Metal high-efficiency energy consumption damper

A damper, high-efficiency technology, applied in the direction of building components, building types, shock-proof, etc., to reduce adverse effects and improve shock-absorbing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

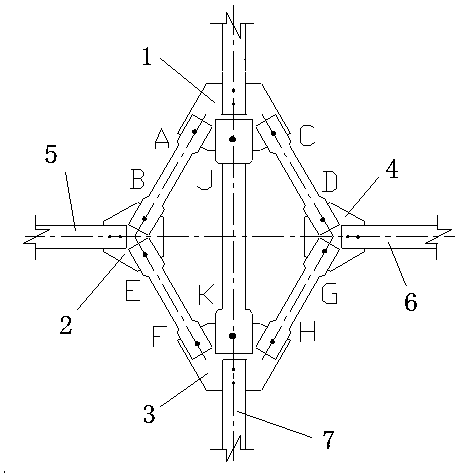

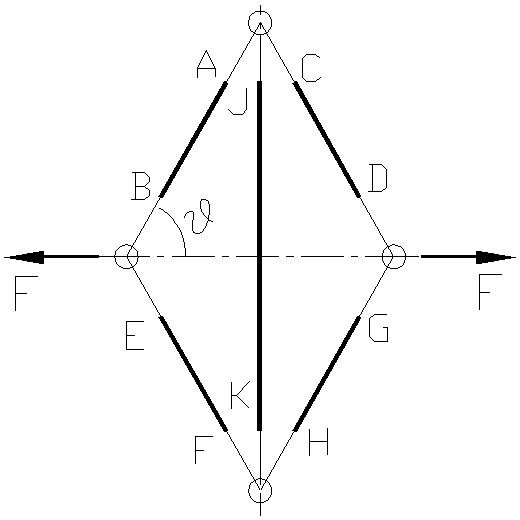

[0016] A metal high-efficiency energy-dissipating damper, which is composed of the 1st-5th energy-dissipating members (AB, EF, GH, CD, JK) and the 1st-4th node plates, all of which are made of mild steel. The upper end of the bar AB and the upper end of the fourth energy-dissipating bar CD are fixed on the first gusset plate 1 by bolts, and the lower end of the second energy-dissipating bar EF and the lower end of the third energy-dissipating bar GH are both fixed by bolts On the third gusset plate 3, the lower end of the first energy dissipation member AB and the upper end of the second energy dissipation member EF are fixed on the second gusset plate 2 by bolts, and the lower end of the fourth energy dissipation member CD and the second 3 The upper ends of the energy-dissipating members GH are all fixed on the fourth gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com