Bush fruit harvester

A technology for harvesters and shrubs, which is applied to harvesters, picking machines, agricultural machinery and implements, etc., can solve problems such as increased costs, limited range of activities, and easy injury of pome fruits and berries, so as to improve efficiency, avoid fruit damage or damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

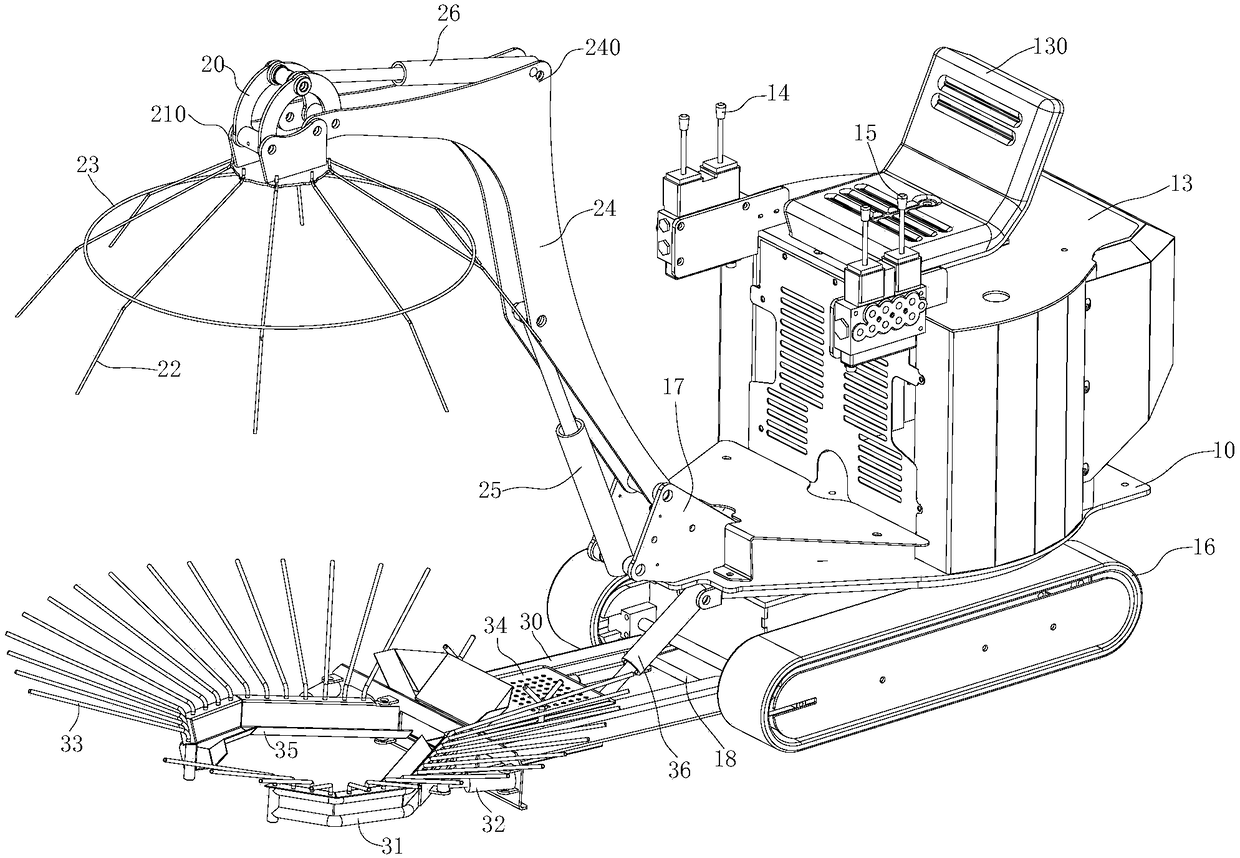

