Backmixing preventing system

An anti-return and ash hopper technology, which is applied in the direction of the swirl axis can be reversed, the swirl device, etc., to achieve the effect of improving the discharge quality and reducing the escape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

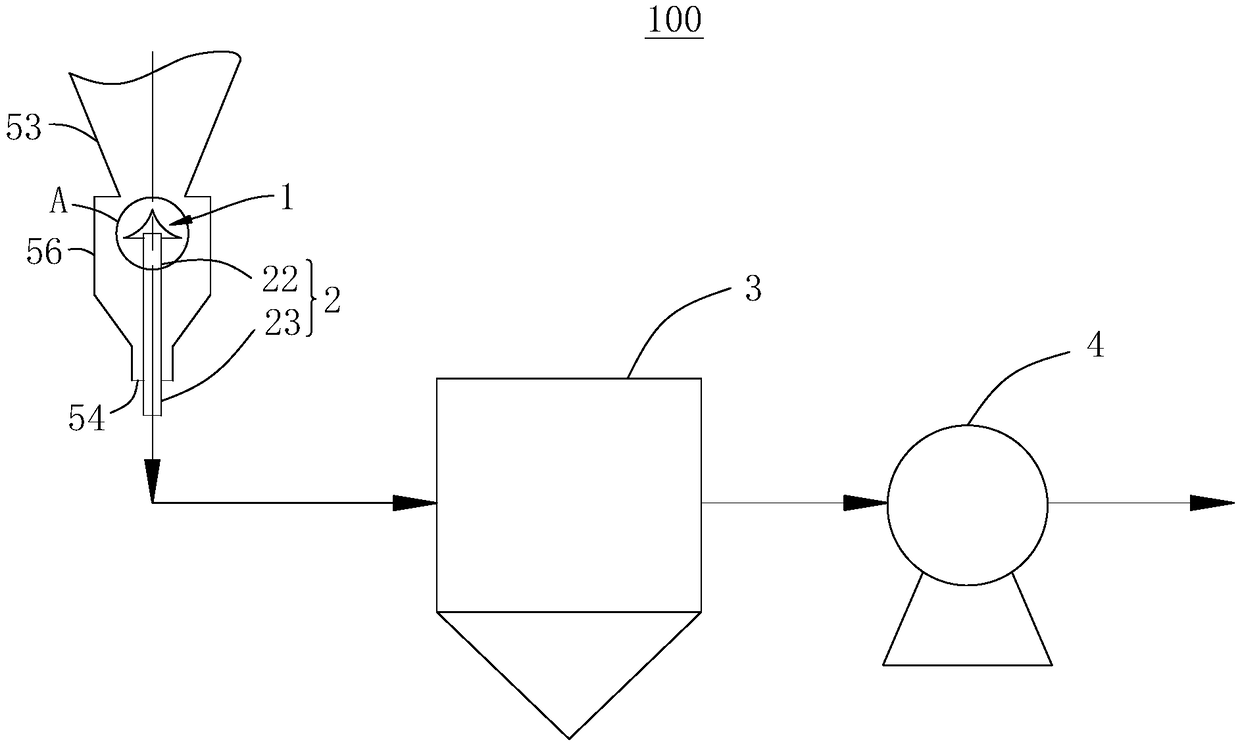

[0032] Please refer to figure 2 This embodiment provides an anti-backmixing system 100, which is applied in the ash hopper 56 of a cyclone dust collector, and includes an anti-backmixing cone 1 and an air extraction mechanism.

