Mobile drum type automatic-tensioning electric freight winch

A drum-type, drum-type technology, applied in the field of mobile drum-type automatic tensioning electric freight winches, can solve the problems of unsatisfactory rope pressing mechanism, increased space and weight of the winch, unstable load of goods, etc., and achieves compact structure, reduced Wear and take up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

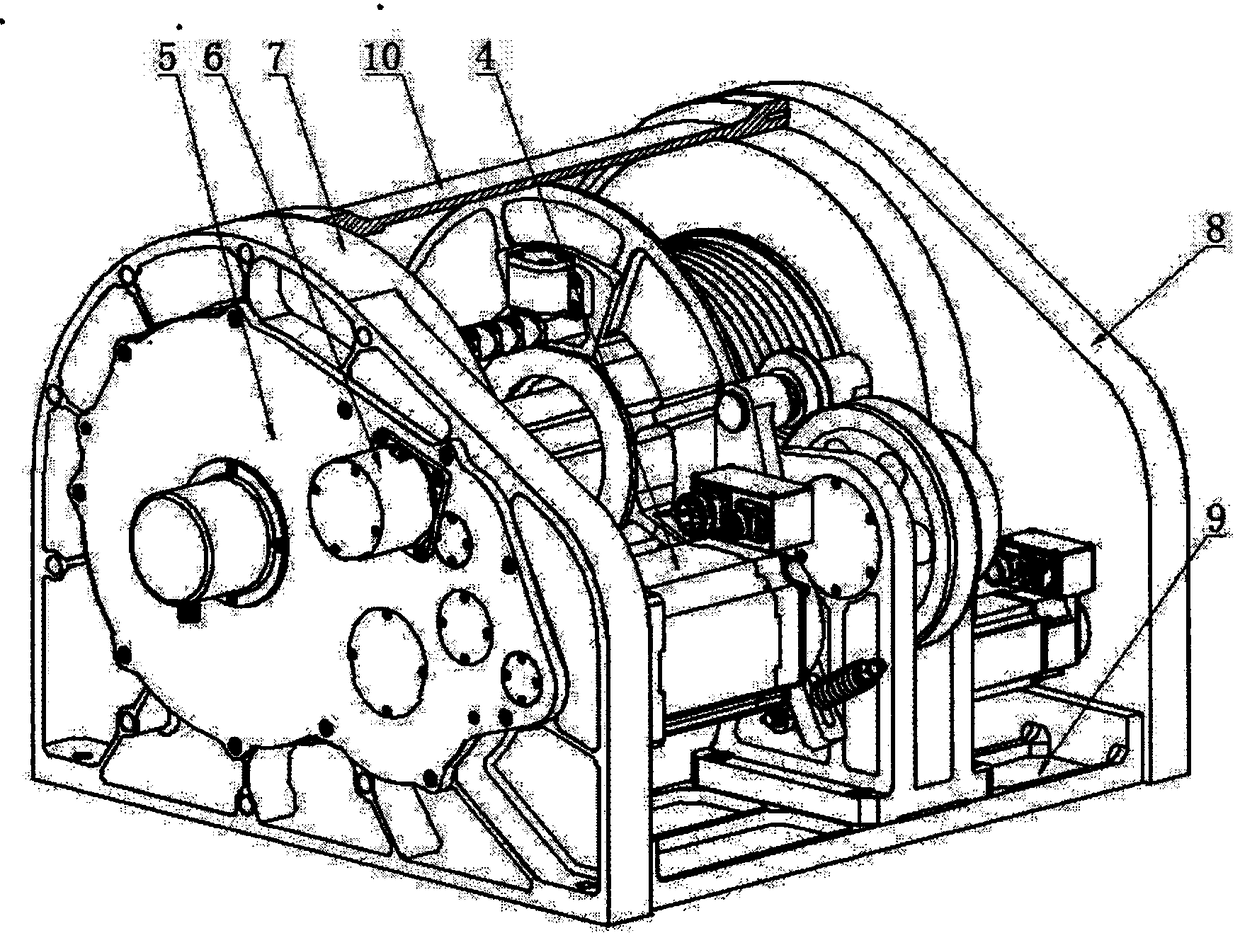

[0020] A mobile drum type automatic tensioning electric freight winch, including a drum assembly, a power transmission assembly, a tensioning mechanism and a housing;

