Injection moulding equipment

A technology of injection molding and equipment, applied in the direction of electrical components, electrical switches, circuits, etc., can solve problems such as waste, hidden safety hazards, and electricity consumption, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

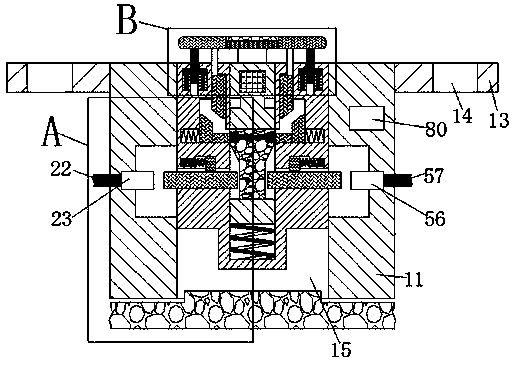

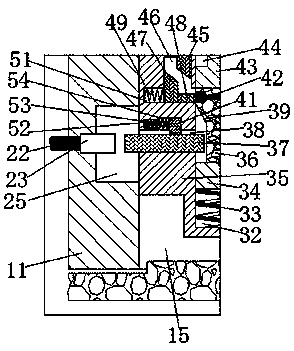

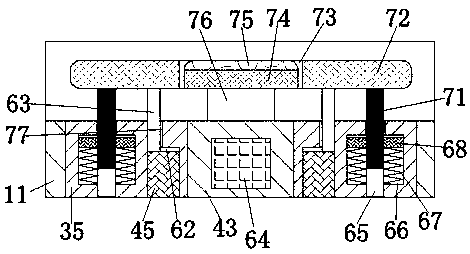

[0014] Such as Figure 1-Figure 5As shown, an injection molding equipment of the present invention includes a base 11, a power feeding device arranged in the base 11 and a locking device arranged in the base 11, and the power feeding device includes a set Up and down through the loading cavity 15 arranged in the base 11, the left and right of the loading cavity 15 are symmetrically provided with a countersunk 25 located in the loading cavity 15 and communicating with the loading cavity 15, and the sinking on the left side A first power feeding block 23 is fixedly arranged on the left inner wall of the mouth 25, and the left end of the first power feeding block 23 is fixedly connected to a power supply located in the base 11 and has one end extending out of the left end surface of the base 11. The outer first wire 22, the second power feeding block 56 is fixedly installed in the right inner wall of the right side of the counterbore 25, and the right end of the second power feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com