A concrete production equipment system

A technology for production equipment and concrete, which is applied to clay preparation devices, mixed operation control, mixed operation control devices, etc., can solve the problems of reducing work efficiency, time-consuming and laborious, etc., and achieve the effects of improving work efficiency, reducing waste and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

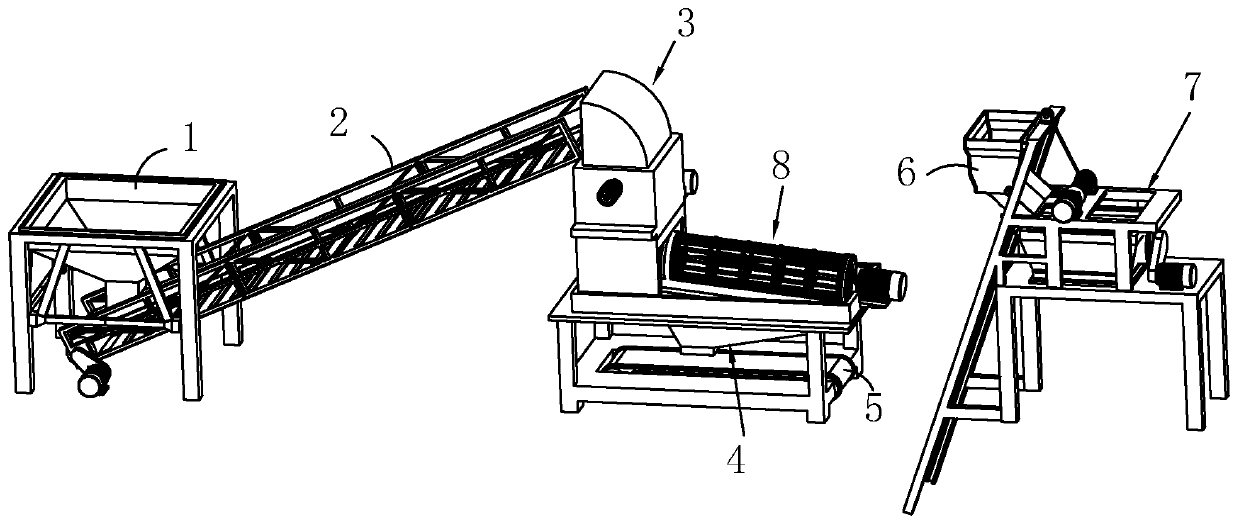

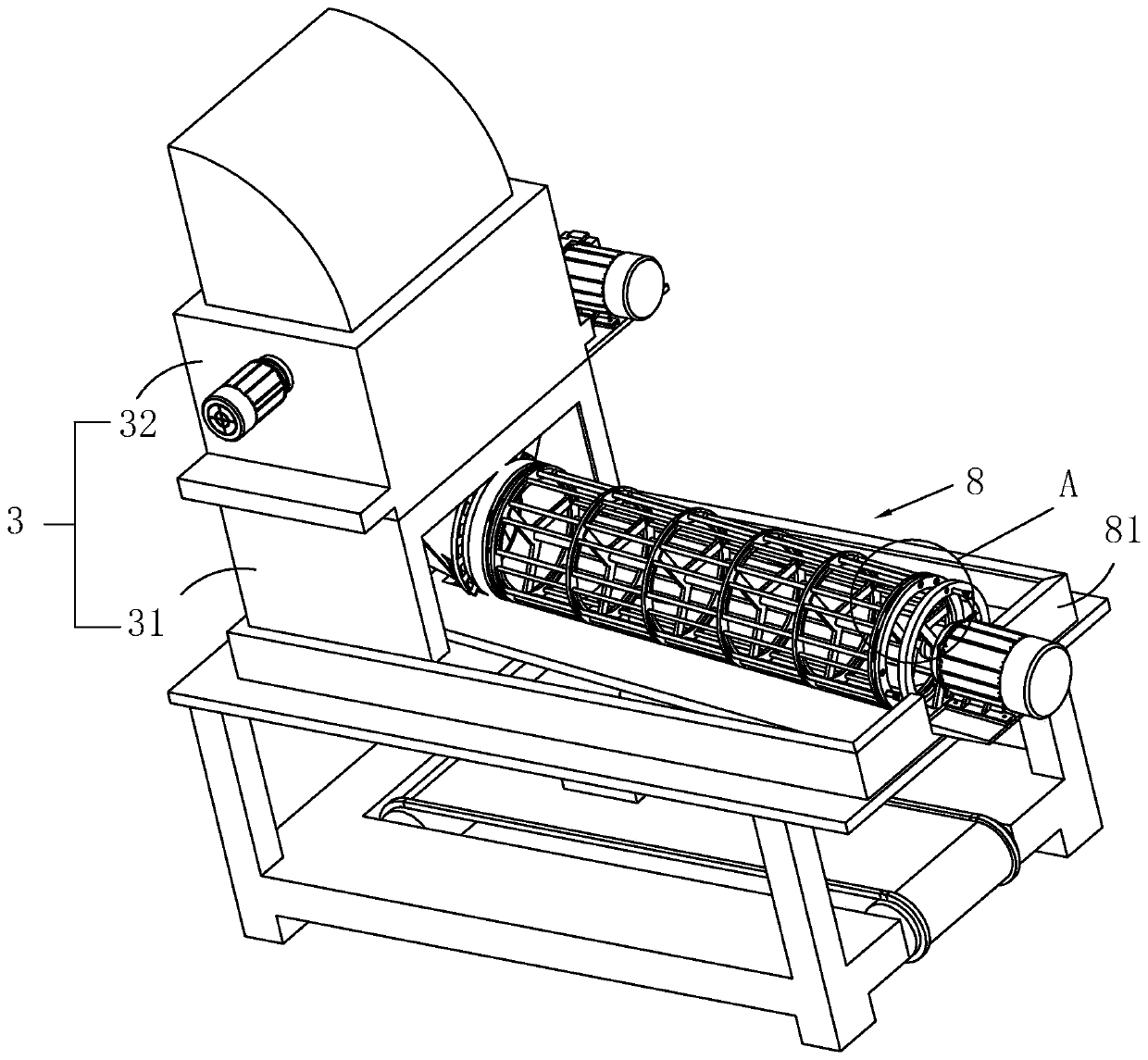

[0041] Such as figure 1 , 2 As shown, a concrete production equipment system includes a sand and gravel silo 1, an inclined belt conveyor 2, a feeding device 3, a weighing bucket 4, a flat belt conveyor 5, a lifting hopper 6 and a mixer 7 arranged in sequence, and the feeding The device 3 