Oil-spraying rust preventing device for mechanical component

A technology for mechanical parts and oil suction pipes, which is applied in the field of anti-rust devices for machinery, can solve the problems of low efficiency of oiling and anti-rust, time-consuming and labor-intensive, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

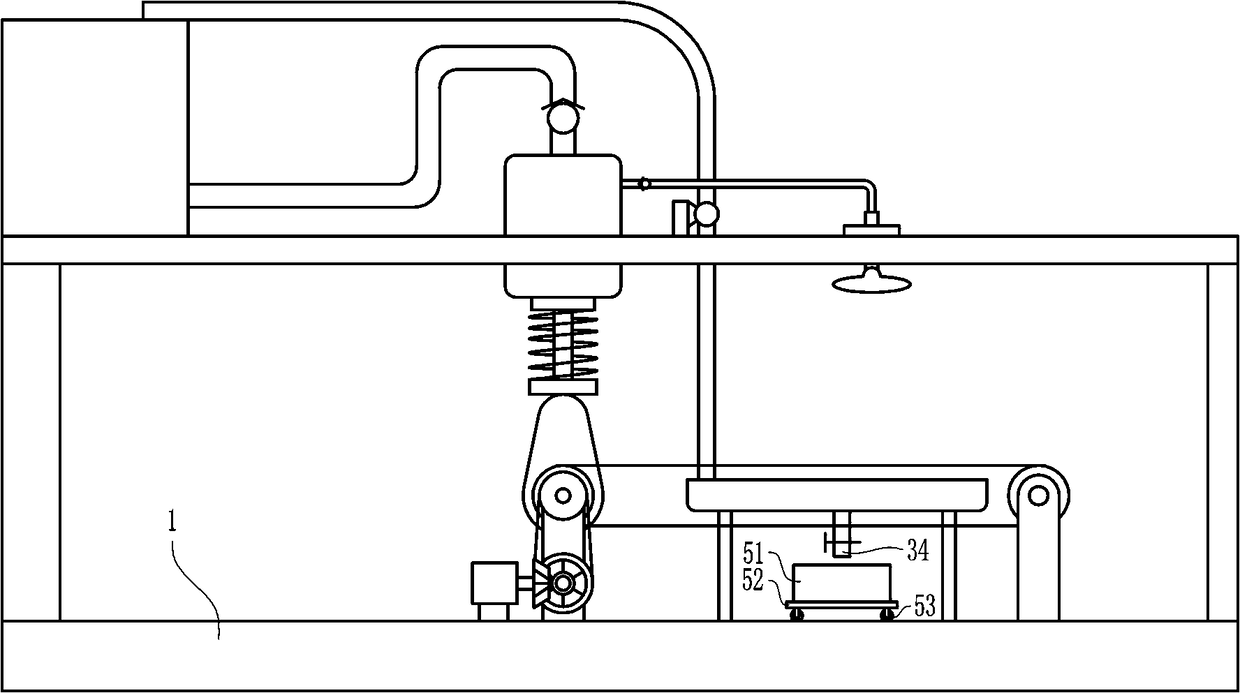

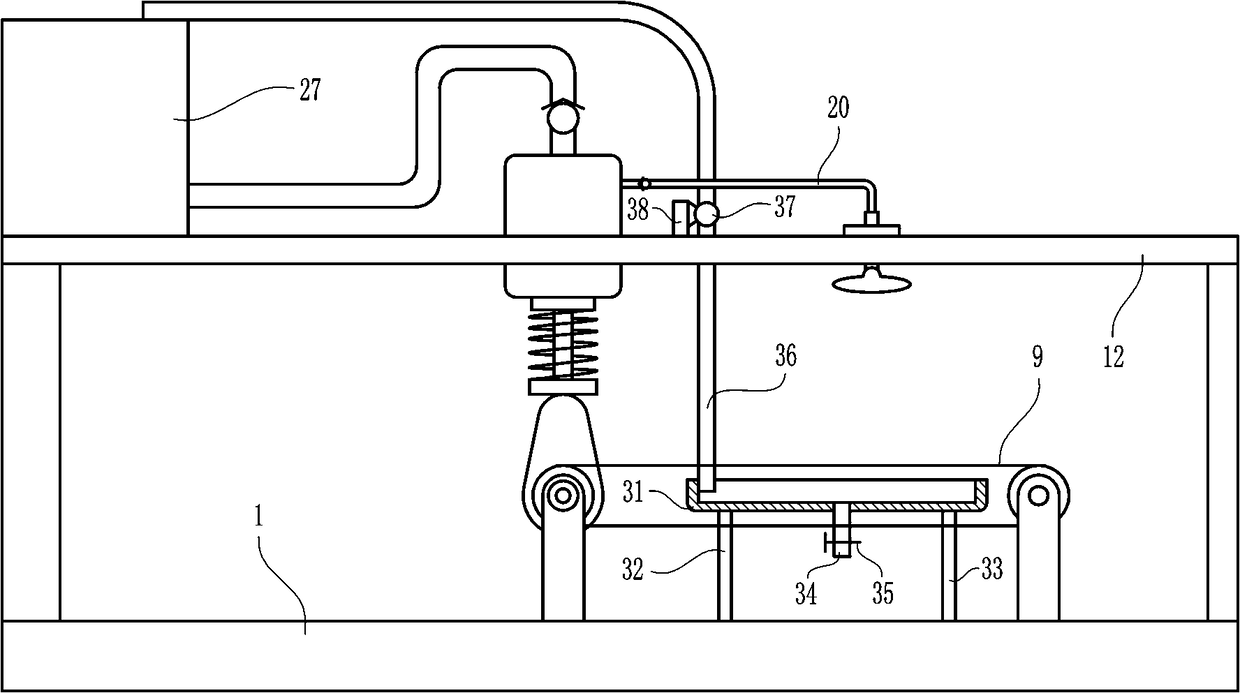

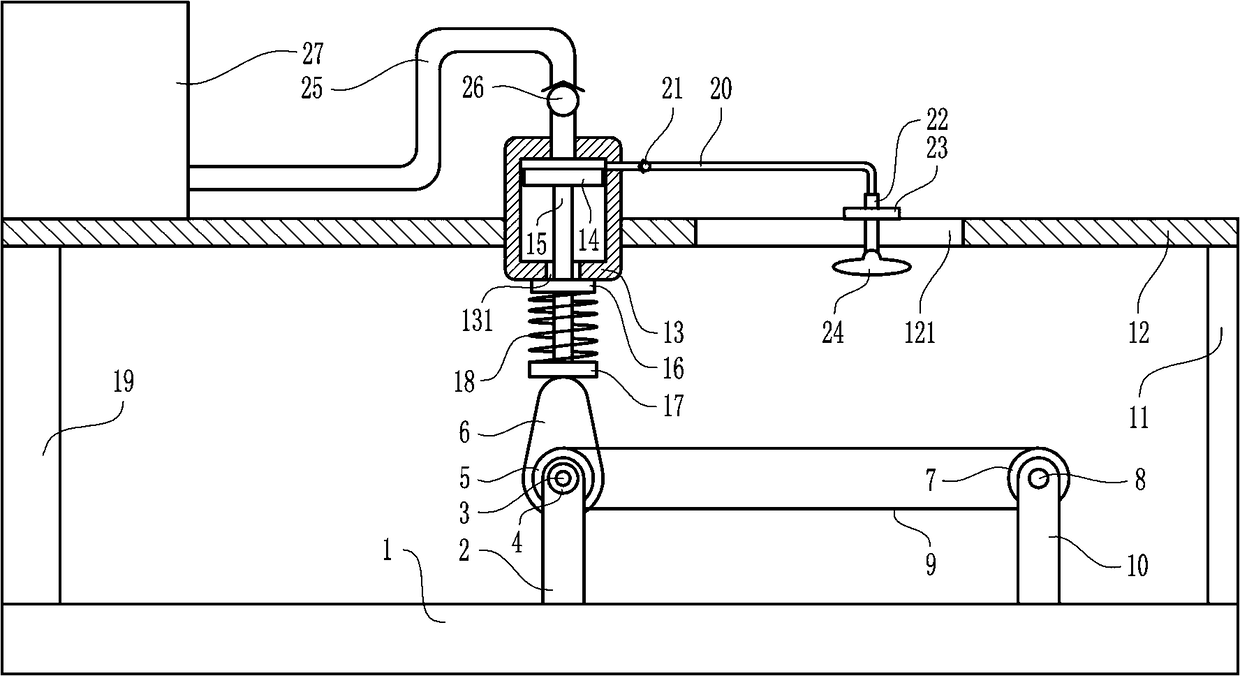

[0027] An oil spray antirust device for mechanical parts, such as Figure 1-5 As shown, it includes a base 1, a first small bracket 2, a first rotating shaft 3, a rotating wheel 4, a first sprocket 5, a cam 6, a second sprocket 7, a second rotating shaft 8, a chain plate 9, the first sprocket Two small brackets 10, the first big bracket 11, top plate 12, booster box 13, booster plate 14, lifting rod 15, gasket 16, contact plate 17, spring 18, second big bracket 19, hose 20, the first A one-way valve 21, slide pipe 22, slide plate 23, shower nozzle 24, first connecting pipe 25, second one-way valve 26 and large cylinder body 27, the top of base 1 is connected with the first small support 2, the first