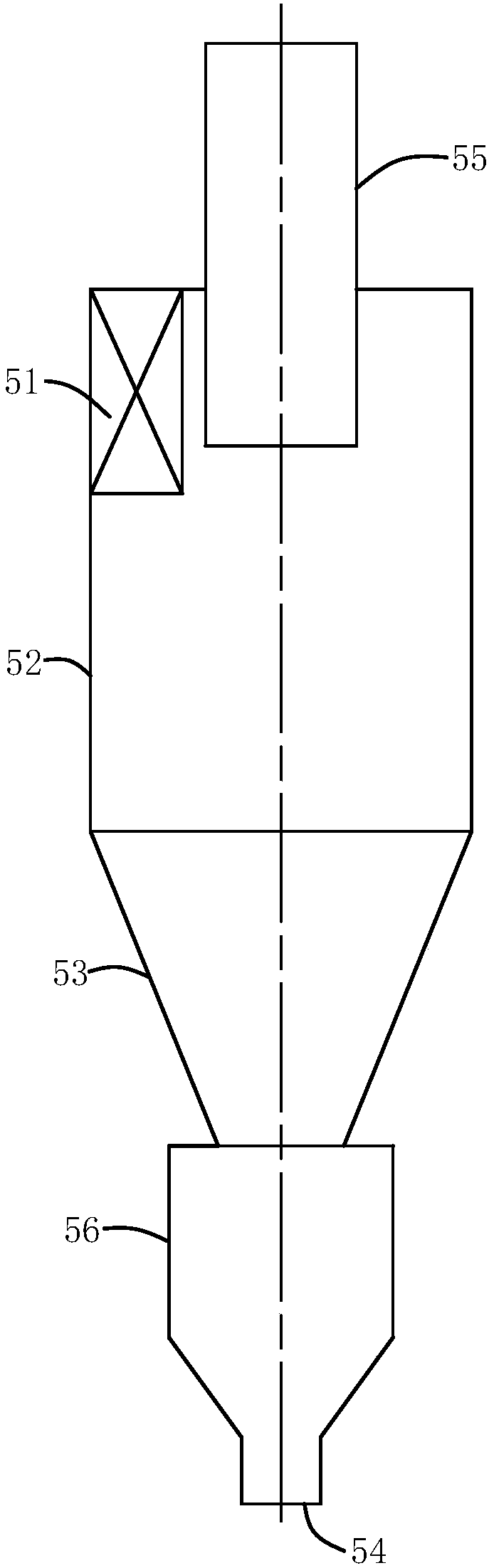

[0033] Such as figure 1 As shown, according to the structure of the cyclone dust collector, the dust collector separation section includes a separation cylinder section 52 and a separation cone section 53, the separation cylinder section 52 is connected to the separation cone section 53, and the dust-containing gas inlet 51 of the cyclone dust collector is located in the separation cylinder In section 52, the bottom of the separating cone section 53 is connected to the ash hopper 56. The separated high-concentration dust-containing gas enters the ash hopper 56 through the inlet of the ash hopper 56; the purified gas is discharged from the gas riser 55. In this embodiment, the anti-backmixing system 100 is adopted on the existing cyclone dust collector, th...

no. 2 example

[0050] Researchers have studied the anti-backmixing system 100 provided by the present invention, based on the above-mentioned first embodiment, can also make the following optional other structural solutions, which are specifically described as follows:

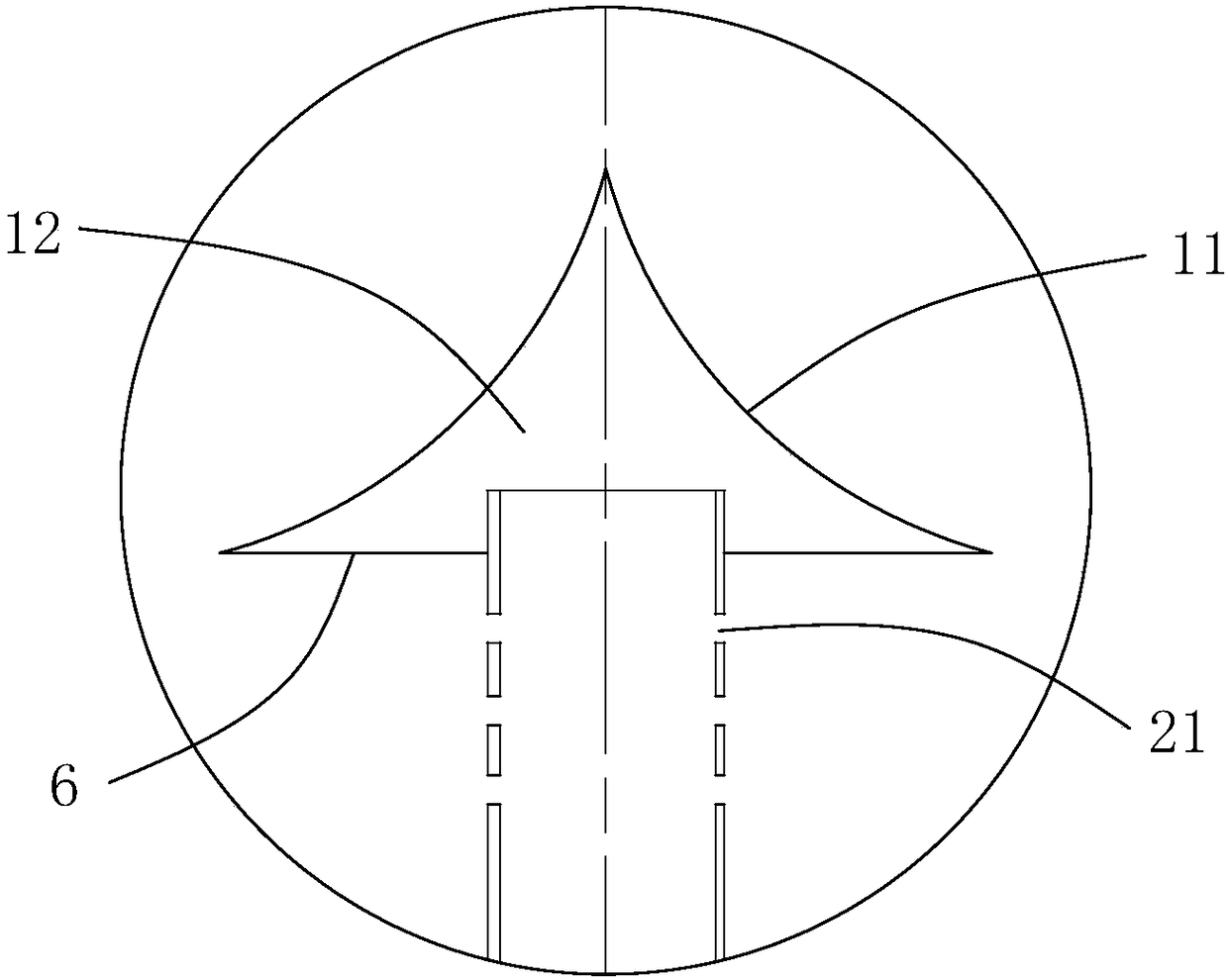

[0051] Such as Figure 5 As shown, in this embodiment, the fixing assembly 6 includes a disc 62, the disc 62 is connected to the bottom of the concave circular arc conical surface 11, the disc 62 closes the open end of the containing cavity 12, and the suction pipe 2 passes through the disc 62 Extending into the accommodating cavity 12, the disc 62 is provided with a plurality of vent holes 63, the vent holes 63 are arranged around the circumference of the disc 62, the vent holes 63 penetrate the disc 62, so that the cavity in the ash hopper 56 and the accommodating cavity 12 is connected, and the dust-containing gas enters the containing cavity 12 through the vent 63 under the action of the suction assembly 4, and then enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com