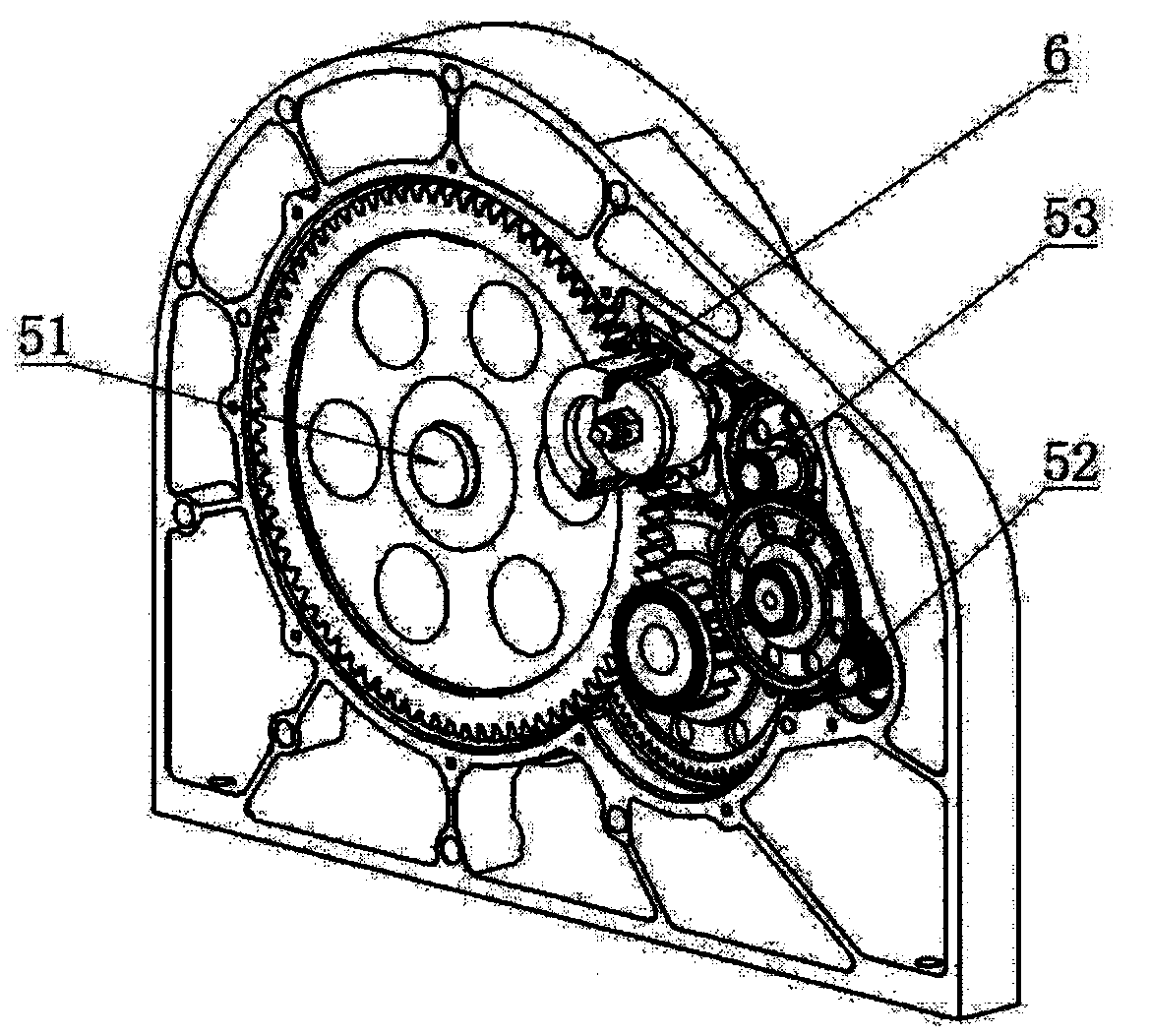

[0021] Such as figure 1 As shown, the housing is composed of a left bracket 7, a right bracket 8, a lower bracket 9 and a connecting cylinder 10. The left bracket 7 and the right bracket 8 are connected together through the connecting cylinder 10, and the lower bracket 9 is connected with the left bracket 7 and the right bracket by screws. 8 connected together;

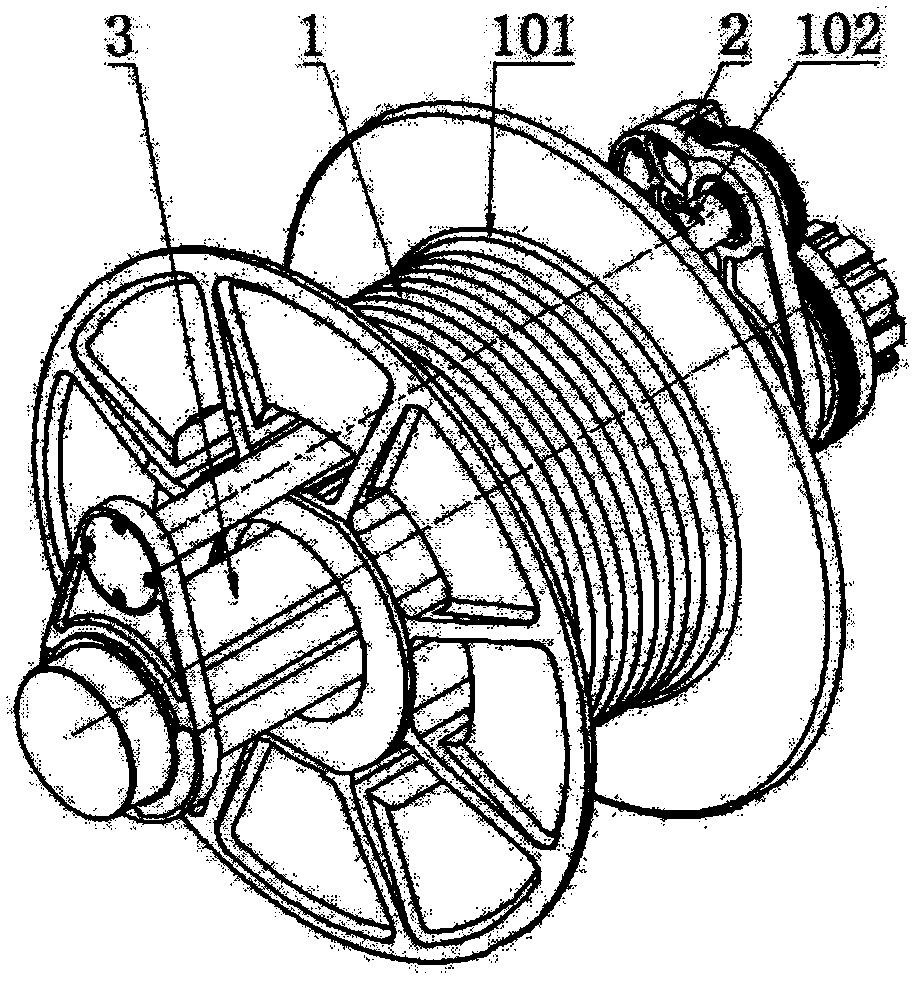

[0022] Such as figure 2 As shown, the connecting cylinder 10 has a built-in roller assembly. The roller assembly is composed of a roller 1, a moving roller mechanism 2 and a spline pair 3. The roller 1 and the moving roller mechanism 2 are fixed on the spline pair 3. The left and right sides of the spline pair 3 The end is installed on the left bracket 7 and the right bracket 8 through bearings; the side wall of the drum 1 is provided with a boss 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com