Iron oxide cleaning device under cold bed

A cleaning device, iron oxide technology, applied in the direction of cooling bed, dust removal, cleaning method and utensils, etc., can solve the problems of low operating efficiency and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

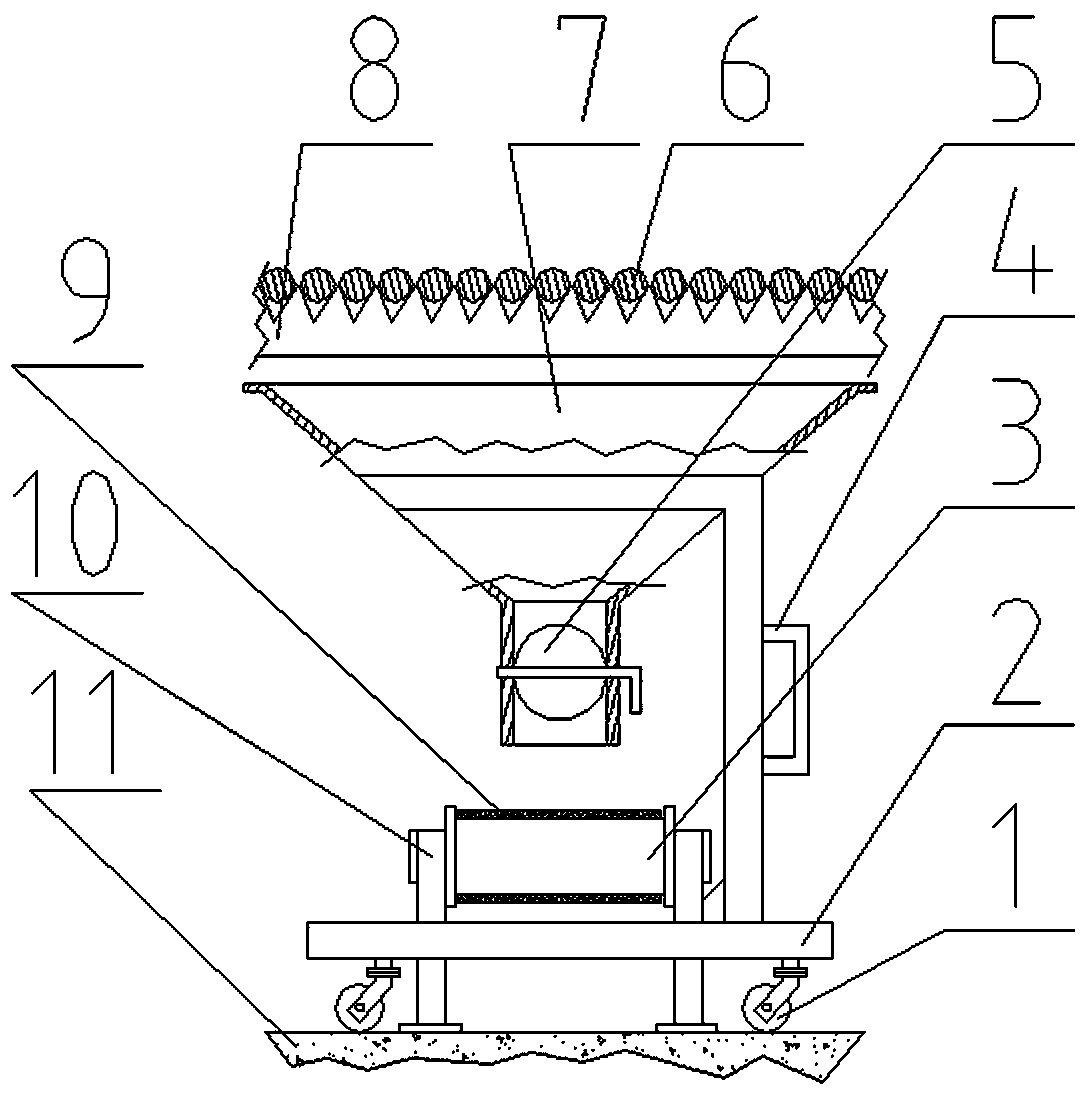

[0007] Such as figure 1 As shown, the iron oxide cleaning device under the cooling bed of the present invention mainly includes a cooling bed 8 and a rolled piece 6 . Cooling bed 8 bottoms are parked with ferric oxide collecting car, and the iron oxide collecting car top has the funnel compartment 7 of bucket-shaped structure, discharge valve 5, and the frame 2 of C-shaped structure, handle 4, universal wheel 1 are equipped with in the bottom. Belt conveyor is also equipped with in cooling bed 8 bottoms, and it comprises roller 3, conveyer belt 9. The frame 2 of the C-shaped structure of the iron oxide collection vehicle can be inserted below the conveyor belt 9 . The iron oxide scale inside it can just fall on the top of the conveyor belt 9 when the discharge valve 5 is opened.

[0008] Such as figure 1 As shown, the iron oxide scale produced by the rolled piece 6 on the top of the cooling bed 8 during transportation falls off in the funnel cabin 7 downwards, and when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com