Integrated heat radiating device of super-gravity acceleration high-speed geotechnical centrifuge

A technology of geotechnical centrifuge and high-speed centrifuge, which is applied in the direction of centrifuge, soil material test, material inspection product, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

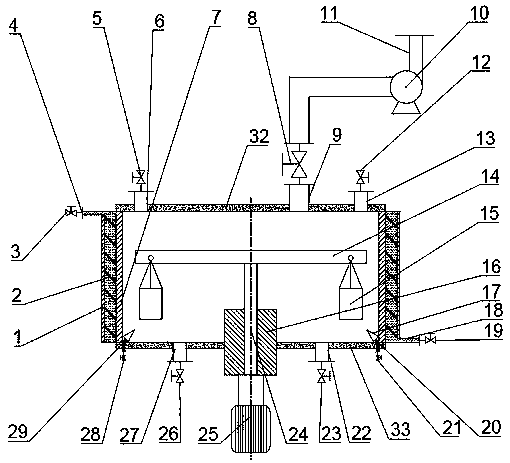

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

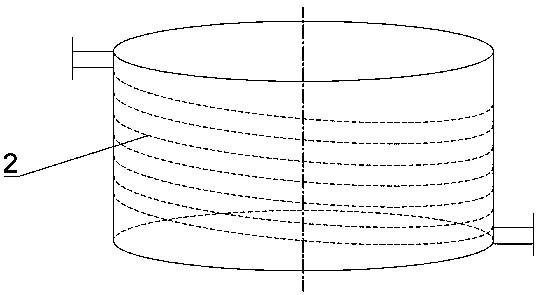

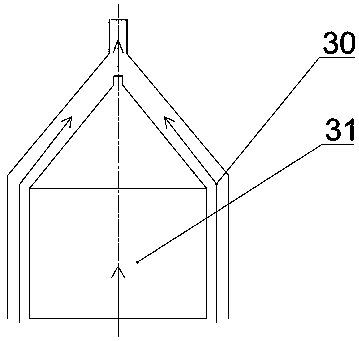

[0026] like figure 1 As shown, the high-speed centrifuge rotor of the present invention is wrapped in a cylindrical centrifugal bulkhead 7, the outer side of the centrifugal bulkhead 7 is a cylindrical cold water jacket 1, and the cylindrical centrifugal bulkhead 7 and the cylindrical cold water jacket 1 is installed with a spiral deflector 2, and the composite upper cover 32 and the composite lower cover 33 of the cylindrical centrifugal bulkhead 7 are airtightly connected with the centrifugal bulkhead; the composite upper cover 32 is provided with the first cold air outlet pipe 6, the second Two cold air outlet pipes 13 and vacuum suction pipes 9; the center of the composite lower cover 33 is provided with centrifuge support 16 mounting holes, and the composite lower cover 33 is provided with a first cold air inlet pipe 27, a second cold air inlet pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com