includes a bracket 31 and a feeding hopper 32 fixedly arranged on the bracket 31 , and a sand screening machine 8 is also arranged between the feeding hopper 32 and the weighing hopper 4 .

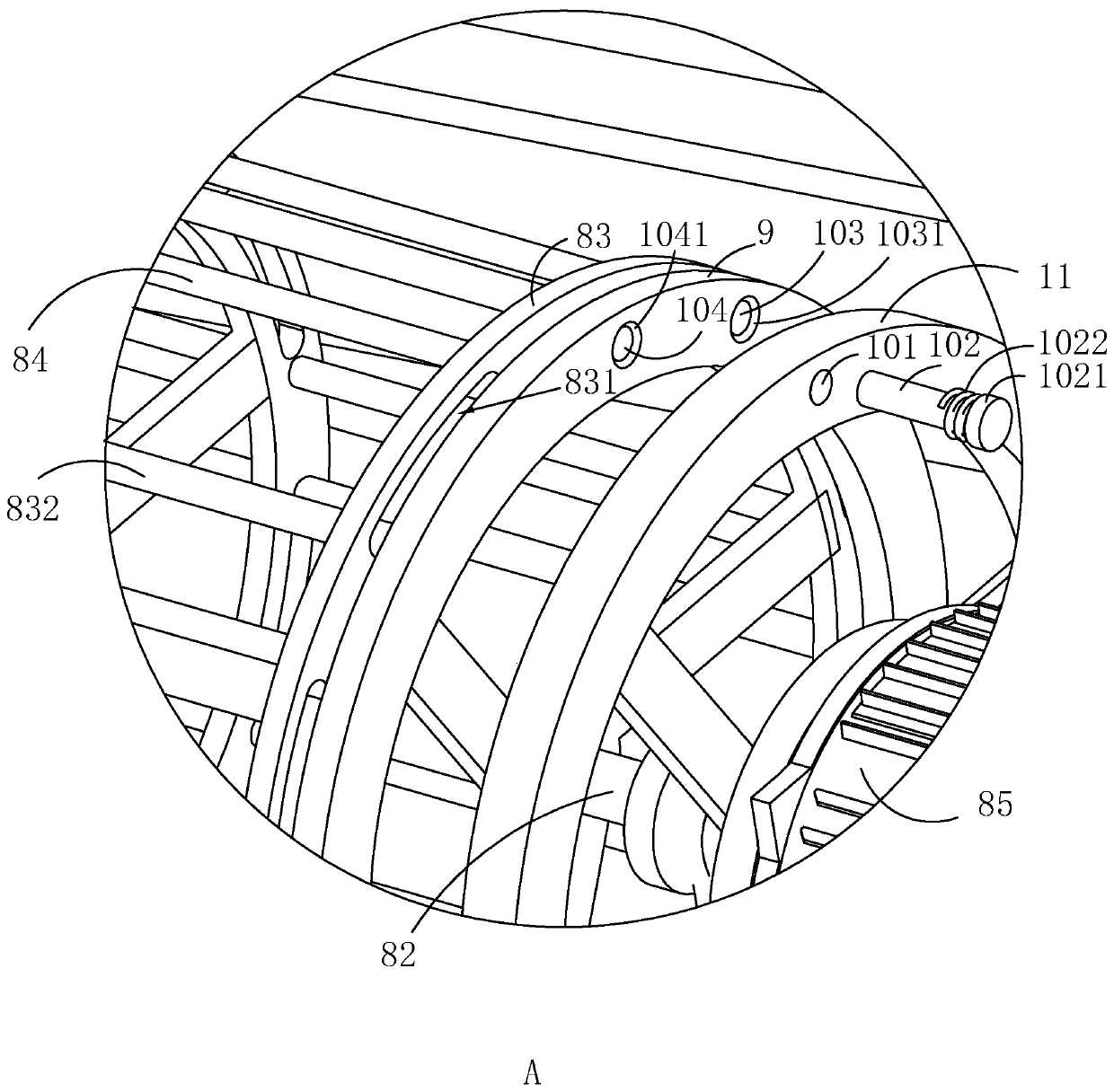

[0042] Such as figure 2 , 3 As shown, the sand screening machine 8 includes a frame 81, a rotating shaft 82 arranged on the frame 81 is rotated, and installation rings 83 fixedly arranged at both ends of the rotating shaft 82 are arranged in an array along the circumference of the installation ring 83 and are fixedly connected between the two installation rings 83. A plurality of fixed rods 84 are fixed on the frame 81 and are used to drive the motor 85 of the rotating shaft 82 to rotate, and the dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com