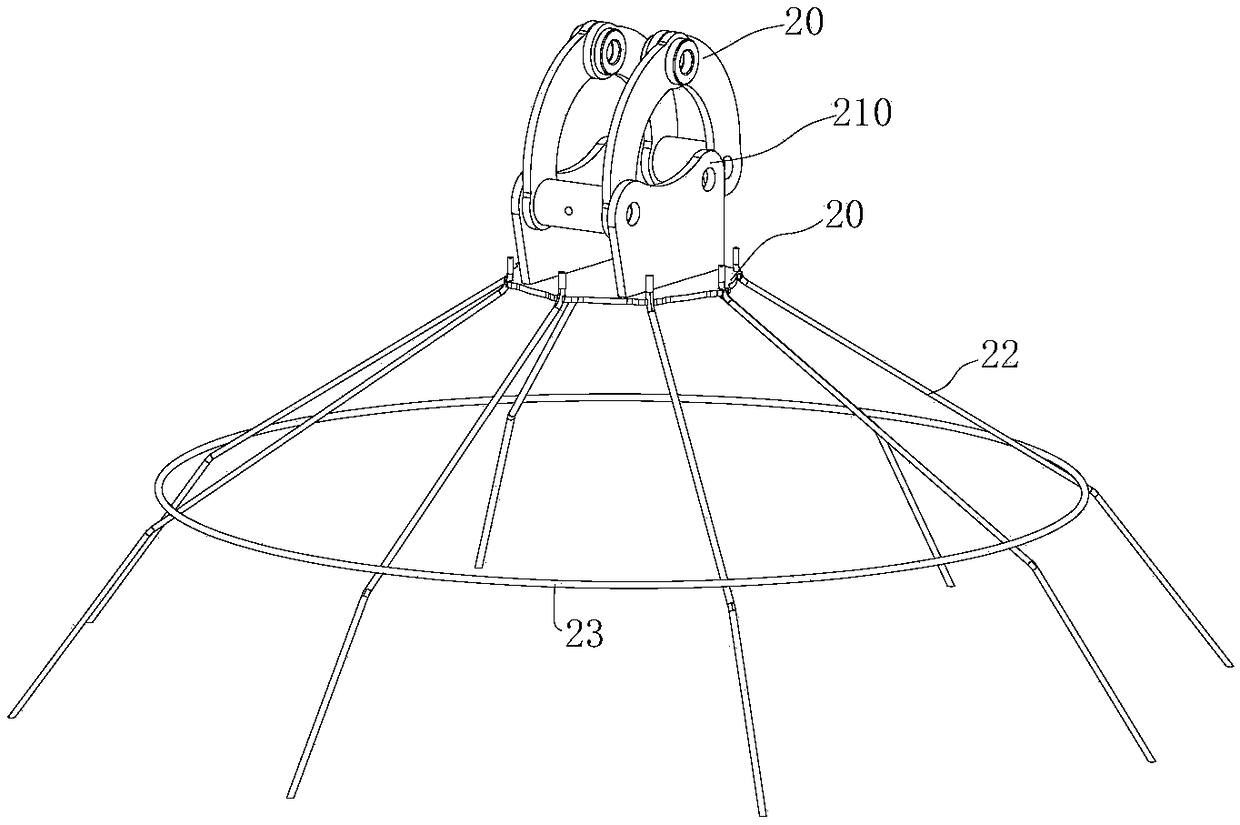

[0027] like figure 1 As shown, the shrub fruit harvester of the present invention includes a walking device, a tree cover mechanism that shakes or pats the shrub, and a part is used to surround the shrub tree pole and fall when the tree cover mechanism shakes or pats the shrub. The fruit collection organization that collects the fruits. The following describes each part and the relationship between them in detail:

