A high heat dissipation garden lamp structure

A technology of garden lights and high heat dissipation, which is applied in gardening, lighting and heating equipment, and components of lighting devices, etc. It can solve the problems of unsatisfactory heat dissipation performance of garden lights, increase the cost of garden maintenance facilities, and fail to meet the needs of garden use. Achieve the effects of improving water flow utilization, lowering temperature, and multiple functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0018] Example.

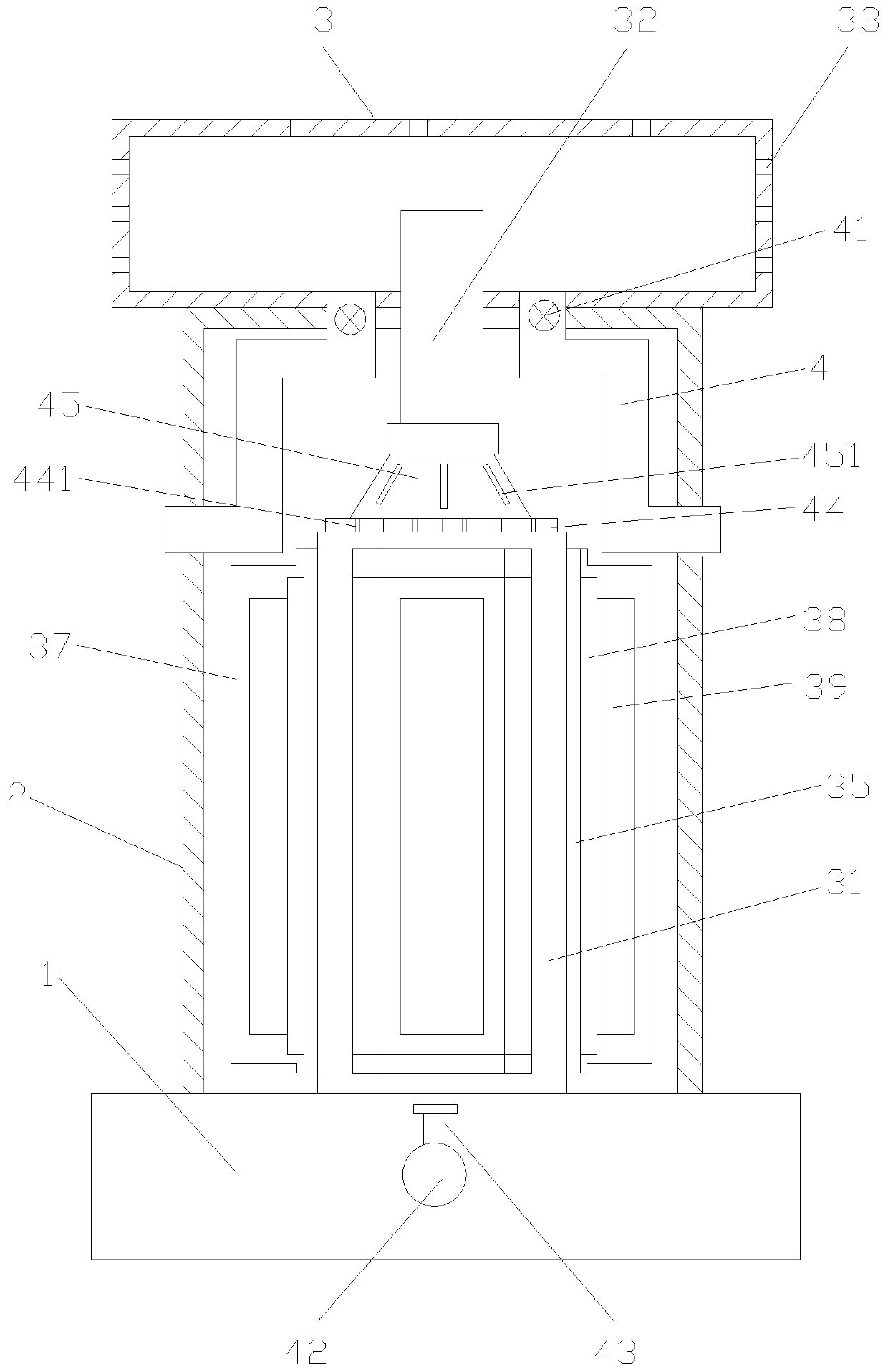

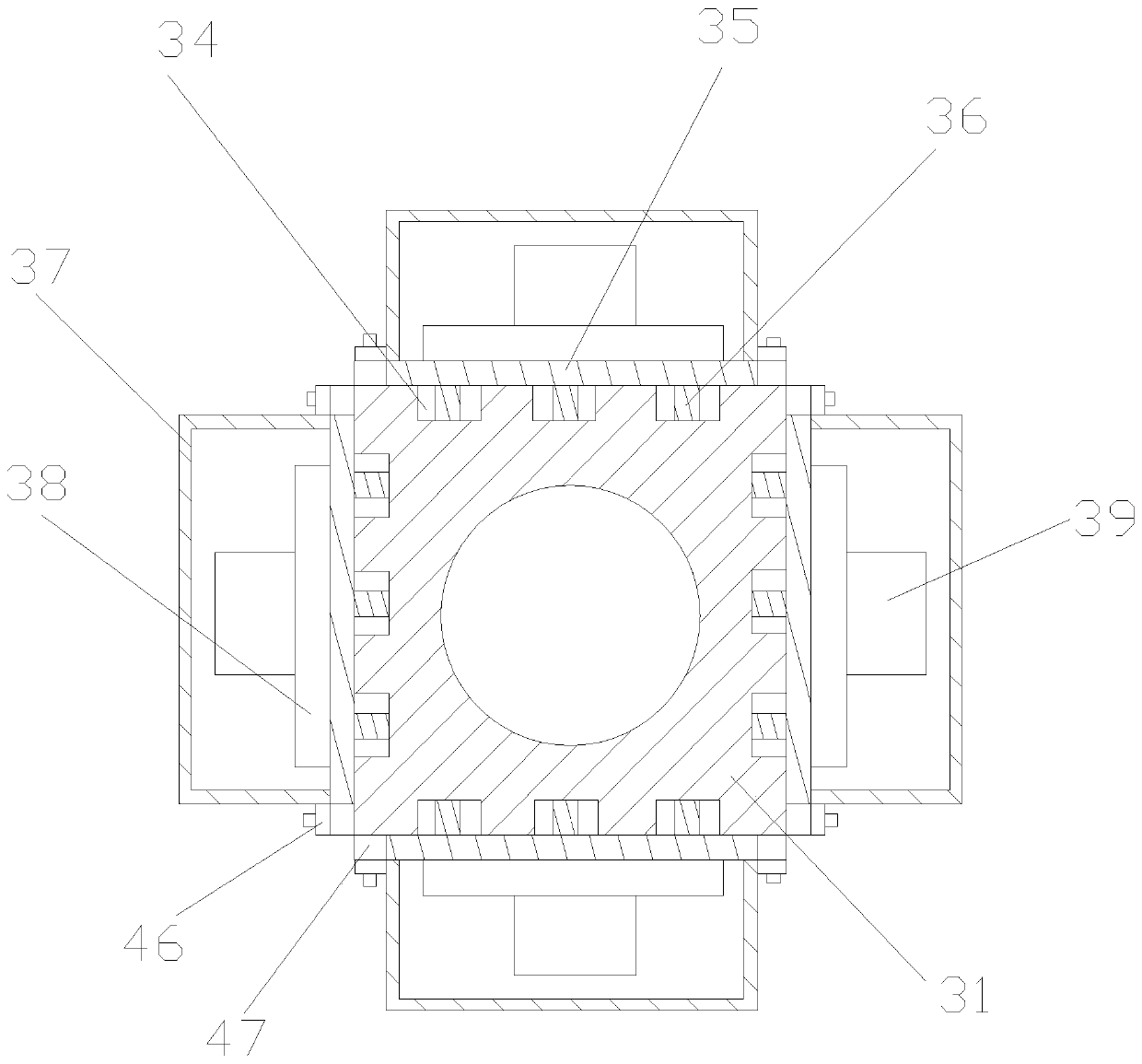

[0019] Such as figure 1 , figure 2 As shown, a high heat dissipation garden lamp structure includes a lamp holder 1, a lamp post 2 is provided above the lamp holder 1, a sprinkler 3 is provided above the lamp post 2, and the lamp post 2 Inside is provided with a water tank 31, the upper end of the water tank 31 is provided with a water spray pipe 32, one end of the water spray pipe 32 communicates with the water tank 31, and the other end of the water spray pipe 32 extends upwards into the water sprayer 3, the water spray The top surface and the side of device 3 are all provided with some spray holes 33; All sides of described water tank 31 are provided with heat conduction plate 35, and the side wall of described water tank 31 is provided with some grooves 34, and described hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com