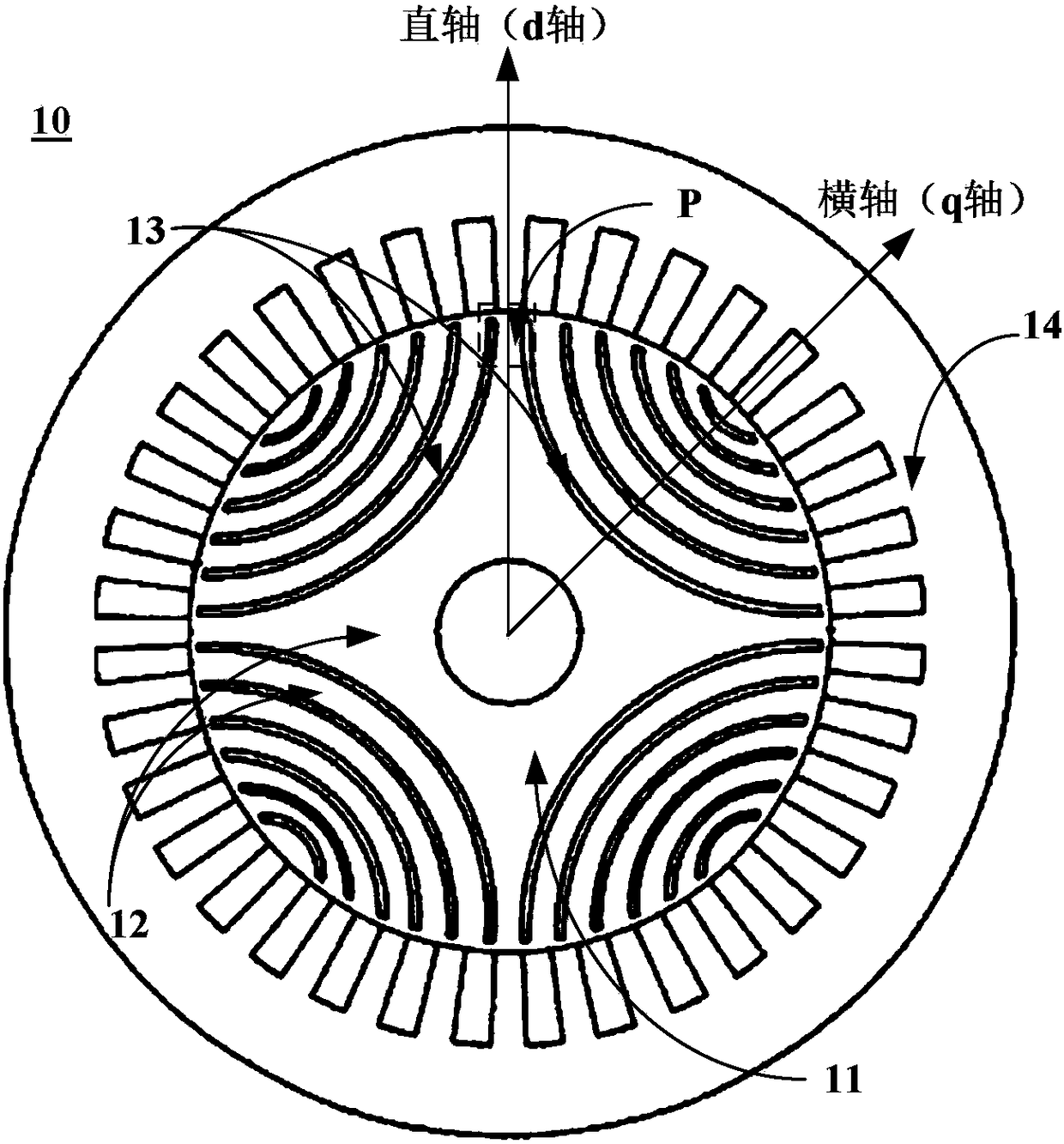

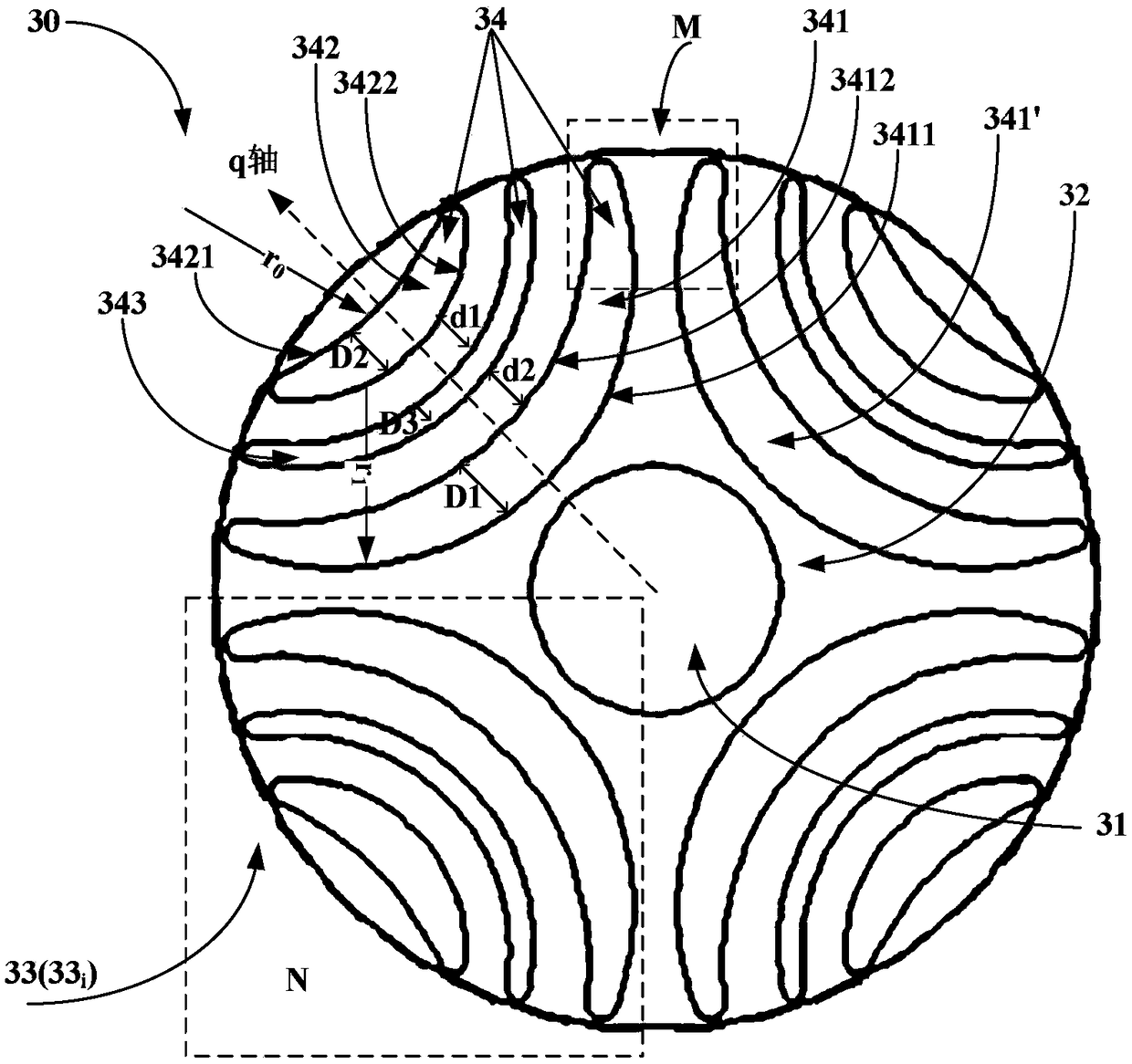

[0035] An embodiment of the present invention provides a rotor, image 3 It is a plan view of the rotor of Example 1 of the present invention. Since the rotor is composed of electromagnetic steel plates laminated in the axial direction, it can be seen from image 3 What you see is the axial side of an electromagnetic steel plate.

[0036] Such as image 3 As shown, the rotor 30 is located on the outer periphery of the rotating shaft 31 of the motor (not shown), and rotates together with the rotating shaft 31. The rotor 30 is composed of electromagnetic steel plates 32 laminated in the axial direction. The through-hole group 33 of the steel plate 32, the through-hole group 33 has a plurality of through-holes 34, and the plurality of through-holes 34 have an imaginary line extending in the radial direction as a center line (such as image 3 The shown q-axis) is in the shape of an arc extending to both sides of the q-axis and radially outward, and a plurality of through holes 3...

Embodiment 2

[0060] The embodiment of the present invention also provides a motor, Figure 6 It is an exploded schematic diagram of the motor of Embodiment 2 of the present invention.

