Heavy torque logical encoder detection machine

An encoder and logic technology, which is applied in the field of heavy torque logic encoder detection machine, can solve the problems of increased occupied volume, complicated machine, troublesome screening process, etc., and achieves the effect of rapid screening, improved efficiency and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

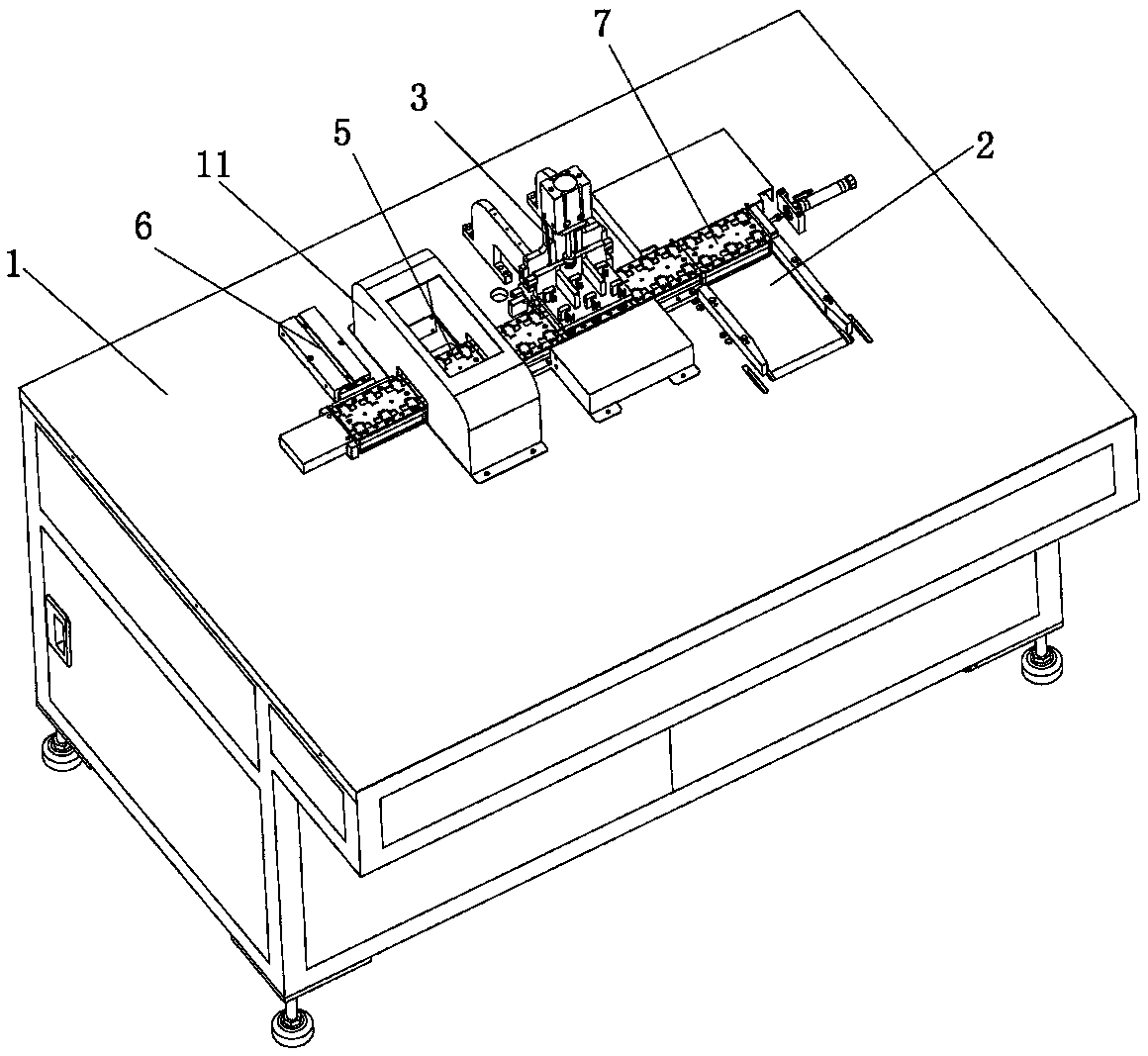

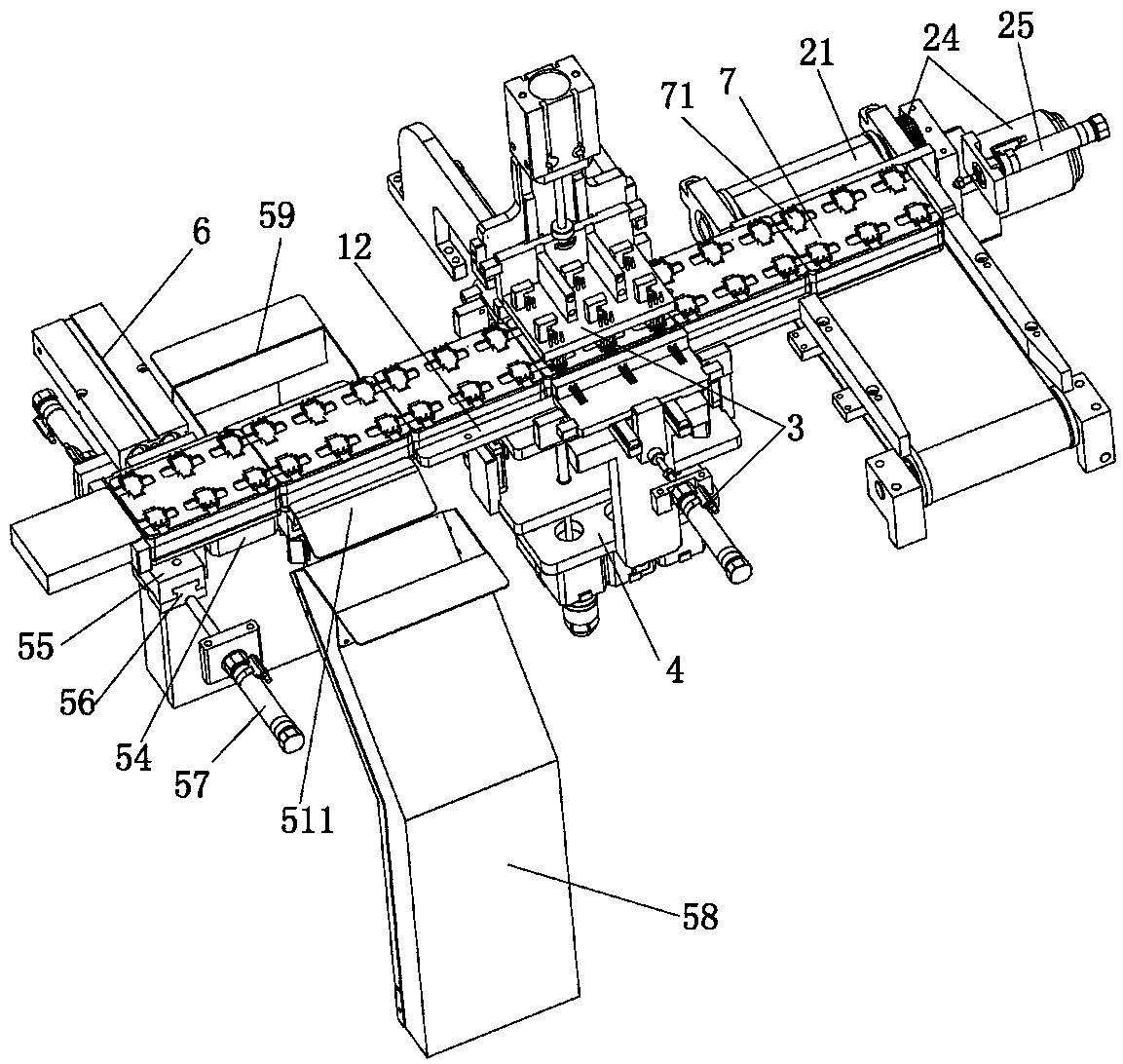

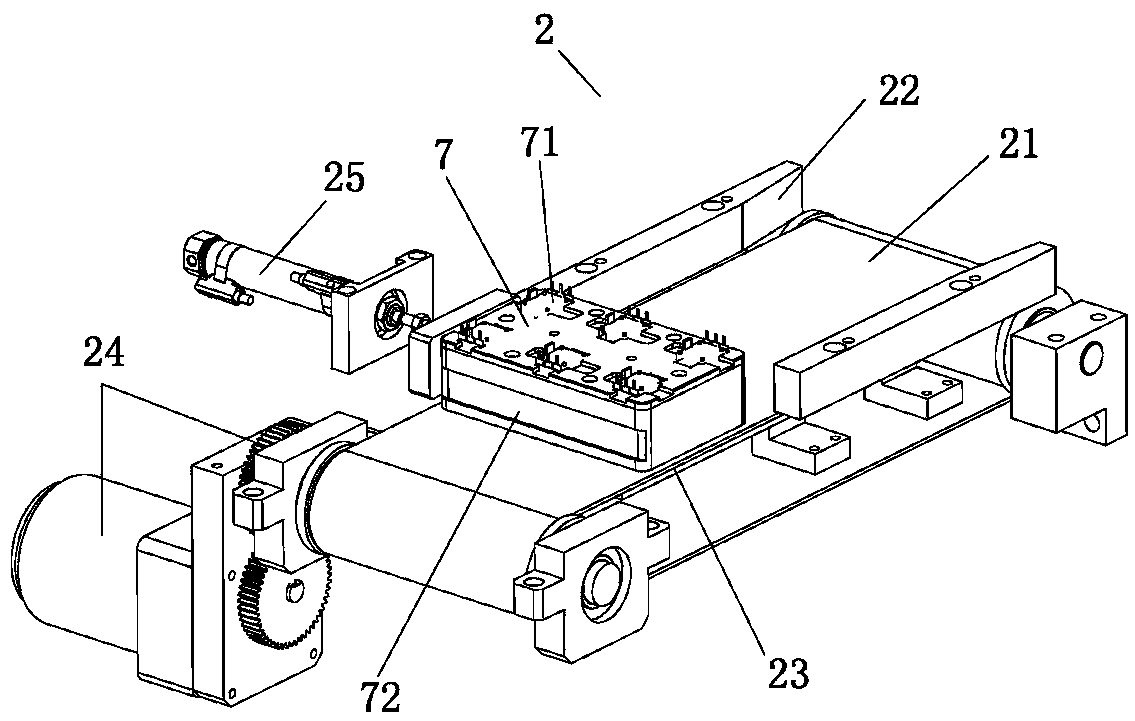

[0020] Refer to attached figure 1 to attach Image 6 The specific implementation manner of the present invention is introduced.

[0021] Such as Figure 1-6 As shown, a heavy torsion logic type encoder 71 detection machine includes a detection platform 1, a linear detection material path arranged on the detection platform 1, and a treatment machine equipped with six encoders 71 to be detected that travel along the linear detection material path. With 7, the detection table 1 is provided with a feeding device 2, a detection device 3, a rotary device 4 for rotating an encoder 71, a rotating shaft 711, and a screening device 5 for screening defective products along the straight line detection channel; the rotary device 4 is arranged on the detection device 3, the detection device 3 includes an upper detection component and a side detection component; the jig 7 is formed with a plurality of placement slots, and the bottom of the placement slots is provided with a through hole fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com