Vertical heat transfer surface heat pipe radiator

A technology of heat pipe radiator and heat conduction surface, which is applied in the direction of modification through conduction heat transfer, cooling/ventilation/heating transformation, electrical components, etc., and can solve the problem of low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

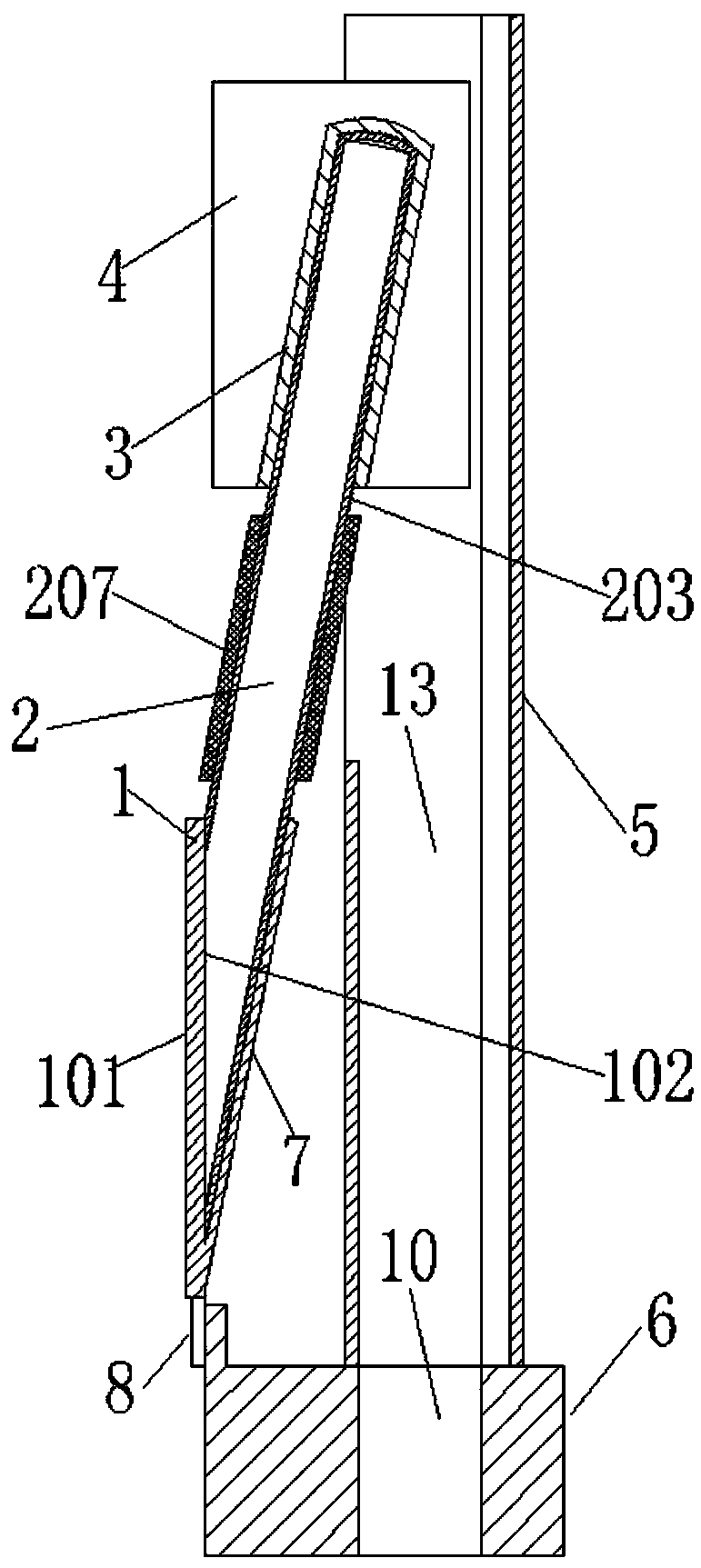

[0031] Example 1, Figure 11 is a schematic diagram of embodiment 1, wherein the radiator assembly 32 includes figure 1 The combination of all parts in the circuit board 34 is vertically installed (other components on it are omitted and not shown), the area of the heat conduction surface of the heat conduction block 1 of the evaporation section in the contact direction with the working object ≥ the area of the heat dissipation surface 33 of the heating element, And keep the whole area in close contact, and apply heat-conducting silicone grease on the contact surface; multiple identical electrical equipment mounting plates 34 are vertically parallel installed (only 2 groups are drawn in the figure, and the rest are omitted), the distance between the electrical equipment mounting plates The space is limited, because the heat of the heating element is large, and there is space in the base 36 to install the lower blower, so the method of drawing air from the top and blowing fr...