[0061] Such as Figure 6 As shown, the motor 60 can have a rotating shaft 31, and the rotating shaft 31 extends along the central axis; a rotor 30, which is the rotor as described in Embodiment 1, and the rotor 30 rotates around the rotating shaft 31; and a stator 62, assembled , the stator 62 is opposed to the rotor 30 in the radial direction. Since the structure of the rotor 30 has been described in detail in Embodiment 1, its content is included here, and will not be repeated here.

[0062] In this embodiment, in order to further reduce the torque ripple, there is a certain corresponding relationship between the slots of the stator of the motor and the through holes of the electromagnetic steel plate constituting the rotor.

[0063] Figure 7 It is a top view of a part of the motor of Embodiment 2 of...

Embodiment 3

[0068] The embodiment of the present invention also provides a power device, which has the motor described in Embodiment 2. Since the main structure of the motor has been described in detail in Embodiment 2, its content is included here. I won't repeat them here.

[0069] In this embodiment, as mentioned above, the power device can be any device equipped with a motor, and the motor can be applied to the power transmission of a bulldozer or a crawler belt of a power shovel as a power device.

[0070] According to the structure of the motor of the power plant of this embodiment, the difference in reluctance between the electromagnetic steel sheets constituting the rotor of the motor can be enlarged, thereby increasing the reluctance torque and reducing the torque ripple.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com