Foam generating module and foam fire-fighting equipment

A foam and generator technology, applied in the field of foam generating modules and foam fire extinguishing equipment, to achieve the effect of small size and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

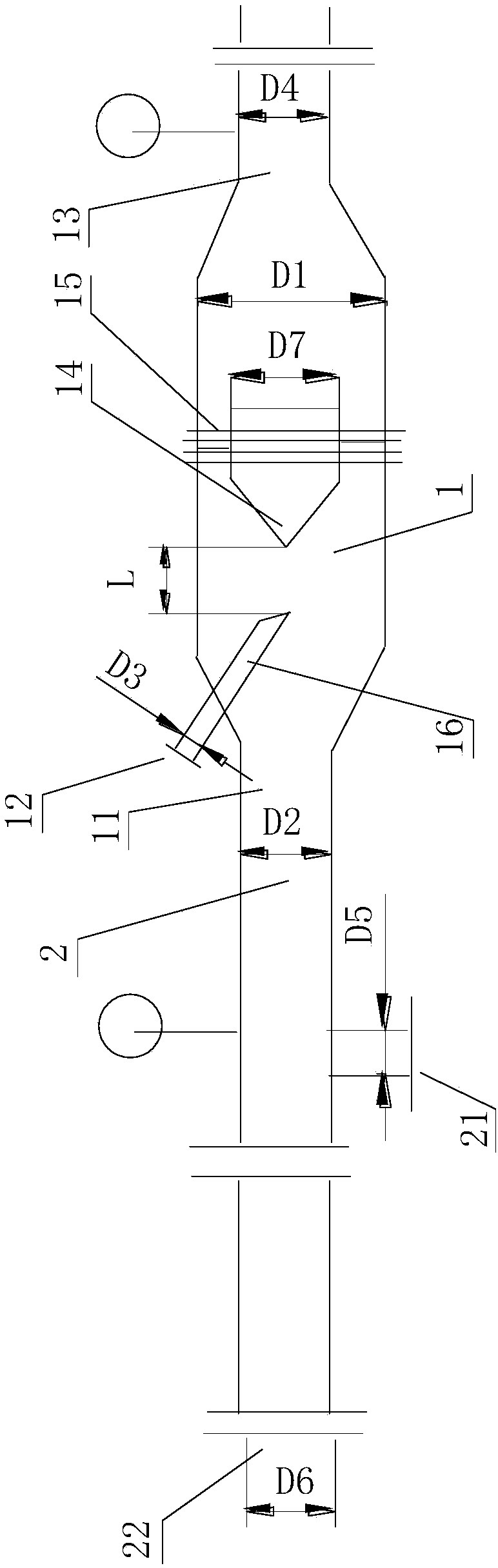

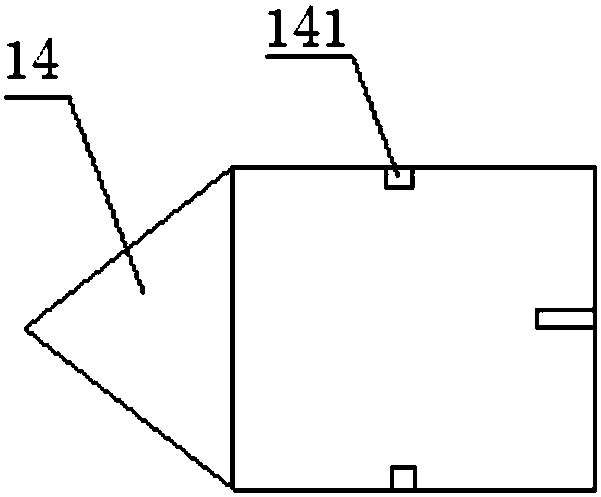

[0075] For the foam generation module in the CAFS in this embodiment, the foam outlet and the foam mixture inlet of the foam generator 1 are respectively located at both ends of the cylindrical structure. The relationship between the diameter D2 of the foam mixture inlet and the diameter D3 of the liquid nitrogen inlet is: D2 / D3=8; the relationship between the diameter D1 of the cylindrical structure and the diameter D2 of the foam mixture inlet is: D1 / D2= 1.4; the relationship between the diameter D1 of the cylindrical structure and the diameter D4 of the foam outlet is: D1 / D4=1.2; the angle between the direction of the liquid nitrogen inlet and the direction of the foam mixture inlet is 30°. A spoiler is arranged in the foam generating chamber, and the spoiler is formed as image 3 As shown in the conical structure, the conical apex of the conical structure faces the inlet of the foam mixture, the cross section of the spoiler is a circular structure, and the diameter D7 of t...

Embodiment 2

[0090] The CAFS in this embodiment is basically the same as the CAFS in the above-mentioned embodiment one, and the difference is that the relationship between the diameter D2 of the foam mixture inlet of the foam generator in this embodiment and the diameter D3 of the liquid nitrogen inlet is: D2 / D3=10; the relationship between the diameter D1 of the cylindrical structure and the diameter D2 of the foam mixture inlet is: D1 / D2=1.7. The test results of using the CAFS to extinguish the fire show that the fire extinguishing time is 22 minutes, the actual foaming ratio is 7, and the foam performance is stable.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap