Bidirectional road monitoring equipment

A technology for monitoring equipment and roads, which is applied in the field of two-way road monitoring equipment, can solve problems such as increased costs and difficult maintenance, and achieve the effects of saving costs, reducing the number of equipment, and reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] As a basic example:

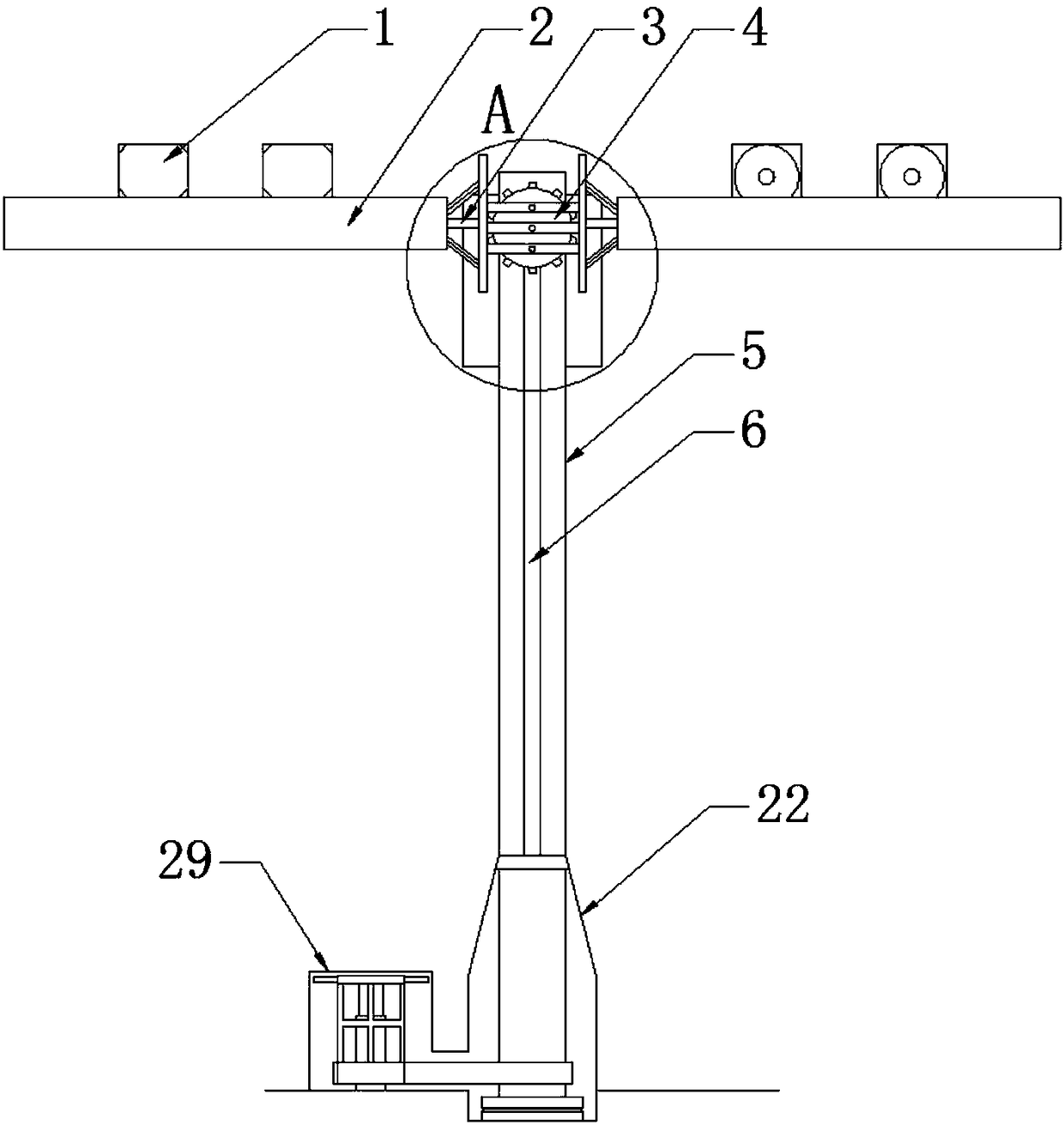

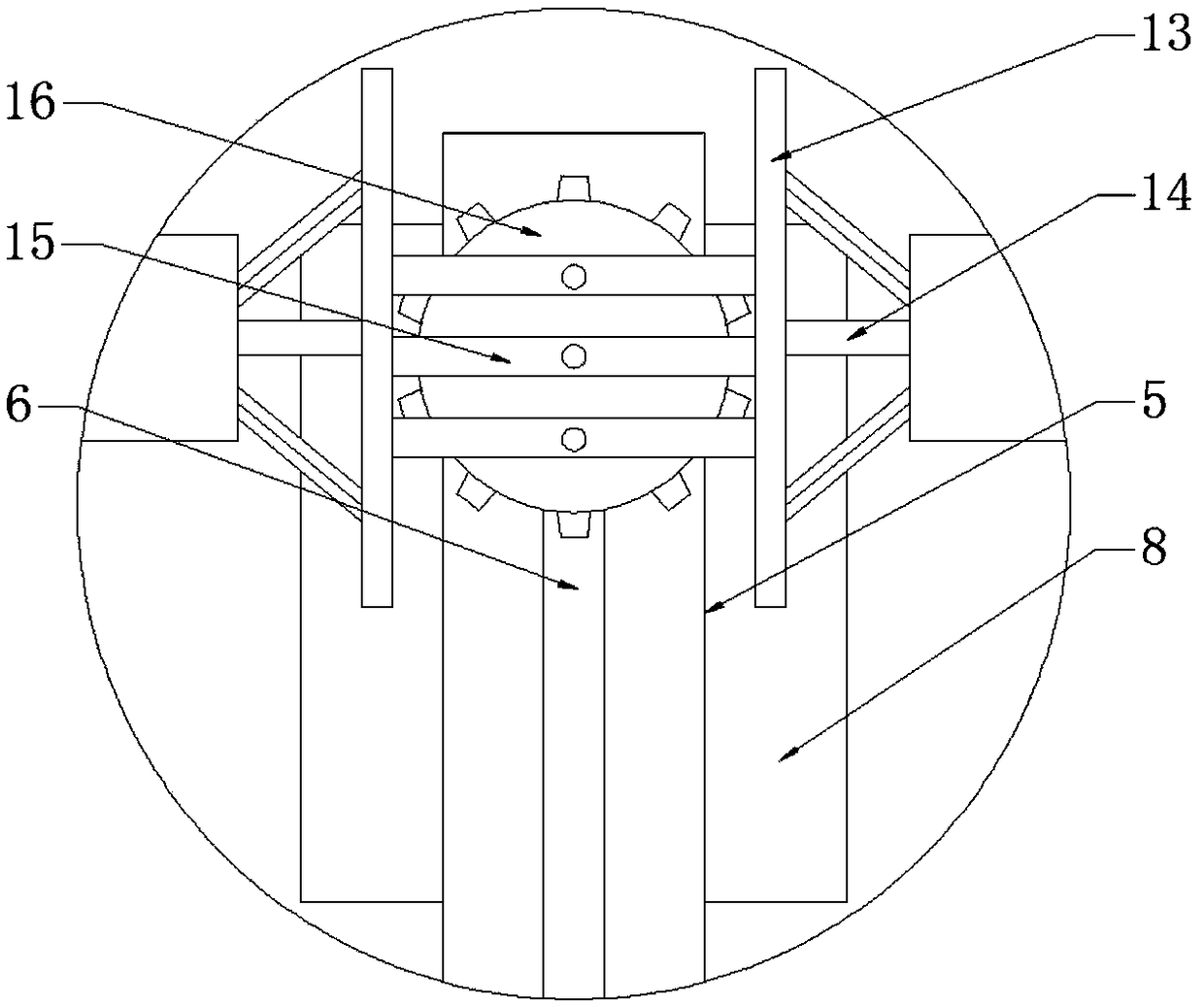

[0041] A two-way road monitoring equipment, comprising a pole 5, a connecting frame 3 is installed on the top of the vertical pole 5, and it is characterized in that a rotating device 4 is connected between the connecting frame 3 and the vertical pole 5, and the connecting frame 3 is also Connected with a movable rack bar 2, a camera 1 is installed on the movable rack bar 2, a central rotating rod 17 connected to the center of the rotating device 4 is installed in the vertical rod 5, and the central rotating rod 17 is connected with a snap-fit Device 11, pulley 10 is installed on the top and bottom in the vertical rod 5, conveyor belt 12 is installed on the pulley 10, the position corresponding to the clamping device 11 on the conveyor belt 12 is connected with a snap-in buckle 20, the vertical The lower end of the rod 5 is covered with a shield shell 22, the bottom of the vertical pole 5 in the shield shell 22 is connected with a rotating chassis ...

