High-efficiency fire extinguishing system applicable to highly gassy mine shaft

A technology of fire extinguishing system and wellbore, which is applied in mine/tunnel ventilation, mining equipment, mining equipment, etc. It can solve problems such as loss of employees’ lives and property of enterprises, untimely fire extinguishing, lack of anti-wind means and fire extinguishing means, etc., to increase Oxygen content, ensure safety, and the effect of no casualties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

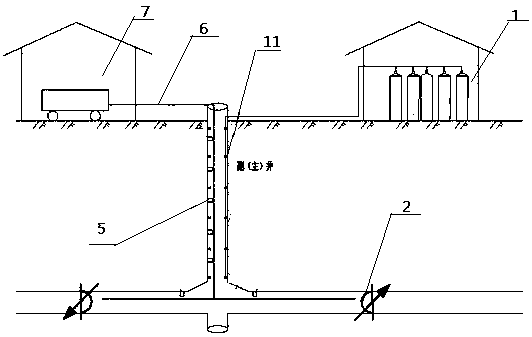

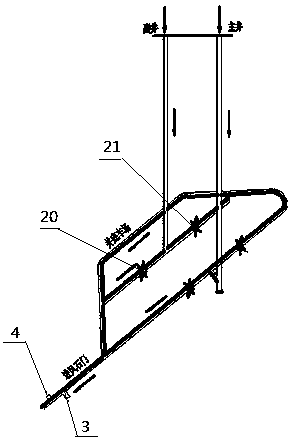

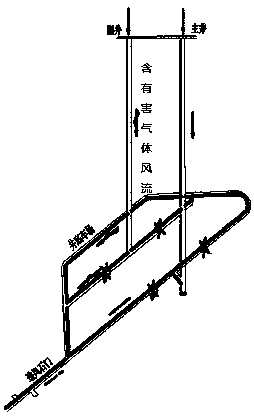

[0020] Such as Figure 1-3 As shown, the high-efficiency fire extinguishing system suitable for high-gas mine shafts includes a carbon dioxide fire extinguishing system in the shaft, a shaft air intake air volume control system, an underground harmful gas treatment system and a mine online monitoring system.

[0021] The carbon dioxide fire extinguishing system in the shaft includes a carbon dioxide storage station 1 and a number of annular carbon dioxide gas outlets 11 arranged on the ground near the mine, and an annular carbon dioxide gas outlet is arranged at a certain distance from top to bottom on the inner wall of the shaft to the horse head door at the bottom of the shaft. The gas outlet 11 and several annular carbon dioxide gas outlets 11 are all connected in parallel with the carbon dioxide storage station 1, and an independent control switch i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com