Automatic control technology complete set of plant of tap hole gate valve steel slag-blocking system

A complete set of equipment and tapping hole technology, which is applied in the manufacture of converters, etc., can solve the problems of accuracy and investment timing, unstable slag blocking effect, etc., and achieve the effects of automatic control, reasonable structure, and improved molten steel quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

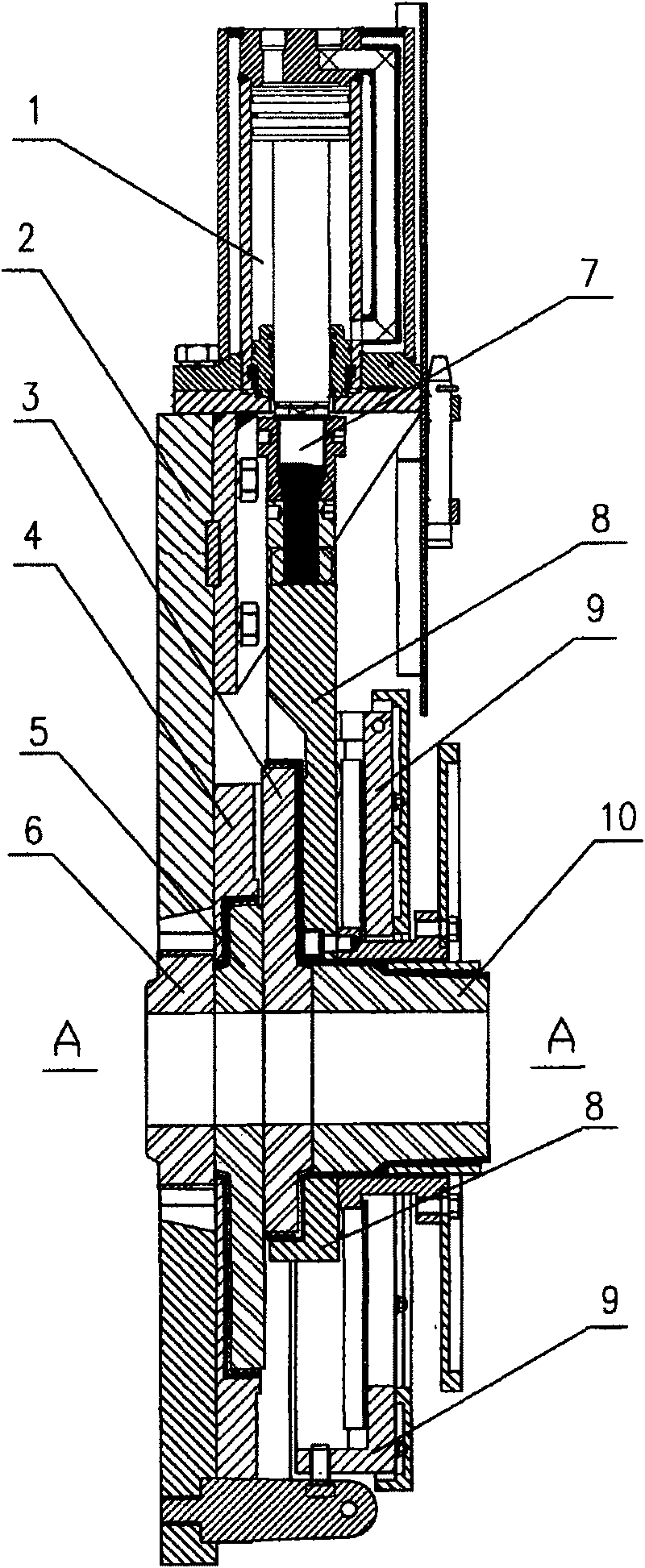

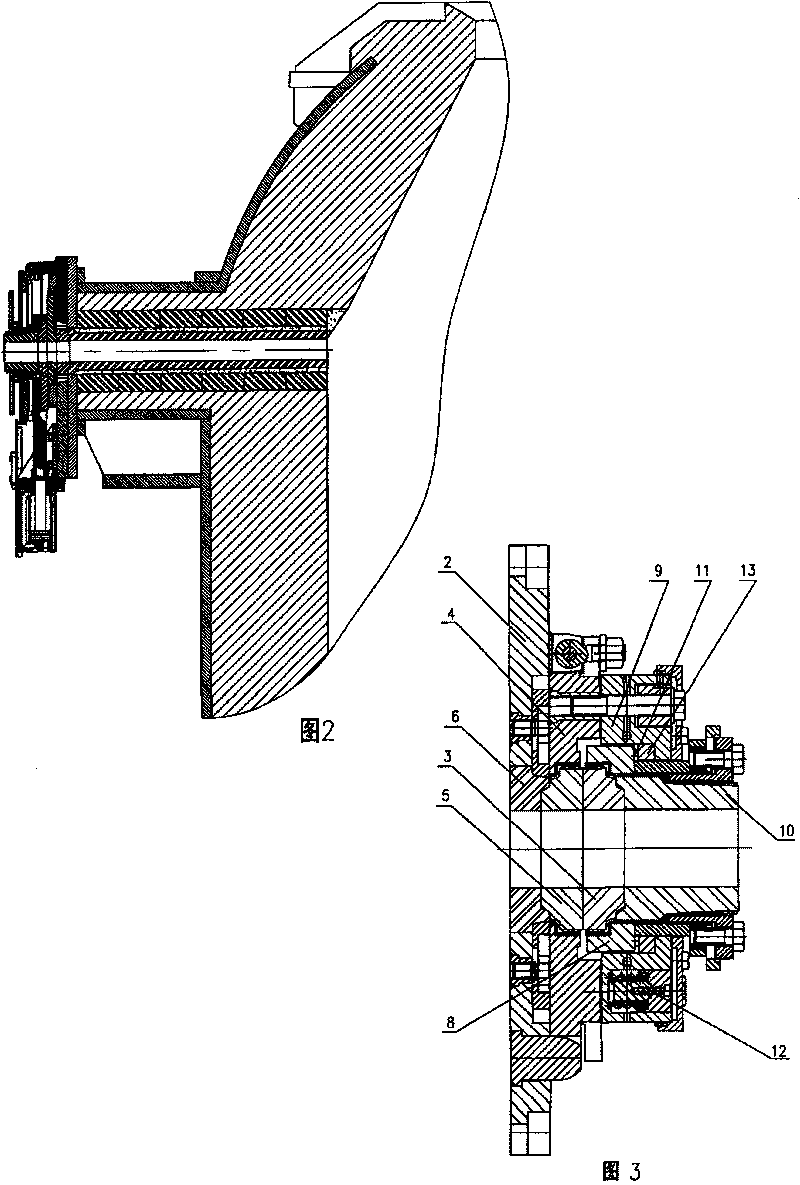

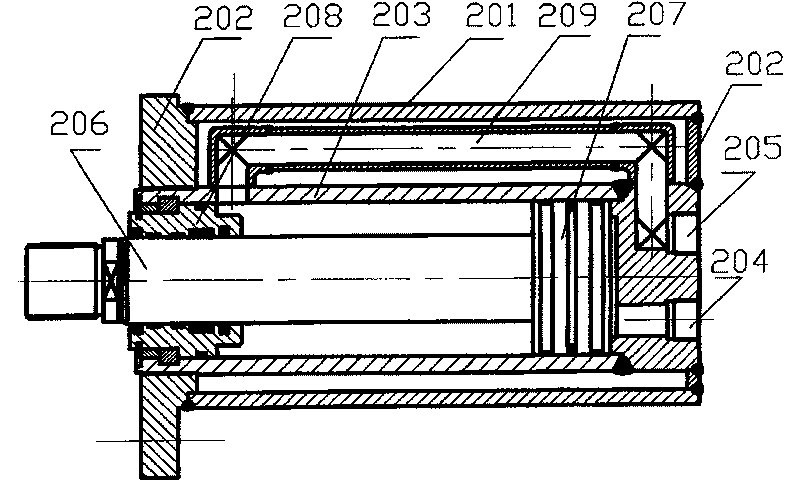

[0021] The gate valve slag retaining device includes a valve body and a valve core, and is characterized in that the valve body is composed of a connecting plate (2) part, a mounting plate (4) and a door frame (9). The inner nozzle brick (6) is fixed in the center of the connecting plate (2) ), the top of the connecting plate (2) is connected with the fixed mounting plate (4) by bolts; the central part of the mounting plate (4) is fixed with an inner slide brick (5), and the top of the mounting plate (4) is connected with the door frame (9) by a hinge pin; Door frame (9) center is fixed with outer nozzle brick (10), and door frame (9) both sides protrudes downwards and extends two rectangular slide rails, slide rail upper side is fixed with slide bar (13), on slide bar (13) A sliding frame (8) is installed in the space between the bottom and the upper surface of the mounting plate (4), the outer sliding brick (3) is installed in the center of the sliding frame (8), and the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com