Method for preventing melt from reflowing for magnesium alloy casting liquid transfer and liquid transfer device

A magnesium alloy and liquid transfer technology, which is applied in the production and manufacture of magnesium alloy parts and in the field of magnesium, can solve the problems of reducing labor intensity, achieve the effects of reducing labor intensity, solving oxidation and blockage, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings.

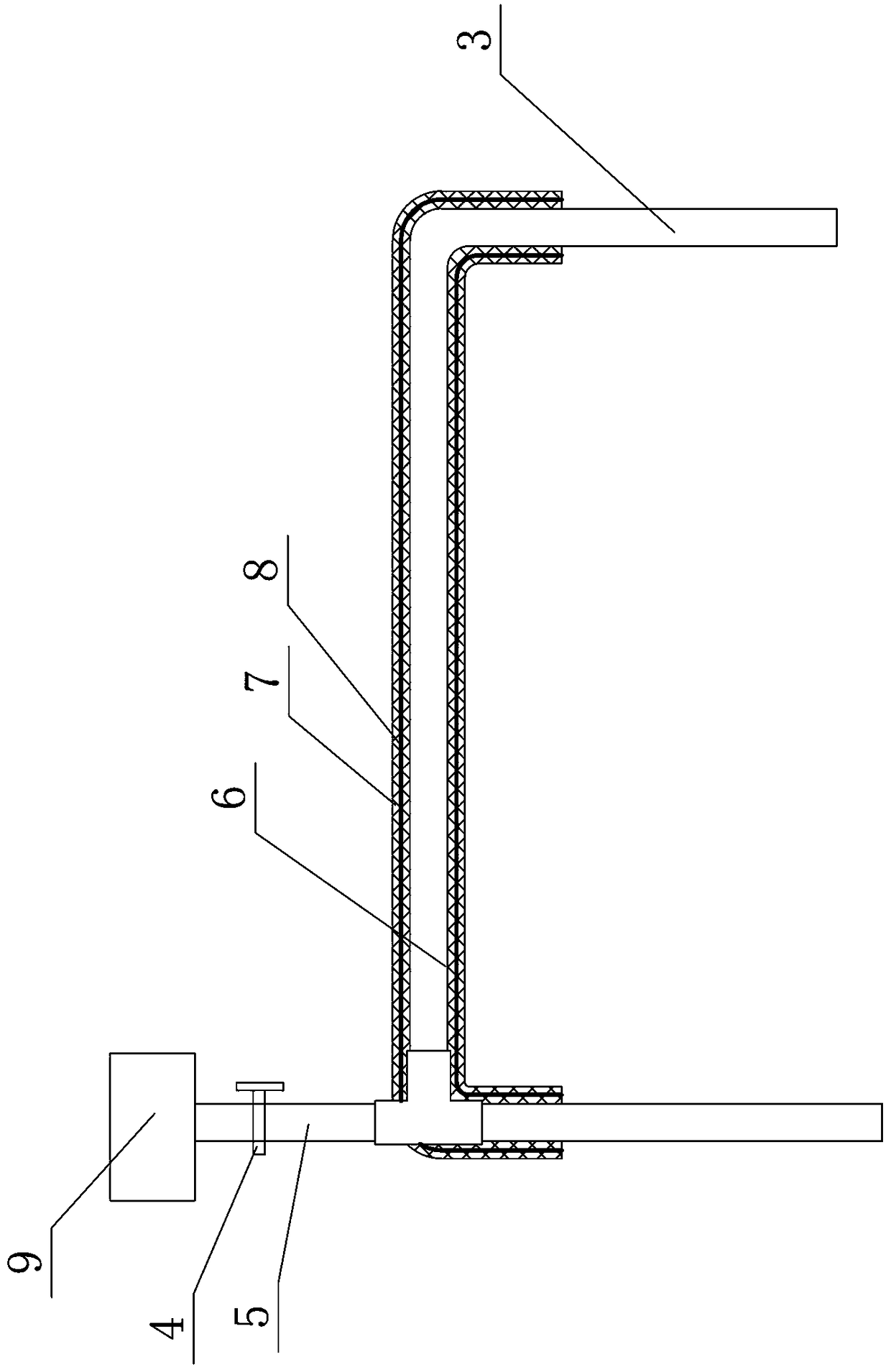

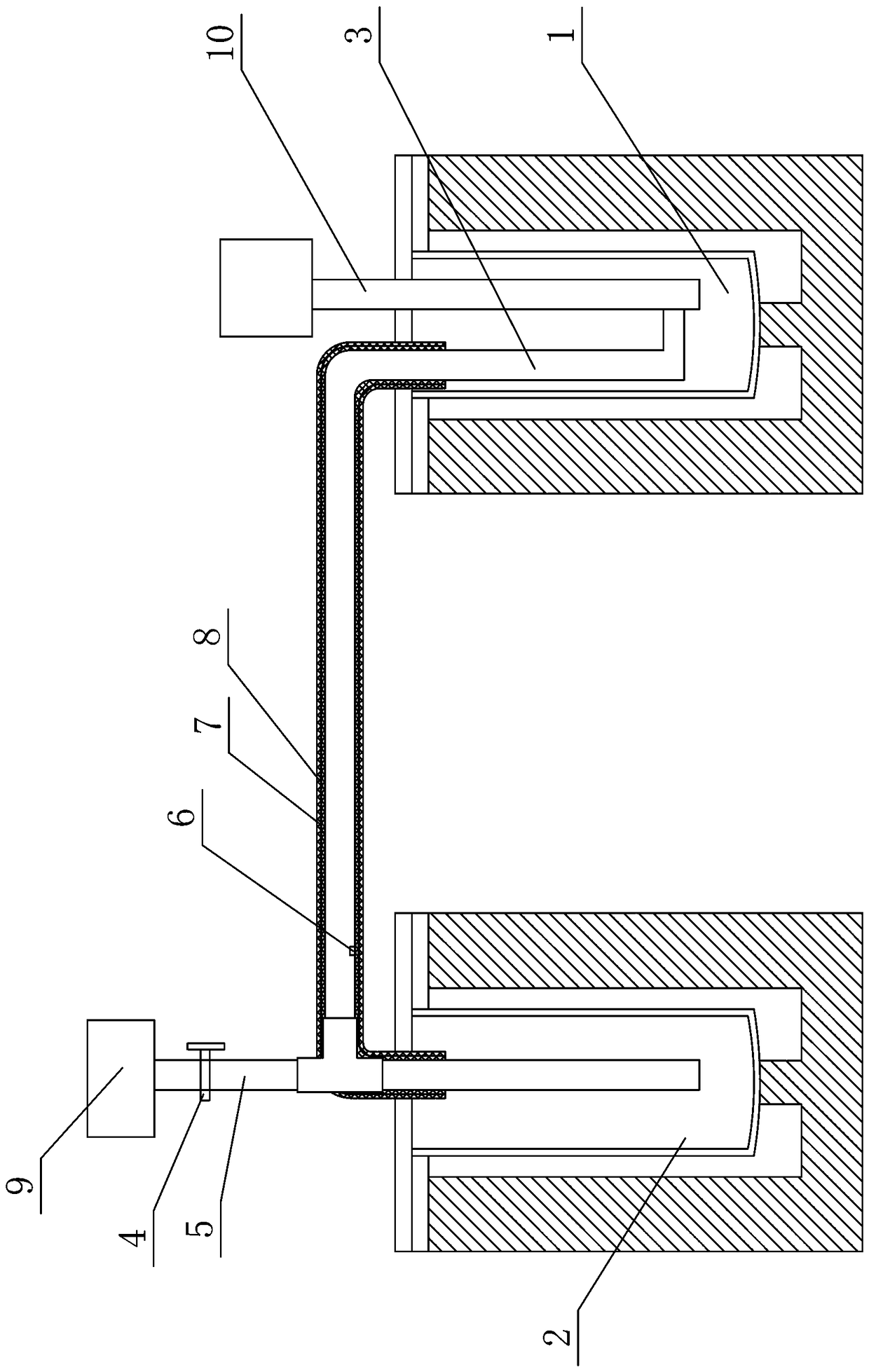

[0019] A method for preventing melt reflux for magnesium alloy melting and casting liquid transfer. By setting an air intake pipe 5 and an air intake valve 4 on the liquid transfer pipe 3, the air intake pipe 5 is connected to a protective gas source 9. When the magnesium alloy liquid transfer is completed, Open the intake valve 4, pass into the protective gas in the liquid transfer pipe 3, under the effect of the protective gas, the liquid level height of the magnesium alloy liquid in the liquid transfer pipe 3 located in the holding furnace 2 is the same as that of the magnesium alloy liquid in the holding furnace 2 The liquid level height of the alloy liquid is the same, and the liquid level height of the magnesium alloy liquid located in the liquid transfer pipe 3 in the refining furnace 1 is the same as the liquid level height of the magnesium alloy liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com