Blade shearing type corn ear picking mechanism

A corn ear and shearing technology, which is applied in the field of corn ear picking operation mechanism, can solve the problems of slippage between the stem roller and the corn stalk, excessive length of corn ear stalk, and increased harvest loss, and achieve the quality of the harvested ear Good, less power consumption for ear picking, and shorter ear stalk length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

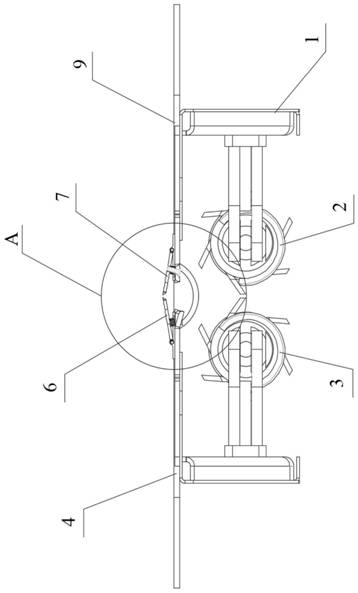

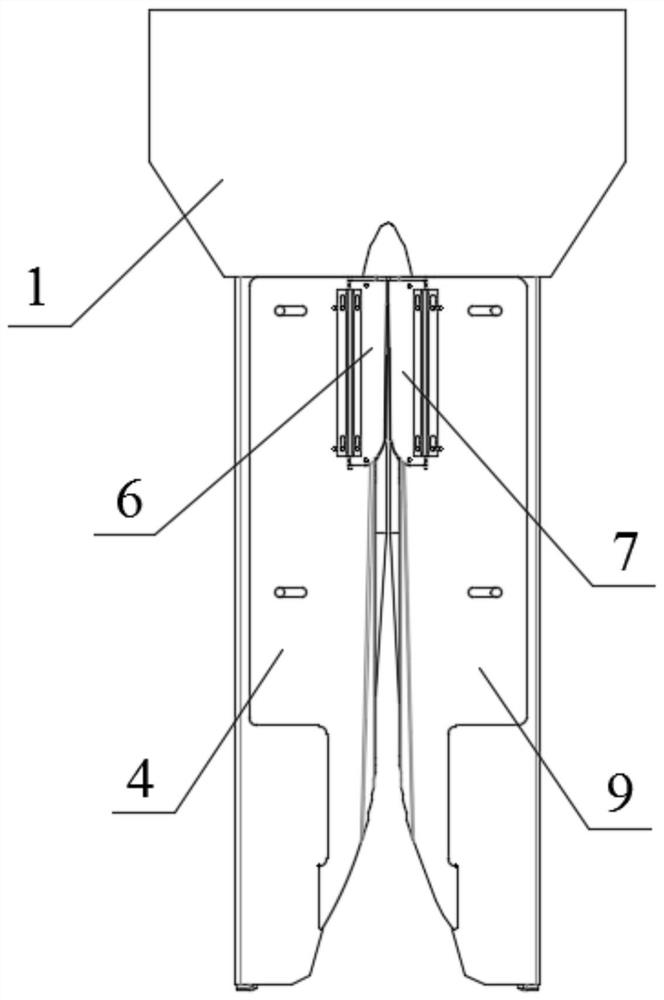

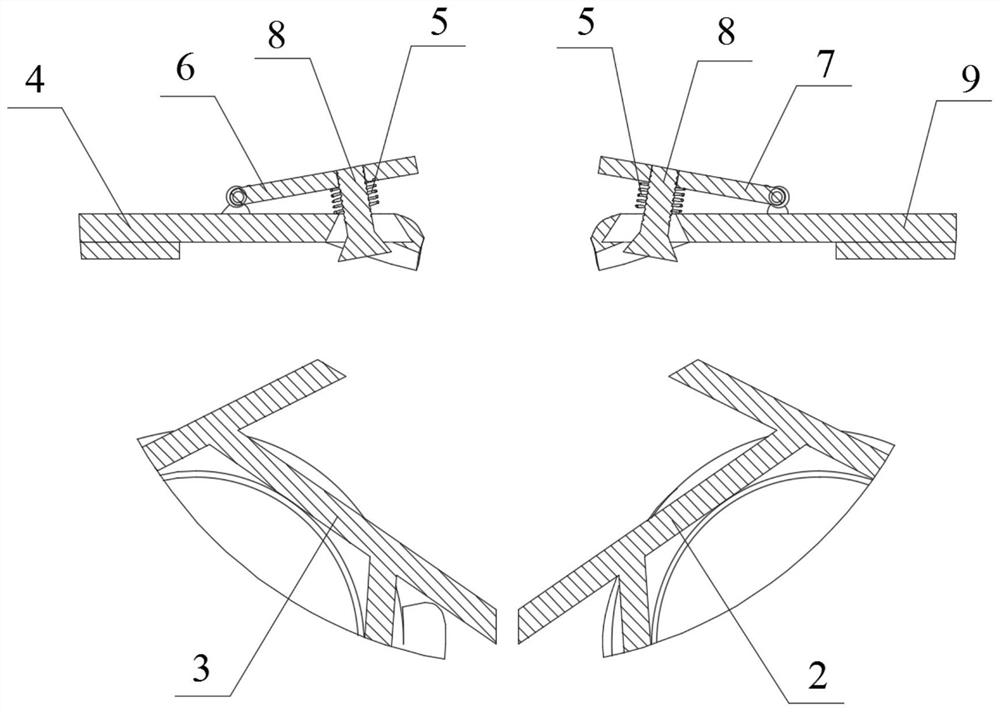

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A blade shearing type corn ear picking mechanism includes a frame body 1, a left stem roller 3, and a right stem roller 2, and the left stem roller 3 and the right stem roller 2 are symmetrically installed on the inside of the frame body 1 On the bottom, on the upper side of the frame body 1, at the position above the left stem roller 3 and the right stem roller 2, the left seat plate 4 and the right seat plate 9 are equipped respectively, and the left seat plate 4 and the right seat plate The left shear blade 6 and the right shear blade 7 are hingedly installed on the relative inner part of the right seat plate 9, which can swing up and down respectively. Cutting fit, on the left seat plate 4 and the right seat plate 9, the axially movable spacer pins 8 are installed respectively, and the spacer pins 8 on the left seat plate 4 are connected with the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com