Convenient-to-overhaul tail water cooler device

A cooler and tail water technology, which is applied in hydropower, water conservancy projects, hydropower stations, etc., can solve the problems of difficult, dangerous, and inconvenient underwater operations, and achieve improved maintenance efficiency, convenient maintenance, and The effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

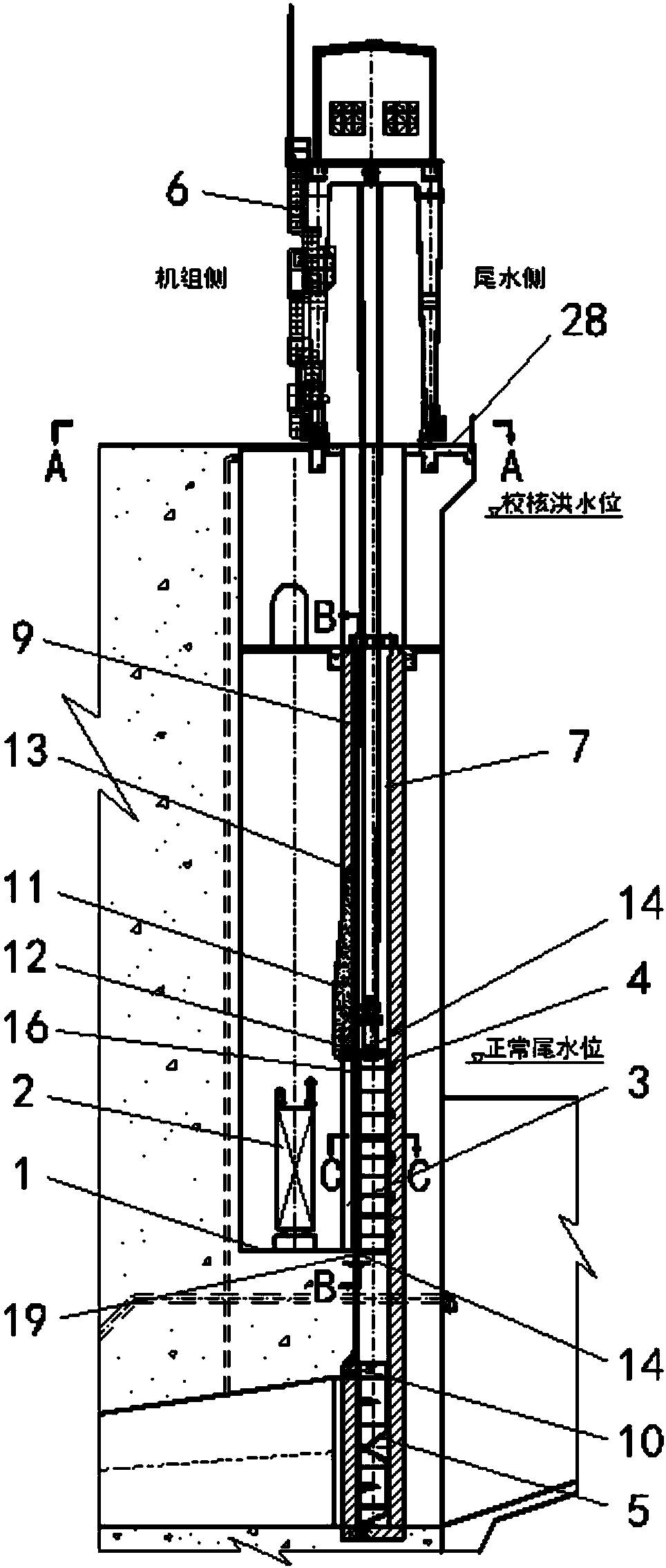

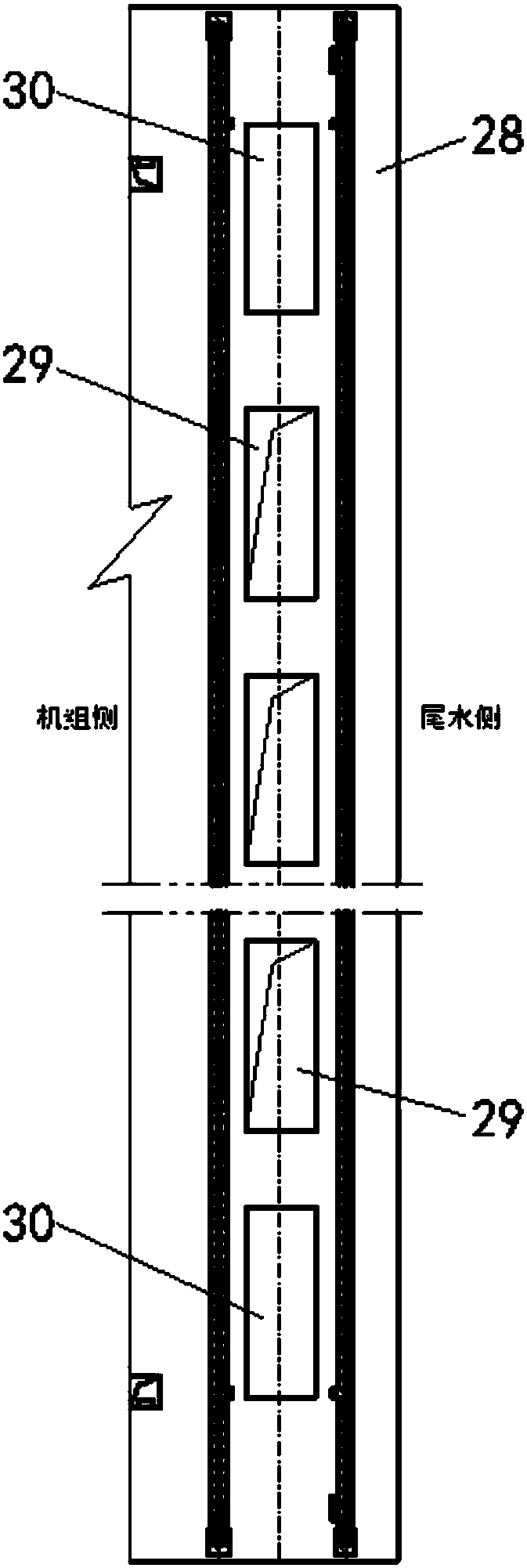

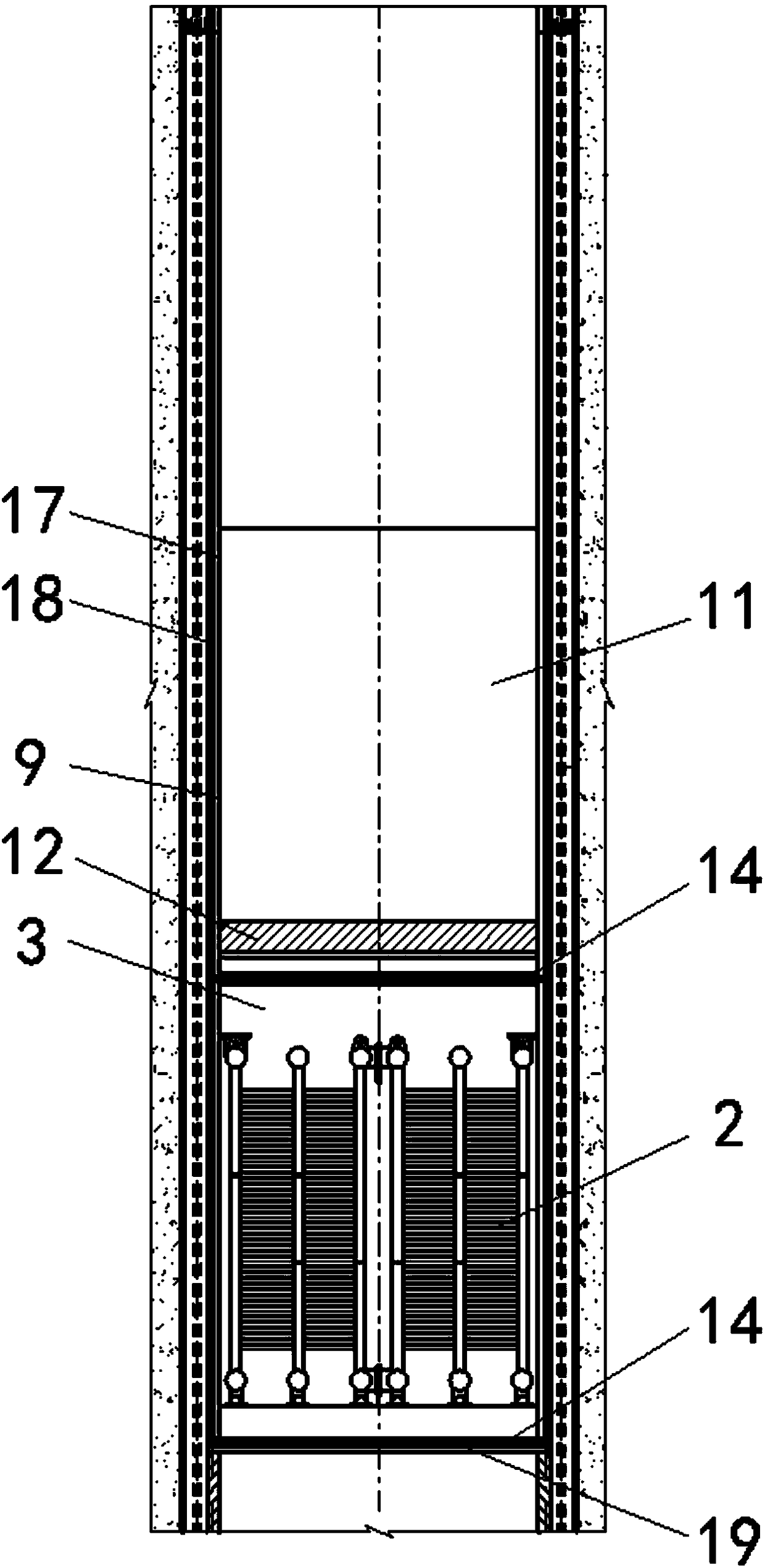

[0026] In this example, the device for easy inspection and maintenance of the tail water cooler is to install a rectangular submerged hole 3 on the upper platform 1 that meets the requirements of the flowing cooling water body for the heat exchange of the tail water cooler 2, and set a submerged hole on the tail water side of the rectangular submerged hole 3 The gate 4, the submersible gate 4 and the tailgate 5 share a door slot 7; and share the gate machine 6 of the tailgate 5 for operation. H-shaped water seal support assemblies 9 are respectively arranged in the rectangular gaps 8 of the gate grooves 7 at both ends of the tail water maintenance gate 5 . The width of the rectangular notch 8 is equal to the distance between the outer edge of the tail water side of the upper platform 1 and the outer edge of the tail water side of the lintel 10 of the tail water gate, which is 50-200 mm; For normal tail water level height, submersible gate lintel 12 is installed at the lower pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com