small support 2 is front and back symmetrical arrangement, the first rotating shaft 3 and the upper end of the first small bracket 2 are arranged to be rotationally connected, the front end of the first rotating shaft 3 is connected with the rotating wheel 4, and the first sprocket...

Embodiment 2

[0029] An oil spray antirust device for mechanical parts, such as Figure 1-5 As shown, it includes a base 1, a first small bracket 2, a first rotating shaft 3, a rotating wheel 4, a first sprocket 5, a cam 6, a second sprocket 7, a second rotating shaft 8, a chain plate 9, the first sprocket Two small brackets 10, the first big bracket 11, top plate 12, booster box 13, booster plate 14, lifting rod 15, gasket 16, contact plate 17, spring 18, second big bracket 19, hose 20, the first A one-way valve 21, slide pipe 22, slide plate 23, shower nozzle 24, first connecting pipe 25, second one-way valve 26 and large cylinder body 27, the top of base 1 is connected with the first small support 2, the first small support 2 is front and back symmetrical arrangement, the first rotating shaft 3 and the upper end of the first small bracket 2 are arranged to be rotationally connected, the front end of the first rotating shaft 3 is connected with the rotating wheel 4, and the first sprocket...

Embodiment 3

[0032] An oil spray antirust device for mechanical parts, such as Figure 1-5 As shown, it includes a base 1, a first small bracket 2, a first rotating shaft 3, a rotating wheel 4, a first sprocket 5, a cam 6, a second sprocket 7, a second rotating shaft 8, a chain plate 9, the first sprocket Two small brackets 10, the first big bracket 11, top plate 12, booster box 13, booster plate 14, lifting rod 15, gasket 16, contact plate 17, spring 18, second big bracket 19, hose 20, the first A one-way valve 21, slide pipe 22, slide plate 23, shower nozzle 24, first connecting pipe 25, second one-way valve 26 and large cylinder body 27, the top of base 1 is connected with the first small support 2, the first small support 2 is front and back symmetrical arrangement, the first rotating shaft 3 and the upper end of the first small bracket 2 are arranged to be rotationally connected, the front end of the first rotating shaft 3 is connected with the rotating wheel 4, and the first sprocket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com