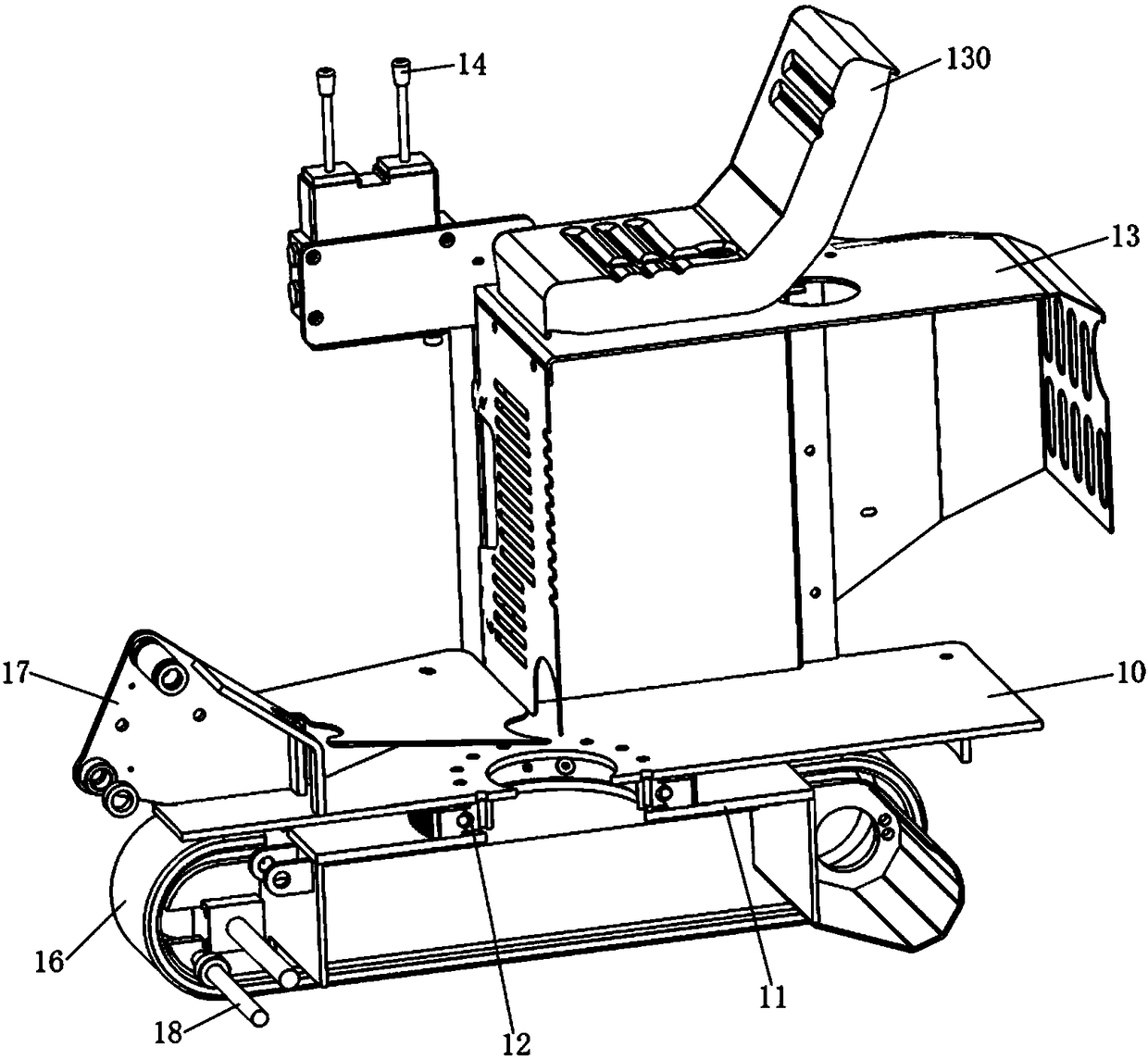

[0028] like figure 1 and figure 2 As shown, the walking device includes an upper seat 10, a lower seat 11 and a rotary drive mechanism 12, the upper seat 10 is connected with one end of the rotary drive mechanism, the lower seat 11 is connected with the other end of the rotary drive mechanism 12, and one end of the tree cover mechanism Connect with the upper seat 10 of the running gear.

[0029] like figure 1 and figure 2 As shown, the preferred structure of the slewing drive mechanism 12 includes a slewing bearing, a driving gear (not shown in the figure) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com