Embodiment 2

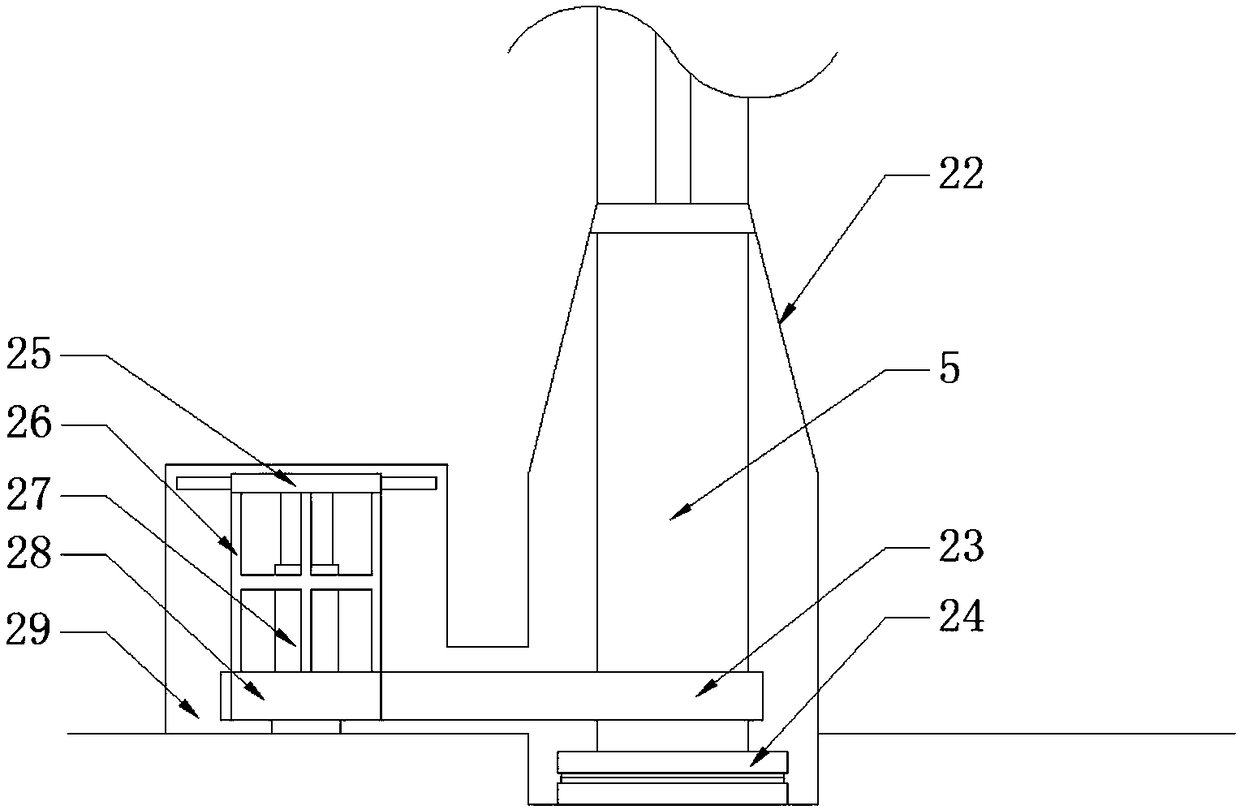

[0044] This embodiment focuses on the improvements compared with the above-mentioned embodiments, and the similarities will not be repeated. In this embodiment, the rotating handle plate 25 is disc-shaped, and the side of the rotating handle plate 25 is connected with multiple A handle, the bottom surface of the rotating handle plate 25 is also connected with a handle support platform 27, the handle intermediate frame 26 includes a plurality of vertical bars connected with the rotating handle plate 25, and a supporting ring is connected between the vertical bars, and the A transmission wheel 28 is also connected between the handle middle frame 26 and the transmission belt 23 .

[0045] The shape of the handle in this embodiment is convenient for maintenance personnel to operate manually without using complex tools, which simplifies the maintenance process. The transmission wheel 28 ensures a more reliable connection between the handle intermediate frame 26 and the transmission ...

Embodiment 3

[0047] This embodiment focuses on the improvements compared with the above-mentioned embodiments, and the similarities will not be repeated. In this embodiment, the rotating chassis 24 includes an upper chassis for supporting rotation and a lower chassis for fixing. The upper surface of the upper chassis is connected to the bottom of the vertical rod 5 , and the lower chassis is installed at the bottom of the shield shell 22 .

[0048] The rotating chassis 24 of this embodiment supports the vertical rod 5 to rotate in the horizontal direction, and cooperates with the shield shell 22 to prevent the vertical rod 5 from tilting or shifting when rotating, which enhances the stability of the equipment operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com