Automatic cleaning device for photovoltaic solar cell panels

A solar panel and automatic cleaning technology, applied in photovoltaic power generation, photovoltaic modules, cleaning methods and appliances, etc., can solve problems such as increased workload of workers, affecting light energy conversion efficiency, and increasing operating costs of solar power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

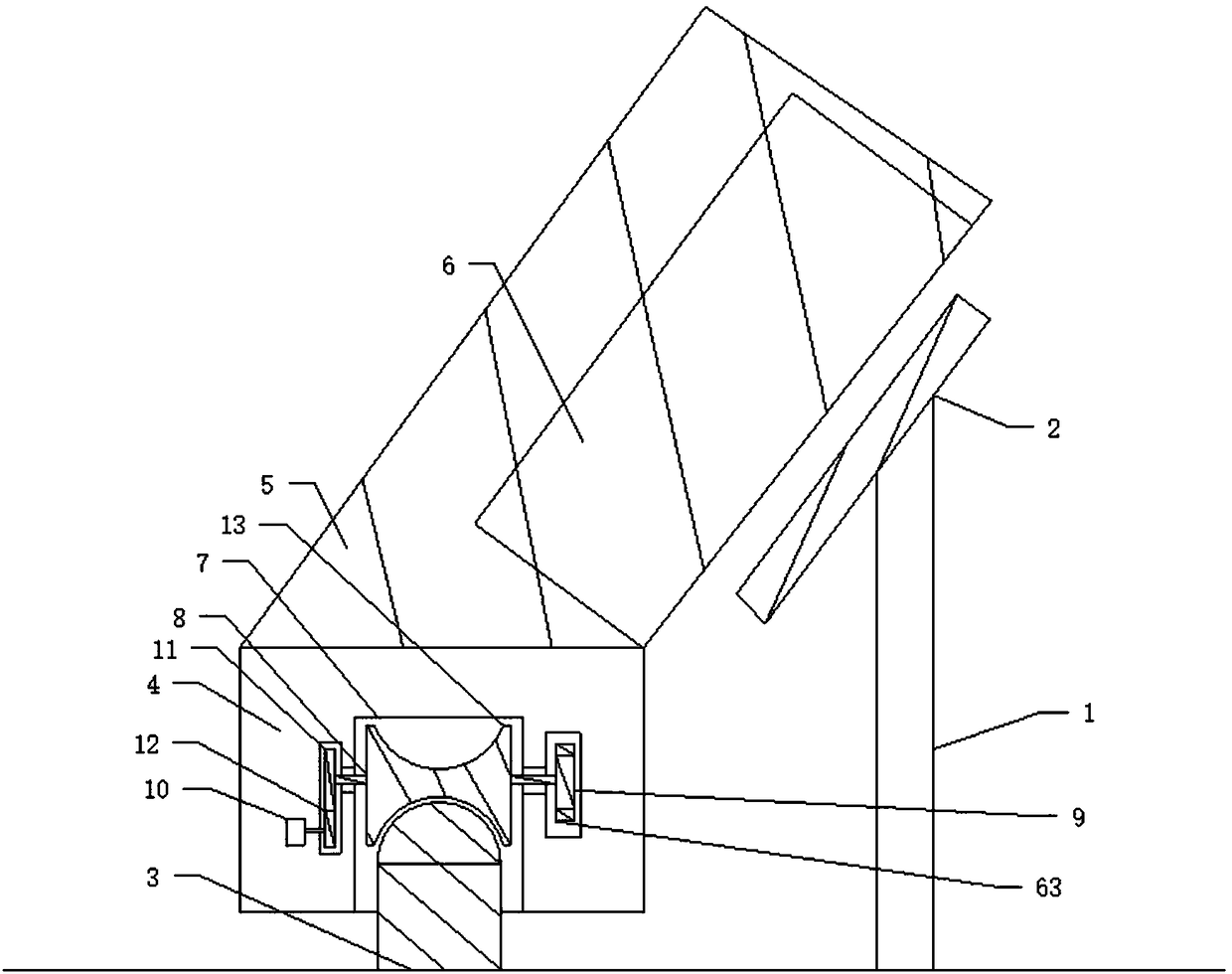

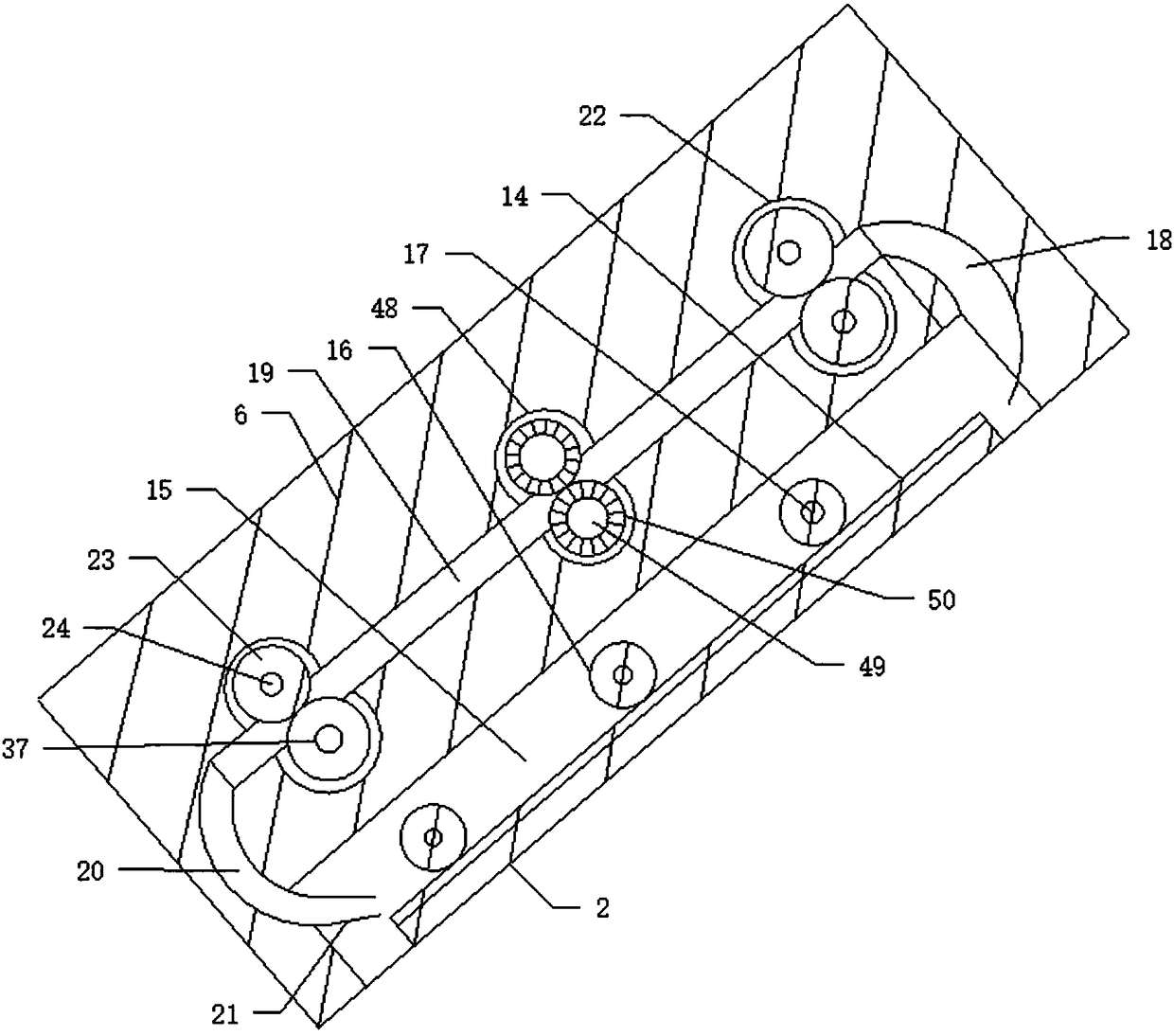

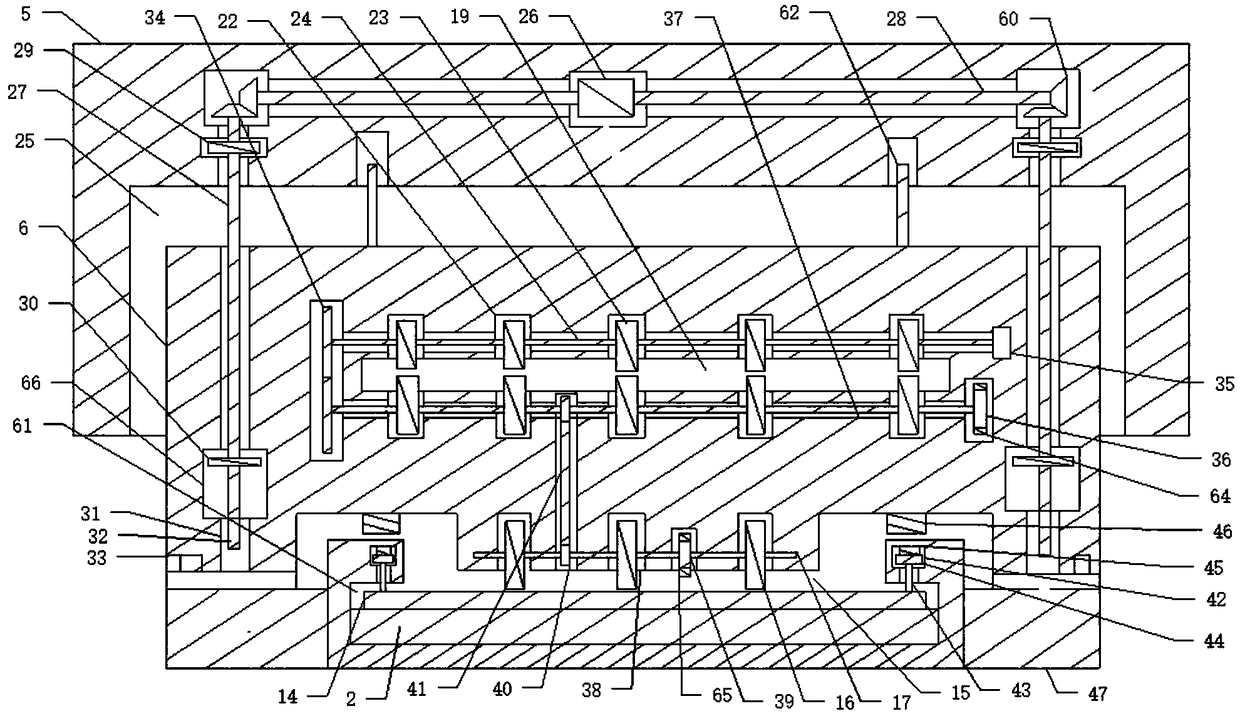

[0028] like Figure 1 to Figure 4 As shown, a photovoltaic solar cell panel automatic cleaning device includes supporting frames 1 arranged side by side, and fixing frames 47 are respectively arranged on the supporting frames 1, and solar cell panels 2 are respectively arranged on the fixing frames 47, and It includes rails 3 corresponding to the side-by-side support frames 1, a seventh slide groove 61 is respectively provided on both sides of the fixed frame 47, and a dust-proof film 14 is respectively provided on the solar cell panel 2, The dust-proof film 14 slides in the seventh chute 61 on both sides, and a row of fixed rods 43 sliding in the seventh chute 61 are arranged on both sides of the fixed frame 47 respectively. 43 pushes against the dust-proof film 14 respectively.

[0029] The fixing frame 47 can be set on the supporting frame 1, and the solar cell panel 2 can be arranged on the fixing frame 47, so that the solar cell panel 2 can be further supported and fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com