Embodiment 2

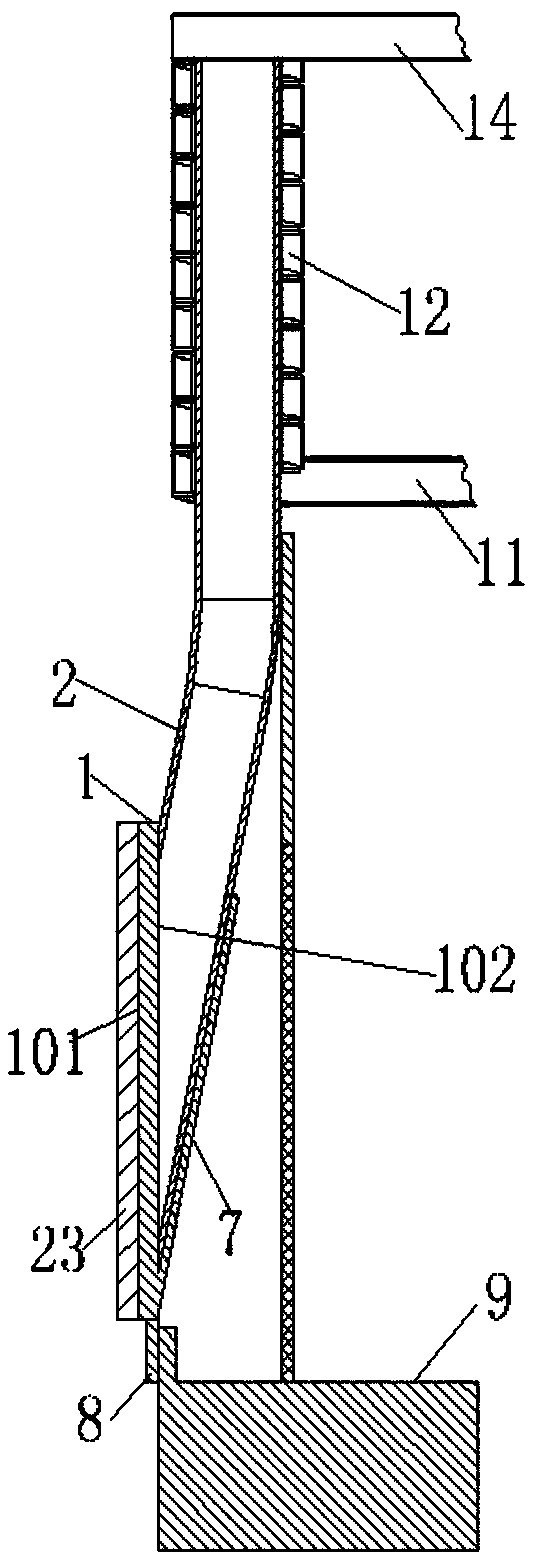

[0032] Example 2, Figure 12 is a schematic diagram of embodiment 2, Figure 13 yes Figure 12 The left view schematic diagram of ; Figure 12The electric cabinet 40 in the work is in relatively bad environment, such as outdoors, so shell 45 adopts fully enclosed structure to strengthen protection; The heat of the element is relatively large, and the heat dissipation surface is in the vertical direction, so a heat pipe radiator with a vertical heat conduction surface is adopted, and the radiator assembly 44 is composed of figure 2 The combination of all parts except the coolant tank 12, wherein the area of the heat conduction surface of the heat conduction block 43 in the evaporating section in the contact direction with the working object is ≥ the area of the heat dissipation surface 42 of the heating element, and the entire area is kept in close contact, and the contact surface is coated with Covered with heat-conducting silicone grease; the condensing section of the...

Embodiment 3

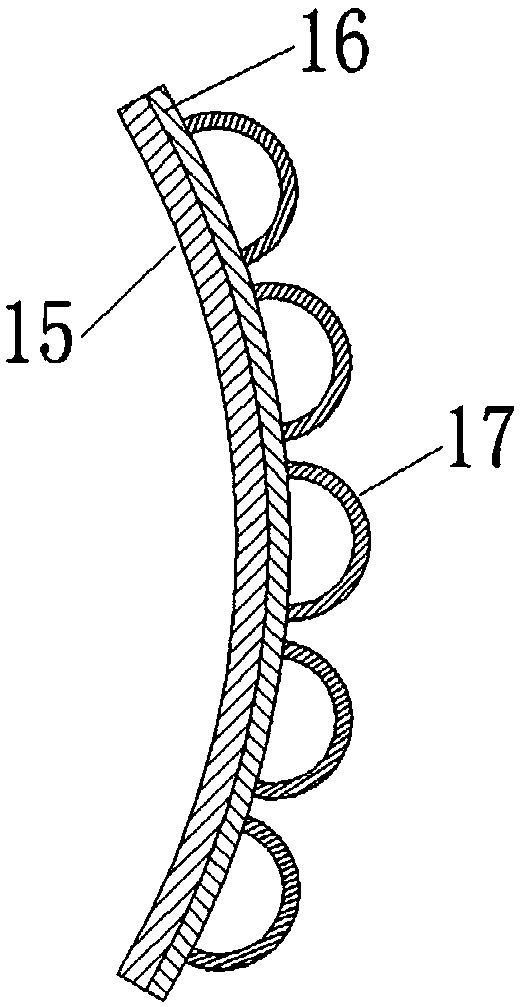

[0033] Example 3, Figure 14 is a schematic diagram of embodiment 3, Figure 15 yes Figure 13 The C-C sectional view (not a sectional view) shows the good cooperation between the section of the heat pipe assembly and the section of the heat dissipation surface of the container; the working condition is; the inside of the container 61 needs to dissipate heat, but the heat pipe radiator cannot be installed on the container cover 62, and the bottom of the container cannot Inappropriate, only the vertical sides of the container can be used to dissipate heat; the vertical heat conduction surface heat pipe radiator is adopted, and the radiator assembly 64 is included in the figure figure 1 or figure 2 The combination of all parts except the heat pipe assembly, the heat pipe assembly adopts Figure 5 As shown in the heat pipe assembly of the heat pipe radiator with the double-sided conformal vertical heat-conducting surface of the single heat pipe, the heat-dissipating surface 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com